Blackening furnace

A furnace cover and furnace wall technology, which is applied in the field of blackening furnaces, can solve the problems of inability to increase the pressure of the furnace cavity, uneven thickness, and small thickness of the blackening layer, so as to achieve a convenient and fast opening process, good sealing effect and ideal sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

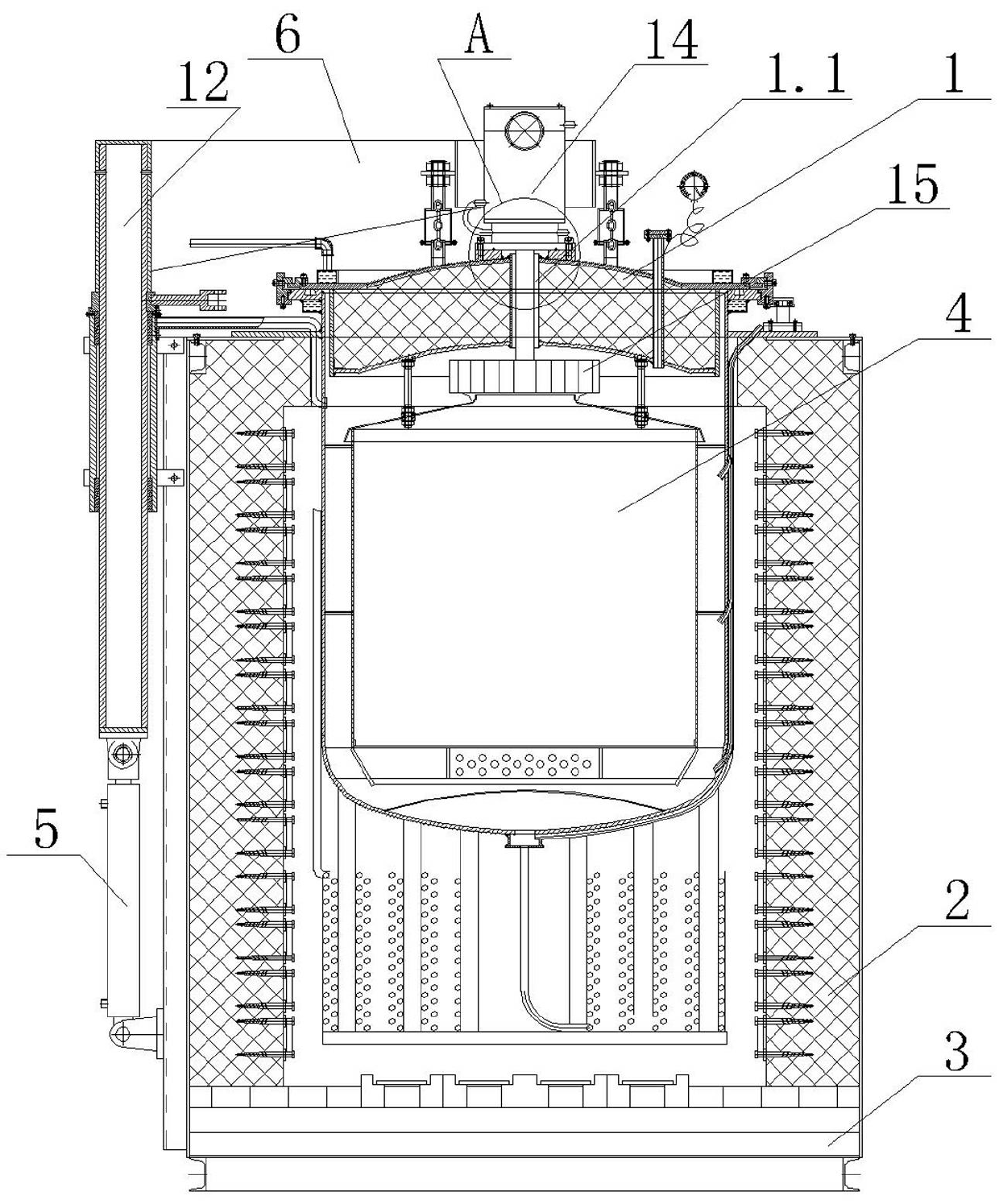

