Large-tonnage multi-winding-ratio traction elevator

A technology with multiple winding ratios and large tonnage, which is applied to elevators, transportation and packaging in buildings, which can solve the problems that elevators cannot meet the requirements and achieve the effect of reducing the amount of deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

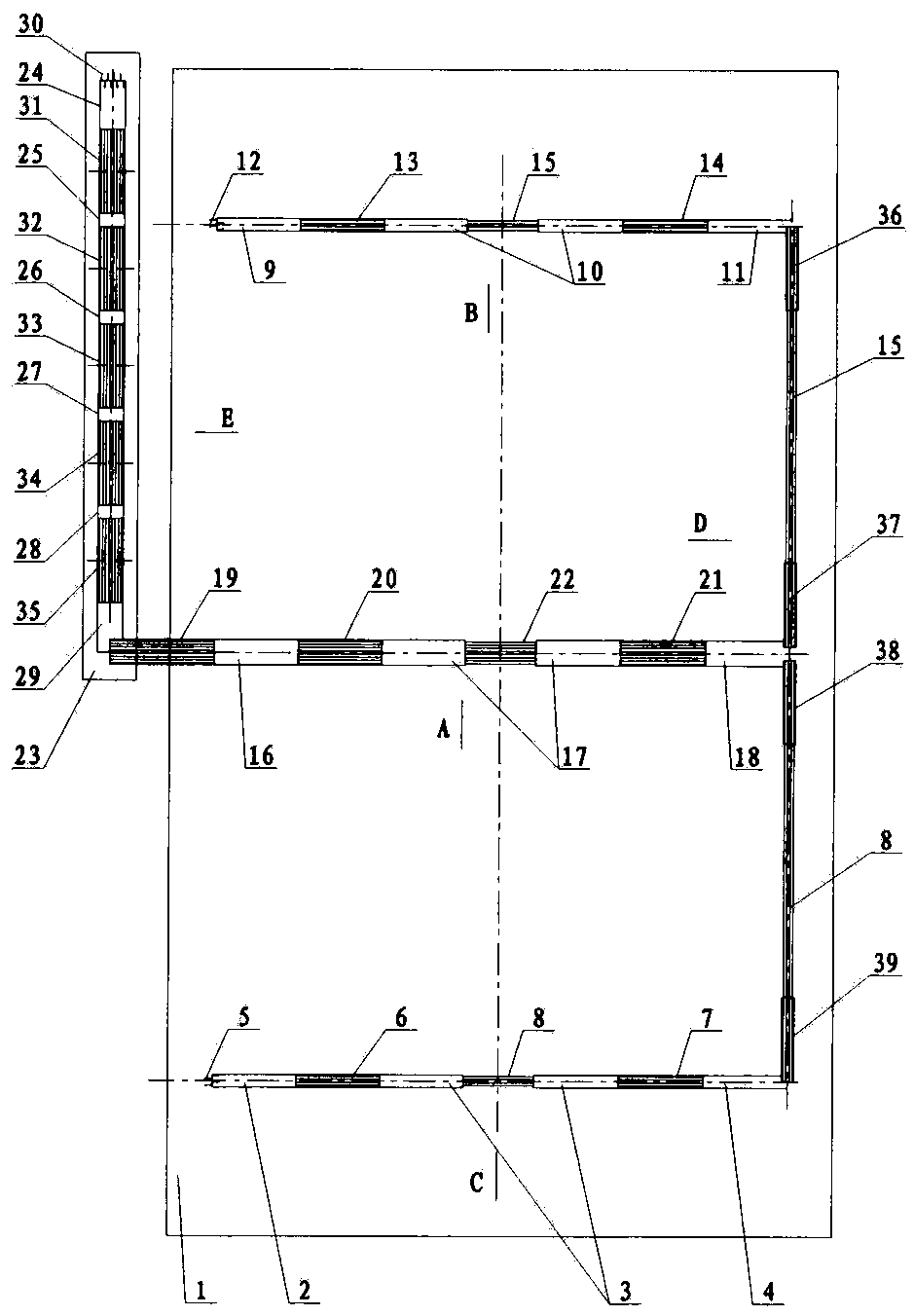

[0035] Embodiment 1: Large-tonnage elevator 12:1 roping mode.

