Orbital hand tool apparatus for drilling

A technology of manual tools and tools, which is applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc., can solve the problems of not providing, cutting tools, bending moments, etc., to reduce the amount of deflection, reduce the The effect of tool length and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

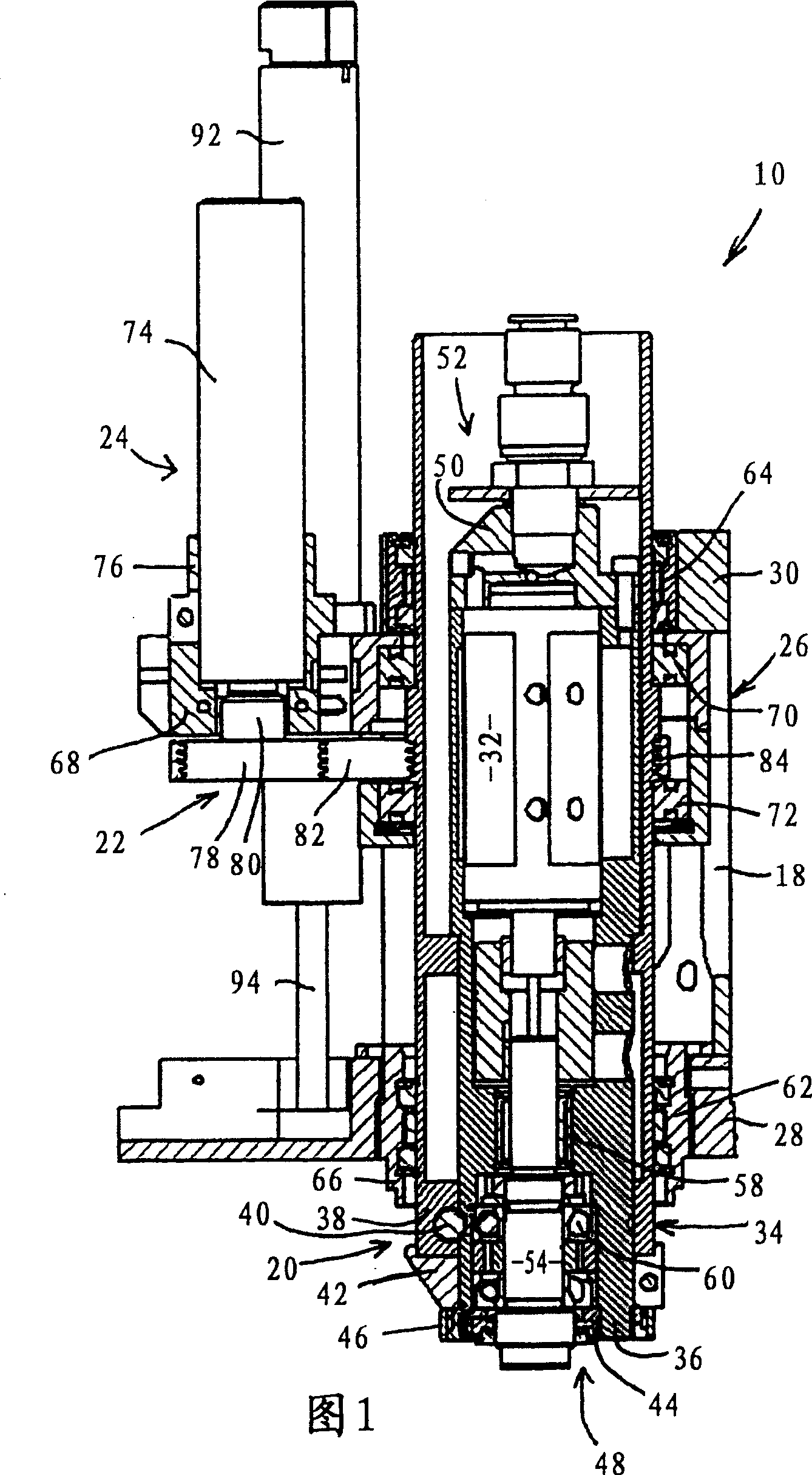

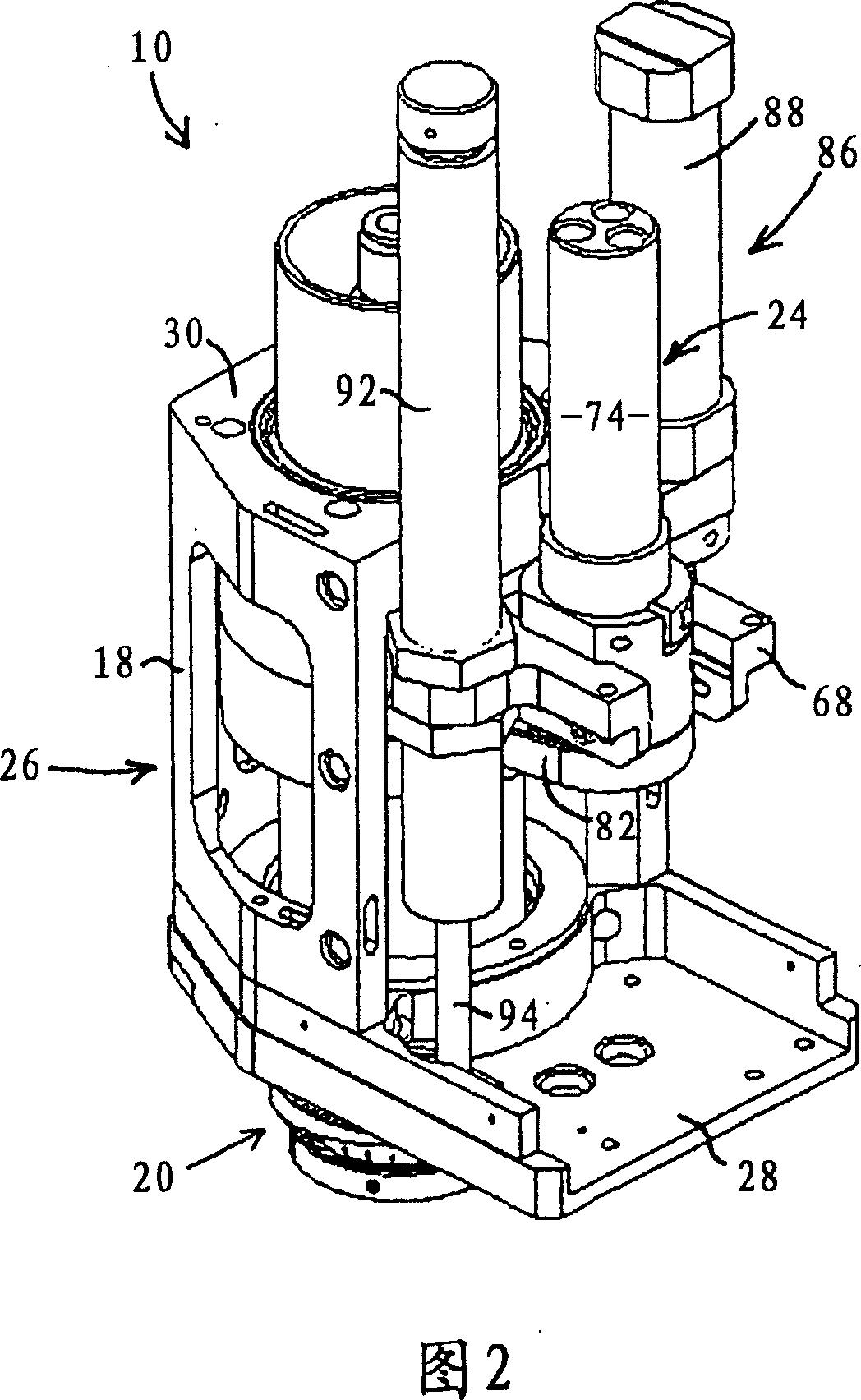

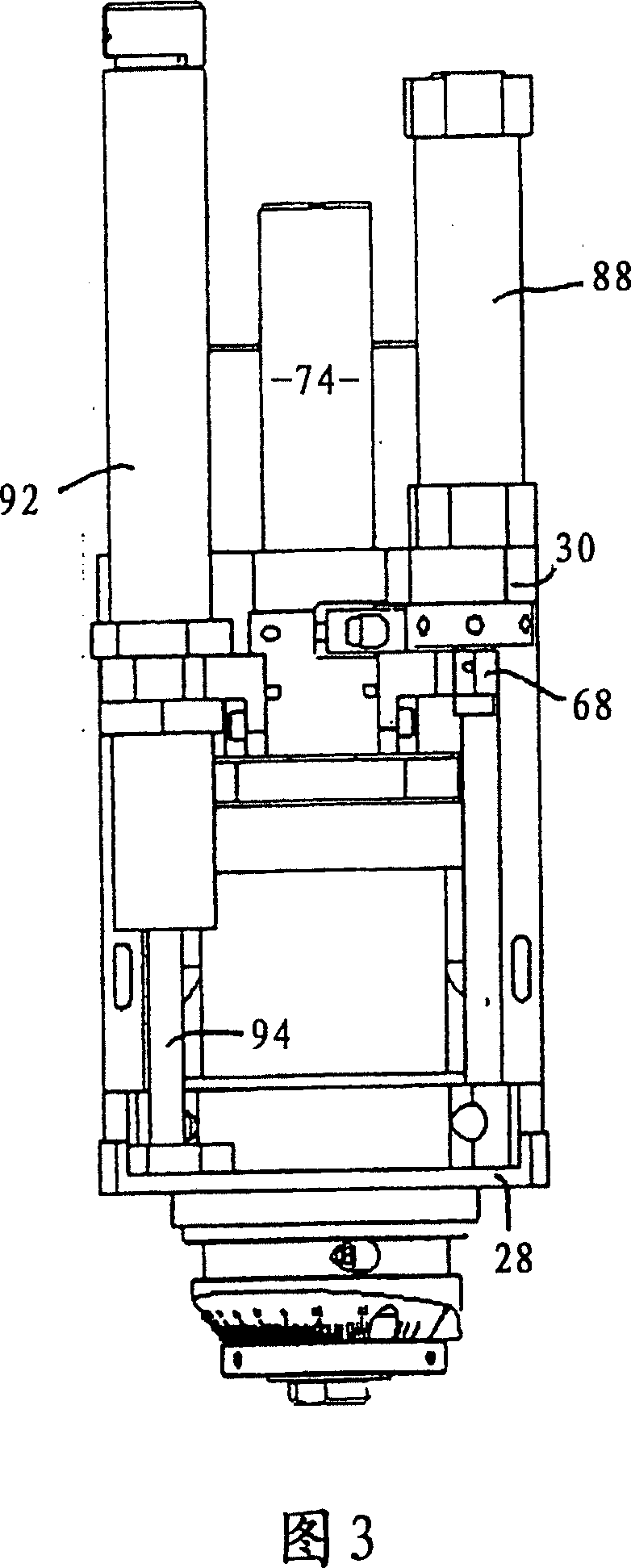

[0025] Referring now to the drawings, a hand tool arrangement in the form of a portable pneumatic orbital drill 10 is shown. The drill 10 includes a shaft member 20 and an eccentric rotation mechanism 22 provided with an orbital drive unit 24 secured to a frame or housing 26 of the drill 10 . The housing 26 includes a bottom panel 28 and a top panel 30 joined together by a wall member 18 . The spindle assembly 20 includes a spindle motor 32 and a radial offset mechanism 34 .

[0026]The radial deflection mechanism 34 generally comprises, in a substantially known manner, an internal bushing 36 in which the shaft part 20 is rotatably mounted. The shaft motor 32 is rotatably supported in an eccentric cylindrical hole provided on an inner sleeve 36 . The eccentric hole has a longitudinal central axis which is parallel to the longitudinal central axis of the sleeve 36 and offset by a certain distance in the radial direction relative to the longitudinal central axis of the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com