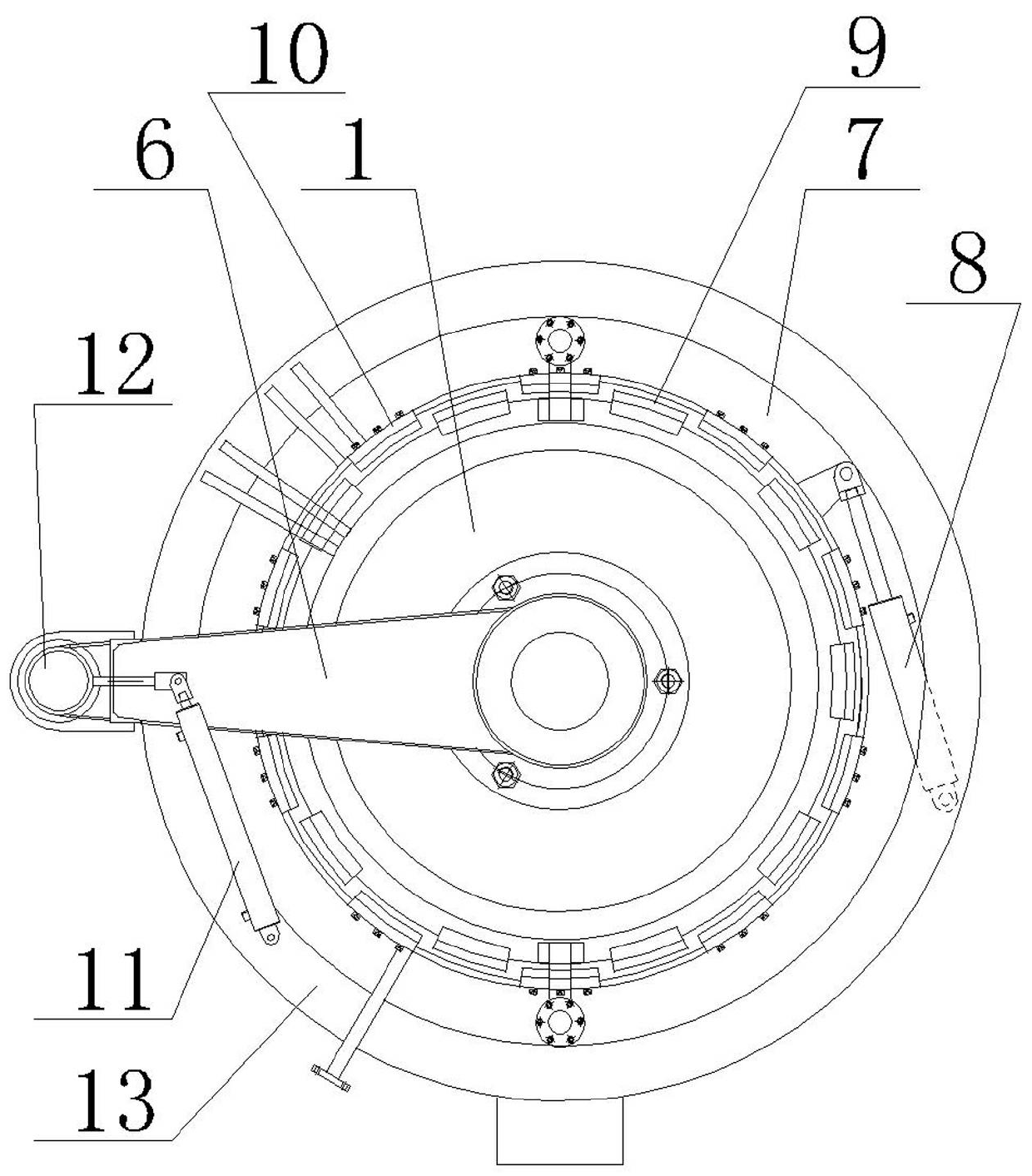

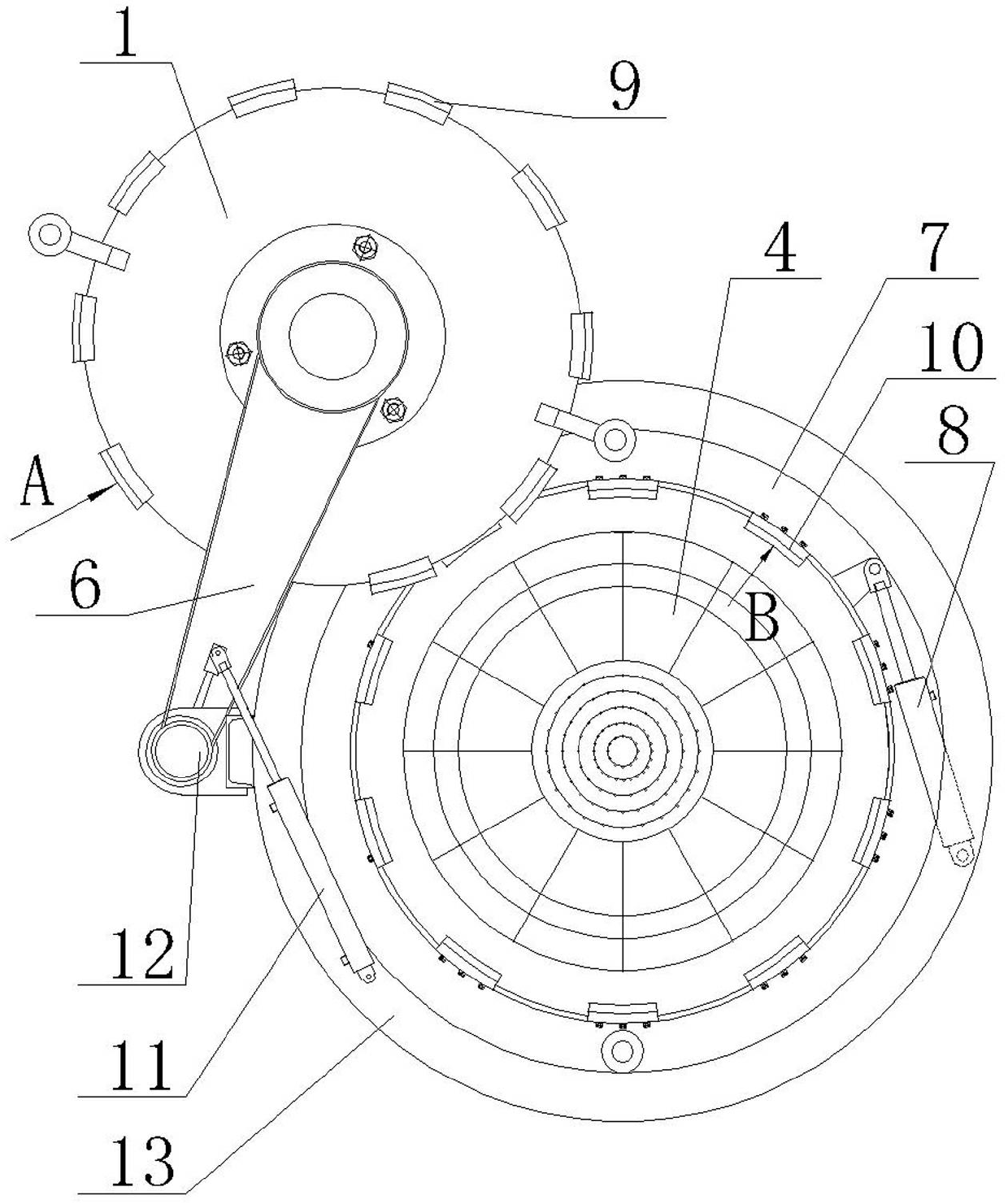

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 Shown, blackening furnace of the present invention, it comprises furnace cover 1, furnace wall 2, base 3, lifting cylinder 5, rocking arm 6, the 3rd cylinder 11, motor 14 and wind wheel 15. The furnace cover 1, the furnace wall 2 and the base 3 surround a synthetic furnace chamber 4. There is a through hole 1.1 through the furnace cover 1, and the output shaft 14.1 of the motor 14 is fixed to the wind wheel 15 in the furnace chamber 4 through the through hole 1.1 of the furnace cover 1. The lower end of the shell of the motor 14 is a flange end 14.2, the top of the furnace cover 1 is fixed with a flange 1.2, the flange end 14.2 of the motor 14 is fixed to the flange 1.2 of the furnace cover 1, and the flange end 14.2 of the motor 14 A sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com