Gear shaft quenching work fixture

A tooling fixture and gear shaft technology, which is applied in the field of quenching tooling fixtures for active cylindrical gear shafts, can solve problems such as easy bending deformation, lack of precision, large deformation, etc., and achieve the effects of eliminating bending deformation, ensuring uniformity, and improving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

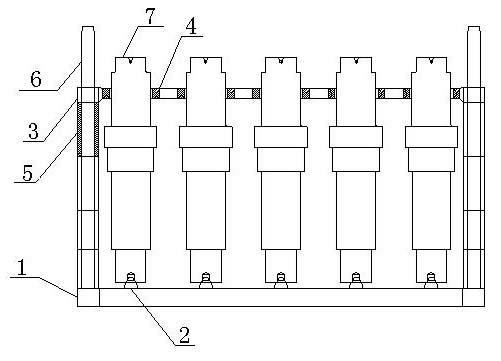

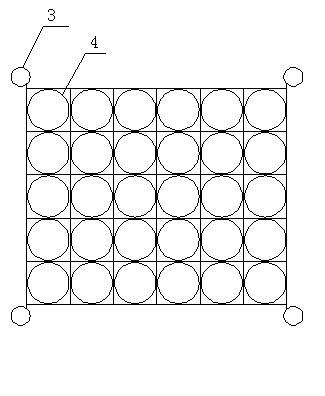

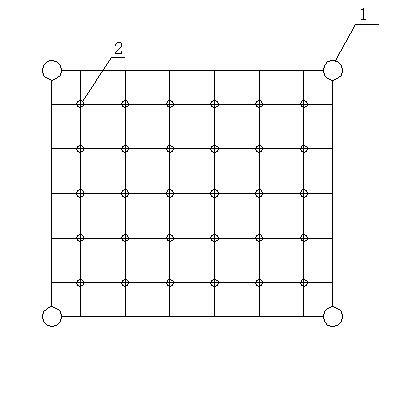

[0010] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a gear shaft quenching fixture, which includes a lower tray positioning sleeve 1 and an upper tray positioning sleeve 3, both of which are arranged in parallel and are movably installed on the vertical rod group 6, and the vertical rod group 6 is provided with a spacer 5, the spacer 5 is located between the positioning sleeve 3 of the upper feeding tray and the positioning sleeve 1 of the lower feeding tray, and is flexibly connected with the positioning sleeve 3 of the upper feeding tray. By adjusting the spacing sleeve 5, the positioning of the upper feeding tray can be lifted Cover 3, the vertical rod group 6 is made up of four vertical rods, and the four vertical rods are respectively located around the lower tray positioning sleeve 1 and the upper feeding tray positioning sleeve 3. One or more lower tray positioning thimbles 2 are provided on the lower tray positioning sleeve 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com