[0036] Embodiment 1 Explanation of reference numerals:

[0037] 1-car, 2-fourth car top sheave assembly, 3-fifth car top sheave assembly, 4-sixth car top sheave assembly, 5-A-share traction rope head device, 6-third car top sheave assembly Car side fixed pulley assembly, 7-fourth car side fixed pulley assembly, 8-A-share traction rope, 9-seventh car top sheave assembly, 10-eighth car top sheave assembly, 11-ninth car top sheave assembly Top sheave assembly, 12-B strand traction rope head device, 13-Fifth car side fixed pulley assembly, 14-Sixth car side fixed pulley assembly, 15-B strand traction rope, 16-First car Top sheave assembly, 17-second car top sheave assembly, 18-third car top sheave assembly, 19-traction machine, 20-first car side fixed pulley assembly, 21-second car side fixed Pulley assembly, 22-traction rope, 23-counterweight, 24-sixth counterweight sheave assembly, 25-fifth counterweight sheave as...

Embodiment 2

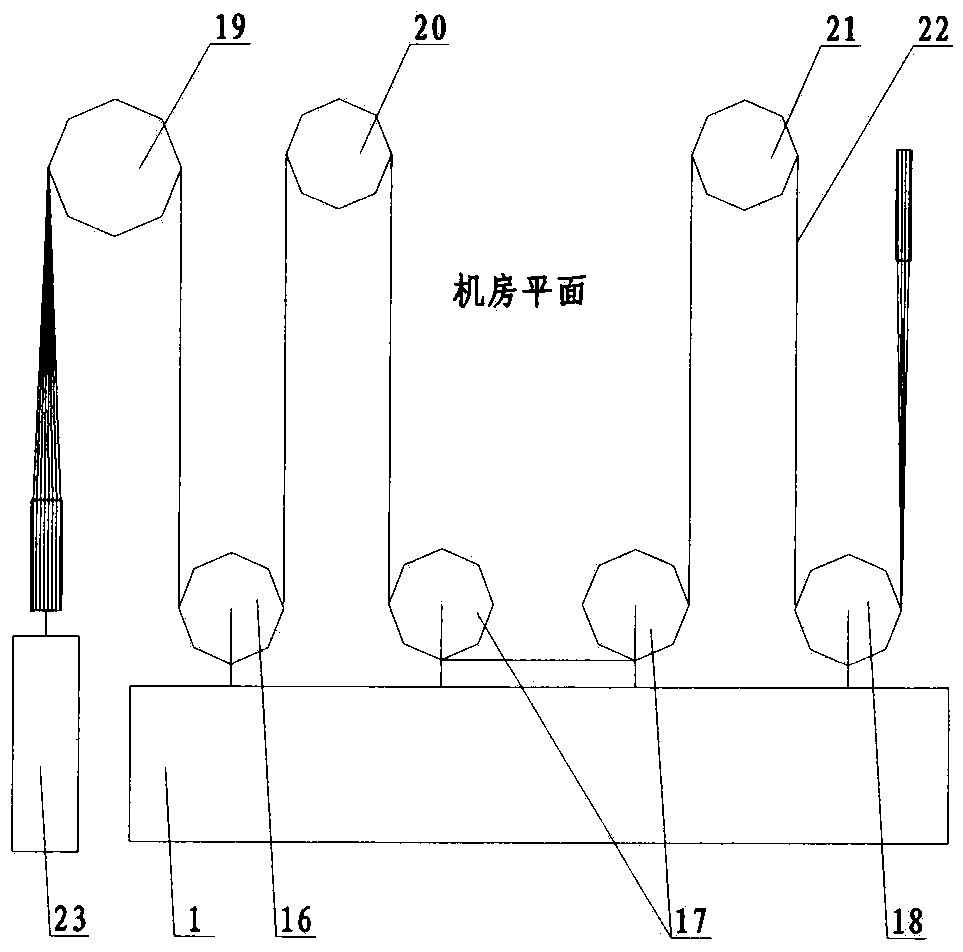

[0046] Embodiment 2: Large tonnage elevator 8:1 roping mode.

[0047] Embodiment 2 Explanation of reference numerals:

[0048] 1-car, 2-third car top sheave assembly, 3-fourth car top sheave assembly, 4-A-share traction rope head device, 5-second car side fixed pulley assembly, 6-A-share Traction rope, 7-fifth car top sheave assembly, 8-sixth car top sheave assembly, 9-B strand traction rope end device, 10-third car side fixed pulley assembly, 11-B strand traction Traction rope, 12-first car top sheave assembly, 13-second car top sheave assembly, 14-traction machine, 15-first car side fixed pulley assembly, 16-traction rope, 17-counterweight , 18-the fourth counterweight sheave assembly, 19-the third counterweight sheave assembly, 20-the second counterweight sheave assembly, 21-the first counterweight sheave assembly, 22-the traction rope head on the counterweight side device, 23-the third counterweight side fixed pulley assembly, 24-the second counterweight side fixed pulle...

Embodiment 3

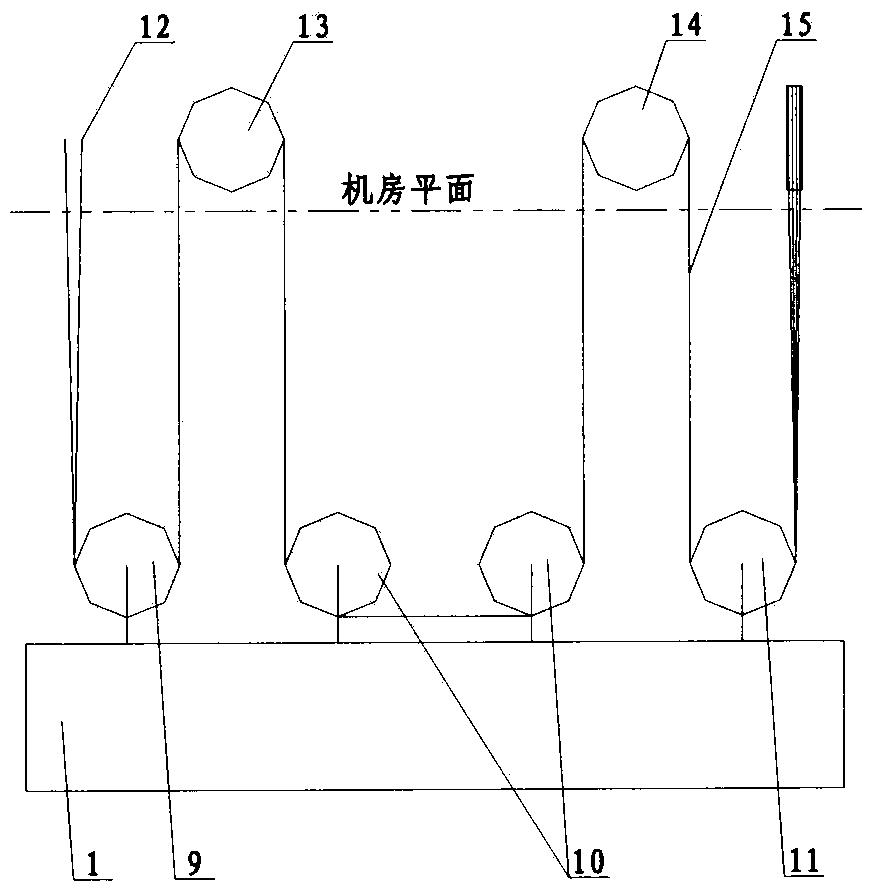

[0057] Embodiment 3: Large tonnage elevator 14:1 roping mode.

[0058] Embodiment 3 Explanation of reference numerals:

[0059]1-car, 2-fourth car top sheave assembly, 3-fifth car top sheave assembly, 4-sixth car top sheave assembly, 5-seventh car top sheave assembly, 6-A-share traction Leading rope head device, 7-side fixed pulley assembly of the third car, 8-side fixed pulley assembly of the fourth car, 9-side fixed pulley assembly of the fifth car, 10-A-share traction rope, 11-eighth Car top sheave assembly, 12-Ninth car top sheave assembly, 13-Tenth car top sheave assembly, 14-Eleventh car top sheave assembly, 15-B traction rope head device, 16-No. Sixth car side fixed pulley assembly, 17-seventh car side fixed pulley assembly, 18-eighth car side fixed pulley assembly, 19-B strand traction rope, 20-first car top sheave assembly, 21- Second car top sheave assembly, 22-third car top sheave assembly, 23-traction machine, 24-first car side fixed sheave assembly, 25-second ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com