Rubber mould self-adaptive regulator for producing rubber product with metal frame

A self-adaptive adjustment, rubber mold technology, applied in the field of mold devices, to achieve the effect of reducing size error, prolonging service life and reducing rubber loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

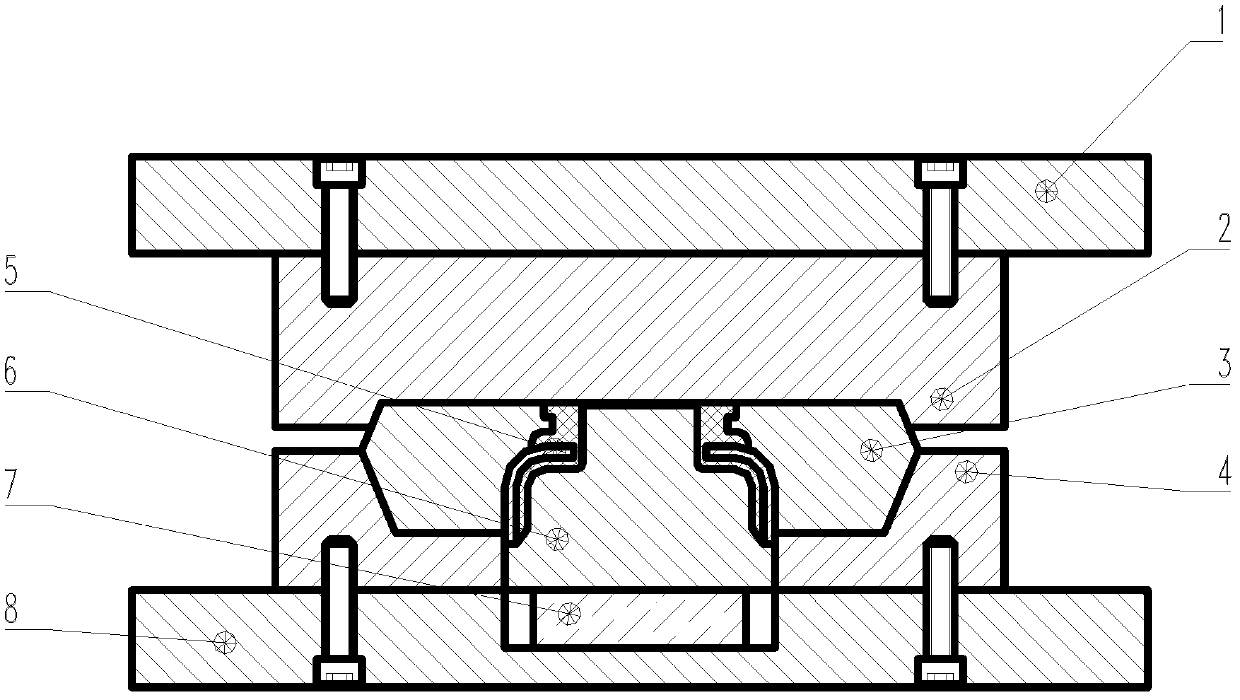

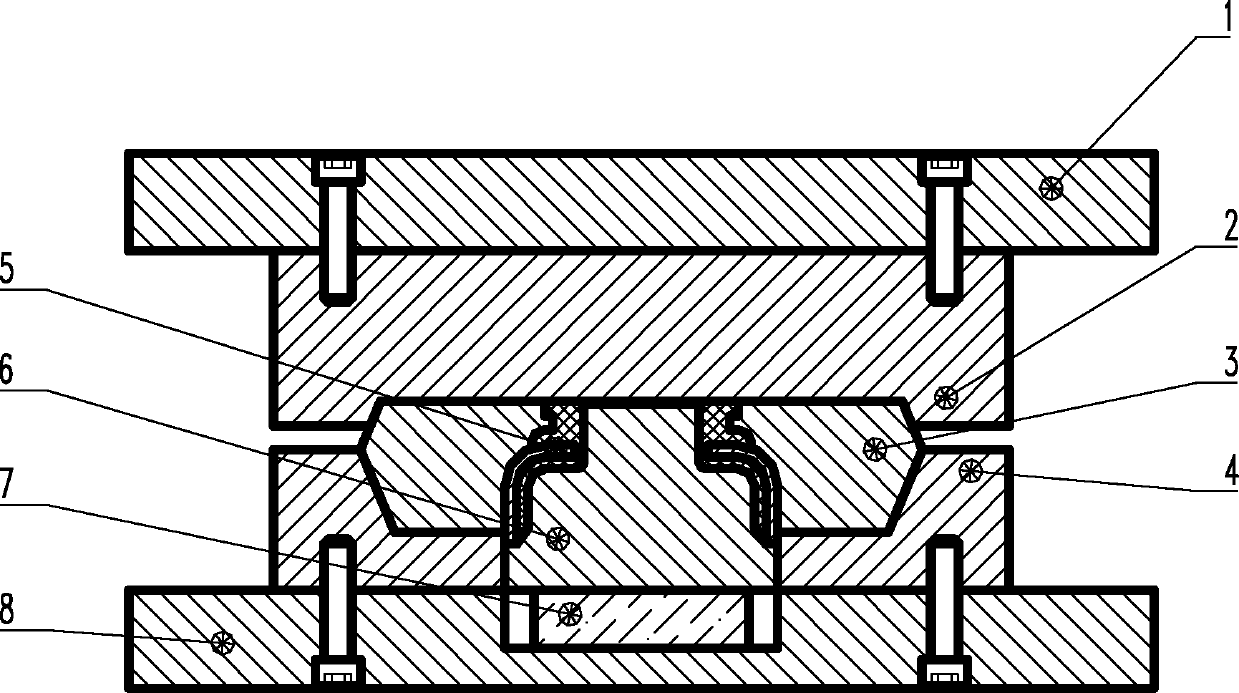

[0014] Such as figure 1 As shown, a kind of rubber mold self-adaptive adjustment device of the present invention produces band metal skeleton rubber product, comprises upper fixed plate 1, lower fixed plate 8, the upper mold 2 that is connected with upper fixed plate 1 and lower fixed plate 8 respectively and The lower mold 4, the Hafur 3 located between the upper mold 2 and the lower mold 4, the core insert 6 for matching with the Hafur 3, a groove is provided on the lower fixing plate 8, and a thermal expansion body is placed in the groove 7. The upper fixing plate 8, the upper mold 2, the lower fixing plate 8, and the lower mold 4 are respectively connected by screws. Hafu 3 refers to a split structure, usually divided into two halves. When Huff 3 is demolded, the two halves of the split mold cavity are opened first. At this time, the injection molded part is gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com