Construction method for immersed tube type underground continuous wall without compacting

A construction method and tubular technology, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of lack of guarantee of concrete quality, large amount of engineering, long construction period, etc., and achieve the elimination of soil squeezing effect, high quality of concrete, The effect of fewer construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

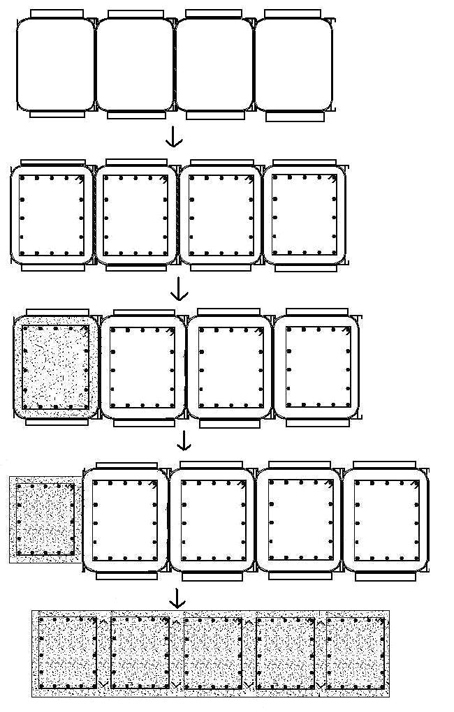

[0025] The construction method of the immersed tube type non-crowding underground diaphragm wall, the construction steps are as follows:

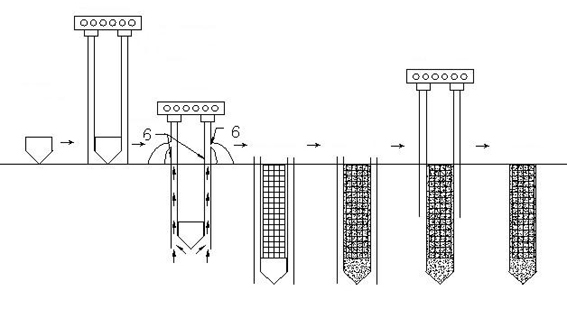

[0026] 1) Place the solid concrete pile shoe 7 on the designated pile position;

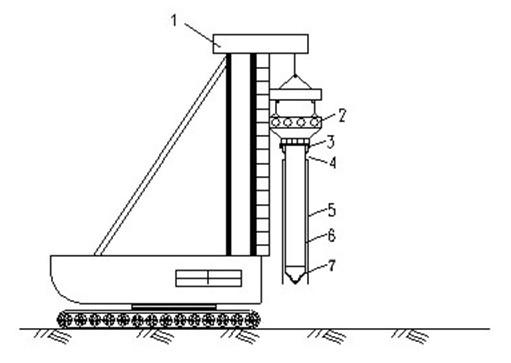

[0027] 2) Use the pile driver equipment 1 to lift the rectangular pipe sinker 5, and set the rectangular pipe sinker 5 with the soil discharge pipes 6 on both sides on the solid concrete pile shoe 7;

[0028] 3) Hit the holder 3 on the top of the rectangular pipe sinker 5 with a high-frequency hydraulic vibrating hammer 2, vibrate in turn into a group of four rectangular pipe sinkers that are adjacent to each other, and the soil passes through the discharge pipes on both sides of the rectangular pipe sinker 6 The bottom port enters the soil discharge pipe 6, and is discharged to the ground from the mud outlet 4 on the top of the soil discharge pipe 6;

[0029] 4) Place a reinforcement cage in the rectangular immersed tube;

[0030] 5) Pour concrete into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com