Production method of extruder screw

A production method and screw technology, which are applied in the production field of extruder screws, can solve the problems of complex processing, low productivity and high production cost, and achieve the effects of reducing costs, improving efficiency and qualification rate, and simplifying design and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

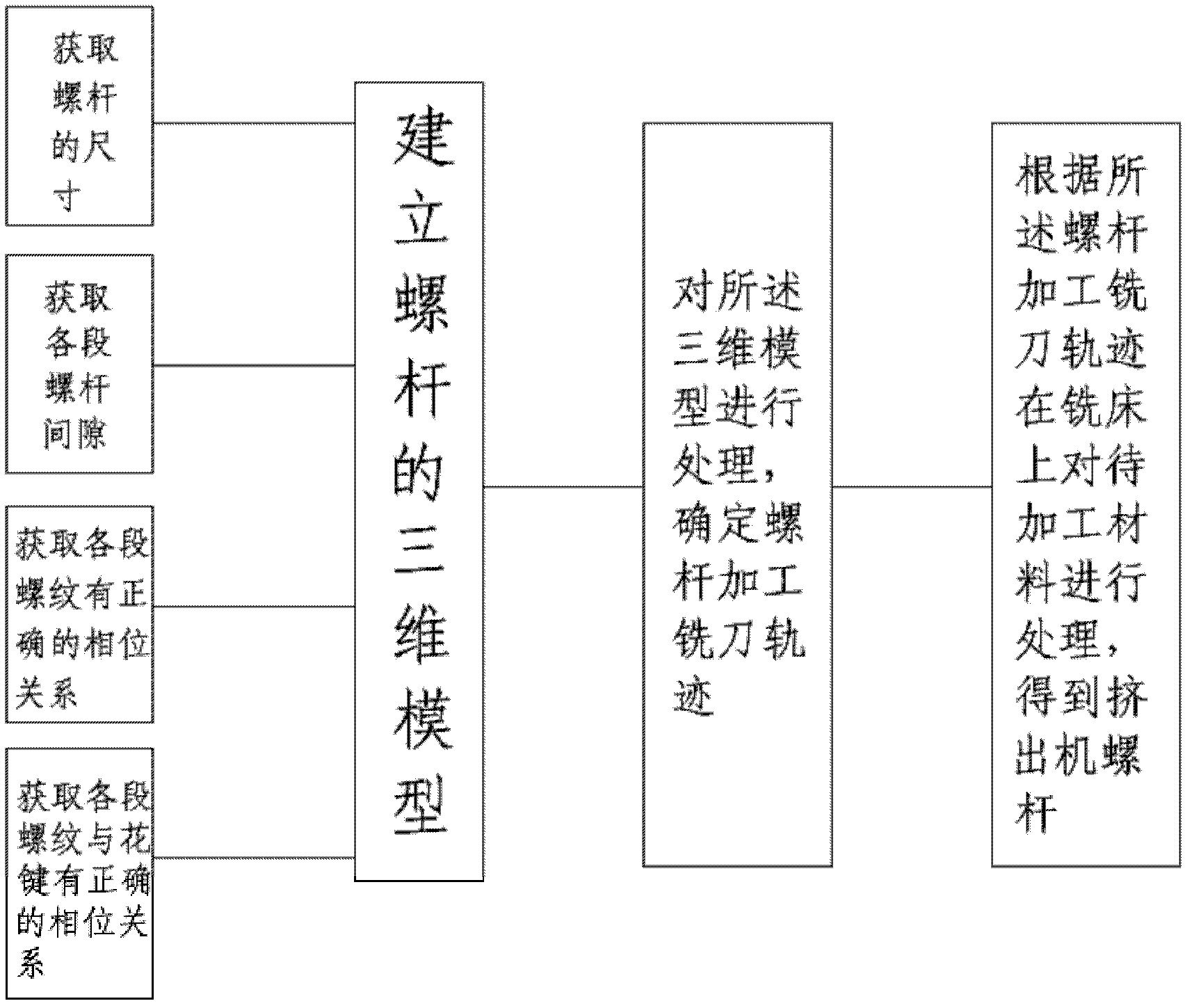

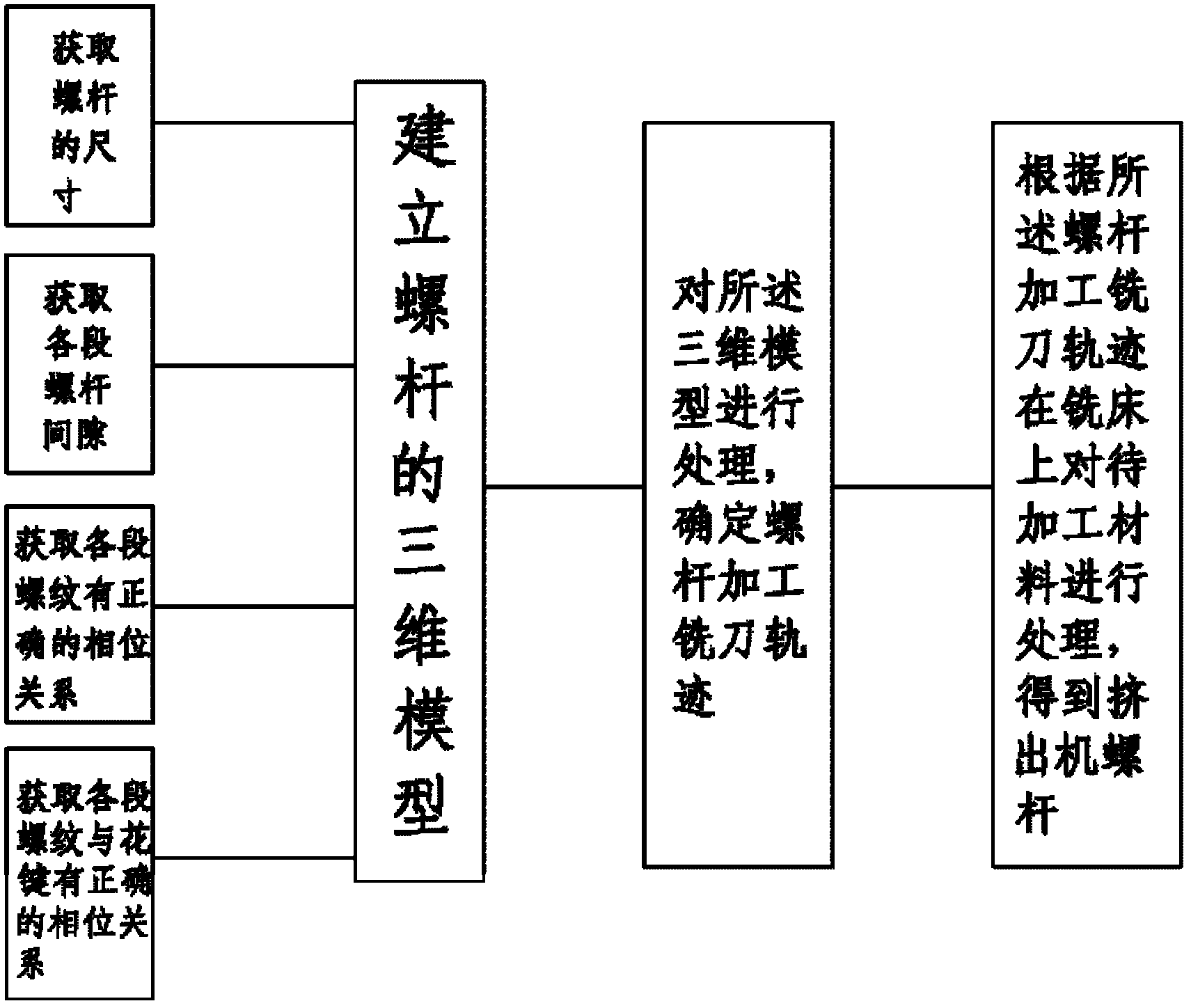

[0019] The production method of a kind of extruder screw rod of the present invention is as figure 1 As shown, according to the theoretical calculation, the statistical technical data of various existing screws at home and abroad and the experience of practical test run determine the screw parameters. Include the following steps:

[0020] Step 1, obtain the accurate screw rod size;

[0021] Step 2, obtaining accurate screw clearances of each section;

[0022] Step 3, obtain the correct phase relationship of each thread;

[0023] Step 4, obtain the correct phase relationship between each thread and the spline;

[0024] Step 5, establishing a three-dimensional model of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com