Coupler socket mechanical life detection device and method

A technology of mechanical life and detection devices, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of high labor intensity for operators, inaccurate detection results, and inapplicability to the current production situation, etc., to achieve improved testing efficiency, large promotion range, The effect of improving test accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

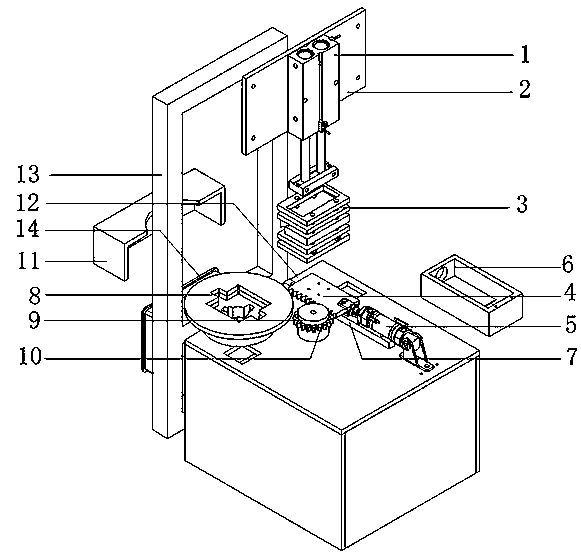

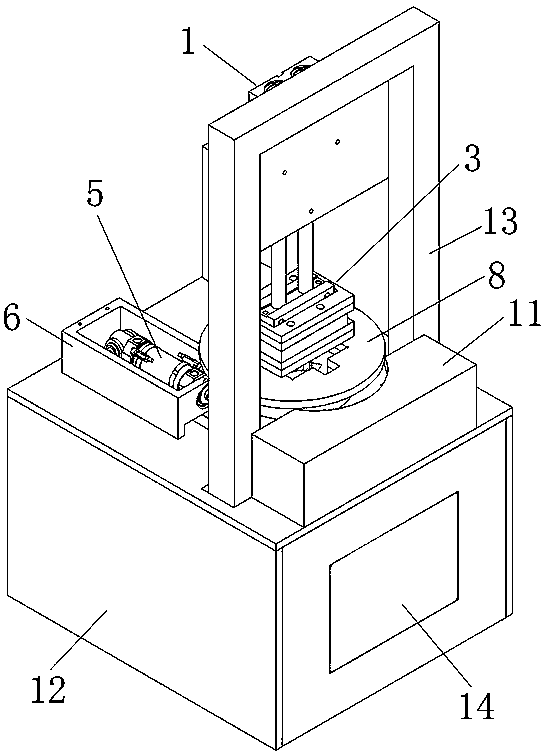

[0020] Embodiment 1: A coupler socket mechanical life detection device.

[0021] An automatic detection device for the mechanical life of a coupler socket includes four parts: a pressing and positioning mechanism, a pushing mechanism, a rotating mechanism, and a main body mechanism.

[0022] The pressing and positioning mechanism is used to assemble the plug to the coupler socket. The pressing and positioning mechanism includes a pressing cylinder 1, a pressing cylinder fixing plate 2 and a plug fixing plate 3. The pressing cylinder fixing plate 2 is arranged on the main body mechanism Above, the compression cylinder 1 is installed on the compression cylinder fixing plate 2, and the plug fixing plate 3 is installed on the bottom of the compression cylinder 1 push rod. The installation position of the compression cylinder fixing plate 2 can be adjusted up and down, and it is only necessary to adjust the up and down position of the compression cylinder 1 during the first commiss...

Embodiment 2

[0027] Embodiment 2: A method for detecting the mechanical life of a coupler socket.

[0028] A method for detecting the mechanical life of a coupler socket, the specific operation steps are as follows:

[0029] The operator picks up the coupler socket and puts it into the coupler socket fixing plate 8 to start "loading", and then the operator touches the "reset in place" button in the display 14, and the device will automatically reset. When the reset is in place, "reset" The "in place" button is displayed in green, otherwise it is red. Only when the operator presses the "start" button when the reset is in place can the device be tested, otherwise it will not act.

[0030] After the operator presses the "Start" button on the display screen, the cylinder 1 is pressed down, and the coupler plug can be accurately inserted into the coupler socket in the coupler socket fixing plate 8, simulating manual insertion of the plug into the socket. After the compression cylinder 1 is low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap