Core of composite rib box molding mold of helicopter rudder and manufacturing method of core

A technology for composite materials and forming molds, which is applied to the improvement of cores and the field of core manufacturing. It can solve the problems of partial layup displacement, small gaps, composite material rib boxes, etc., and achieve large thermal expansion coefficients, large thermal expansion coefficients, Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

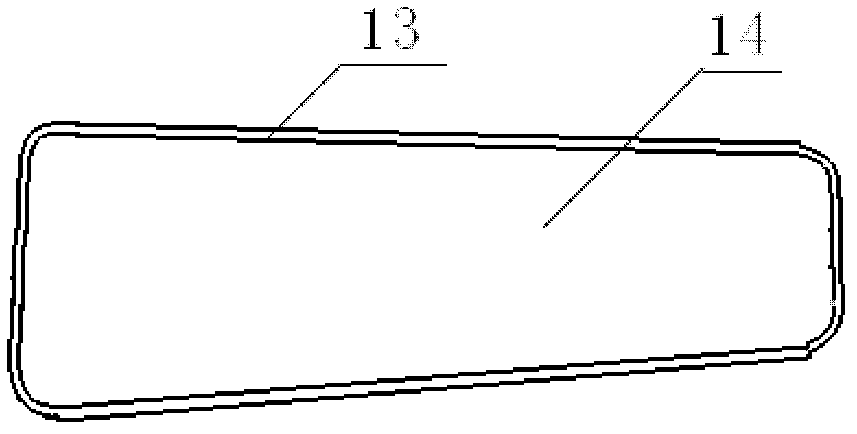

[0027] Embodiment 1, the length of the rib box to be formed is 200mm, the width is 150mm, the height is 30mm, and the wall thickness is 0.8mm.

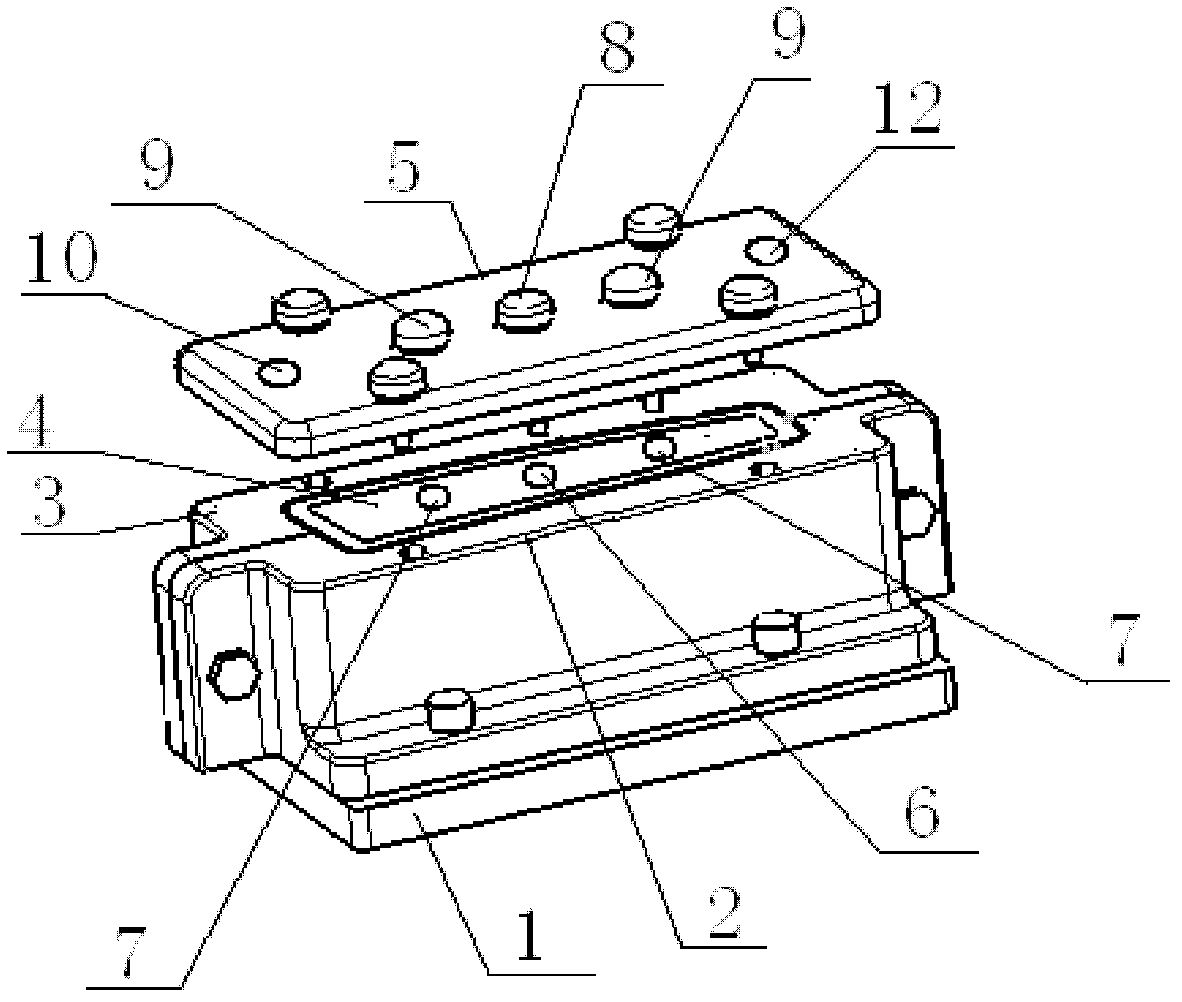

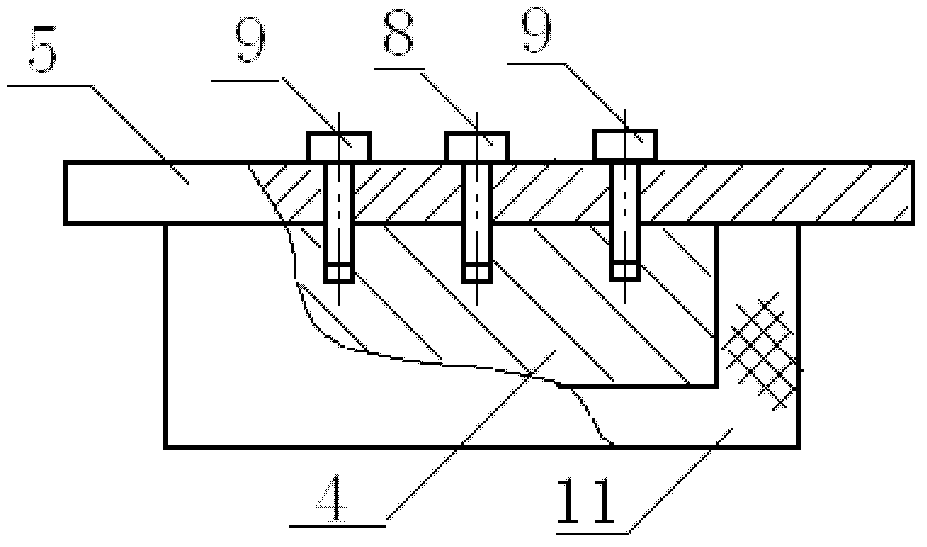

[0028] 1. Manufacture the metal inner core: the distance t=5mm between the lower surface of the metal inner core 4 and the upper surface of the rib box of the helicopter rudder composite material on the bottom plate 1 of the forming mold, the side surface of the metal inner core 4 and the helicopter rudder composite material The distance between the side walls of the inner cavity of the rib box is 5mm;

[0029] 2. Install the metal inner core;

[0030] 3. Paving and affixing helicopter rudder composite material rib box craft parts: the wall thickness of helicopter rudder composite material rib box craft parts is 1.3mm, and other dimensions are the same as those of the finished helicopter rudder composite material rib box;

[0031] 4. Pouring silicone rubber; the grade of pouring silicone rubber is RTV1556A;

[0032] 5. Curing: The s...

Embodiment 2

[0033]Embodiment 2, the rib box to be formed has a length of 320mm, a width of 170mm, a height of 50mm and a wall thickness of 1.8mm.

[0034] 1. Manufacture the metal inner core: the distance t=6.5mm between the lower surface of the metal inner core 4 and the upper surface of the rib box of the helicopter rudder composite material on the base plate 1 of the forming mold, and the side of the metal inner core 4 is composited with the helicopter rudder The distance between the side walls of the cavity of the material rib box is 6.5mm;

[0035] 2. Install the metal inner core;

[0036] 3. Paving and affixing helicopter rudder composite material rib box craft parts: the wall thickness of the helicopter rudder composite material rib box craft parts is 2.5mm, and other dimensions are the same as those of the finished helicopter rudder composite material rib box;

[0037] 4. Pouring silicone rubber; the grade of pouring silicone rubber is RTV1502A;

[0038] 5. Curing: Carry out sil...

Embodiment 3

[0039] Embodiment 3, the length of the rib box to be formed is 400mm, the width is 180mm, the height is 80mm, and the wall thickness is 2.8mm.

[0040] 1. Manufacture the metal inner core: the distance between the lower surface of the metal inner core 4 and the upper surface of the rib box of the helicopter rudder composite material on the bottom plate 1 of the forming mold is t=7.5mm, and the side of the metal inner core 4 is composited with the helicopter rudder The distance between the side walls of the cavity of the material rib box is 7.5mm;

[0041] 2. Install the metal inner core;

[0042] 3. Paving and affixing helicopter rudder composite material rib box craft parts: the wall thickness of helicopter rudder composite material rib box craft parts is 3.8mm, and other dimensions are the same as those of the finished helicopter rudder composite material rib box;

[0043] 4. Pouring silicone rubber; the grade of pouring silicone rubber is R10301;

[0044] 5. Curing: Carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com