Wastewater Treatment Method Using Membrane Separation Activated Sludge Process

A technology of activated sludge method and wastewater treatment, which is applied in water/sludge/sewage treatment, sludge treatment, biological water/sewage treatment, etc. It can solve the problems of deterioration of filtration, prolongation of chemical liquid impregnation time, and complexity. Achieving the effect of reducing the risk of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

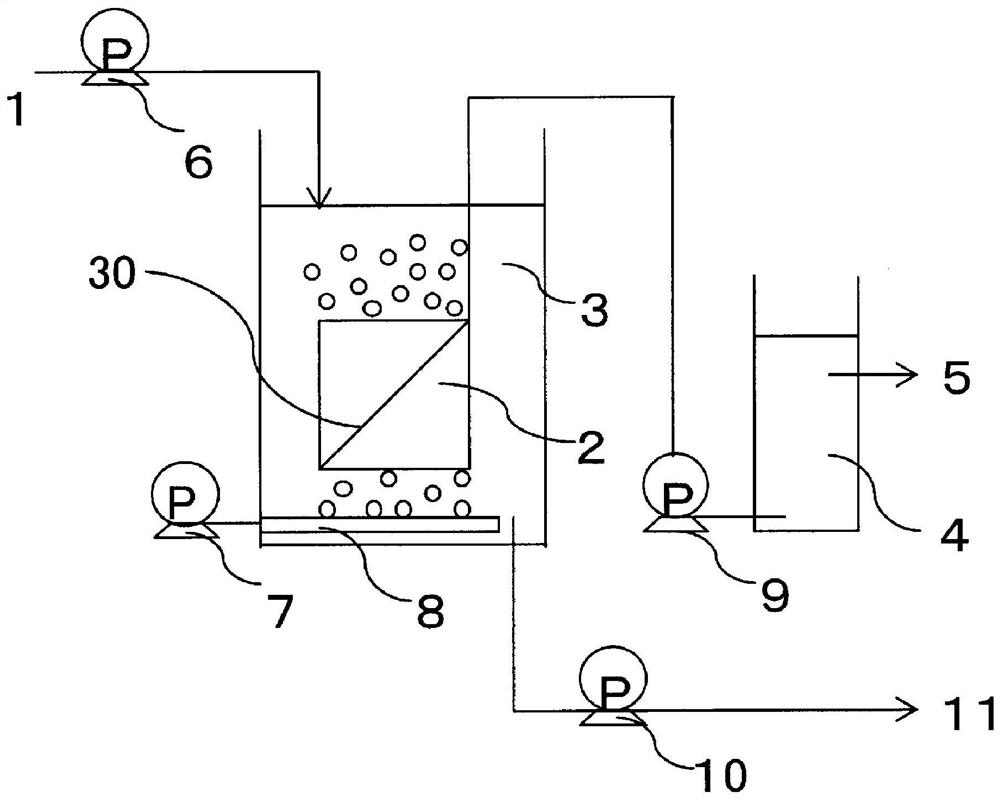

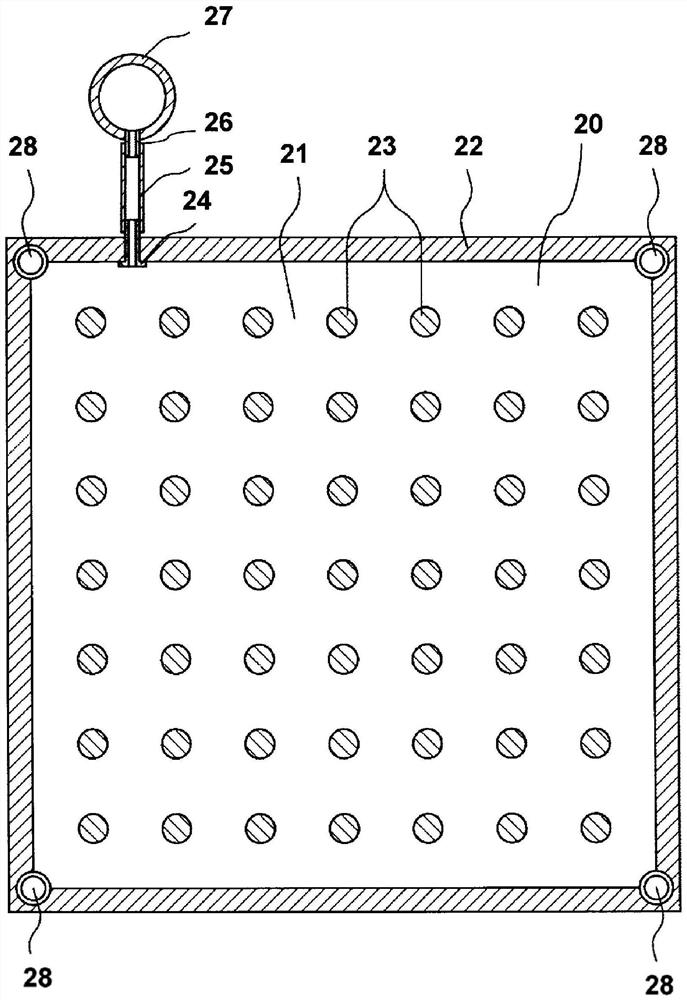

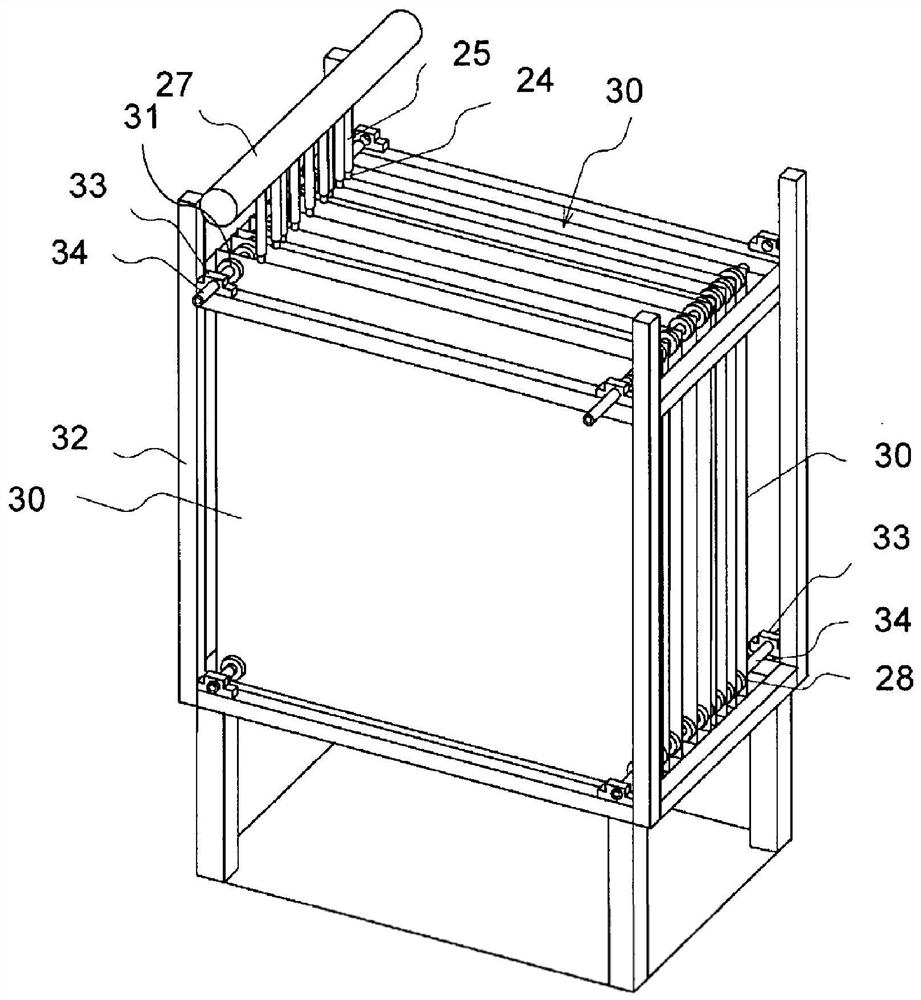

[0105] In an agricultural wastewater treatment facility, 50 units are installed at intervals of 7.5 mm between adjacent flat membrane elements using a gap-maintaining material made of ethylene-propylene rubber with a thickness of 7.5 mm. figure 2 The flexible flat membrane element shown (width 500mm×height 1000mm, thickness 3mm, effective membrane area is 1m 2 , polyvinylidene fluoride) impregnated membrane separation unit ( image 3 ),exist figure 1 The membrane separation activated sludge device shown (width 1.5m, depth 1m, height 3m, tank volume 4.5m 3 ) set a unit in the slot. A diffuser 8 for air supply was installed below the submerged membrane separation unit, and air was supplied to the diffuser 8 by the air supply device 7 at 330 NL / min / module. Using one unit of this device, the agricultural wastewater is used as the water to be treated, and the operation is performed for about 3 months while supplying air while filtering. Regarding the filtration flow rate, the ...

Embodiment 2

[0113] In the waste water treatment plant of polymer resin manufacturing engineering, 50 flexible membrane elements (width 500mm× Height 1000mm, thickness 3mm, effective membrane area 1m 2 , polyvinylidene fluoride) impregnated membrane separation unit ( image 3 ),exist figure 1 The membrane separation activated sludge device shown (width 1.5m, depth 1m, height 3m, tank volume 4.5m 3 ) set a unit in the slot. A diffuser 8 for air supply was installed below the submerged membrane separation unit, and air was supplied to the diffuser 8 by the air supply device 7 at 350 NL / min / module. Using one unit of this device, the waste water from the polymer resin manufacturing process was used as the water to be treated, and it was operated for about 3 months while supplying air while filtering. Regarding the filtration flow rate, the sludge is collected in advance, and it is set to 0.5m based on the results of the preliminary test 3 / m 2 / d.

[0114] The filtration pressure differ...

Embodiment 3

[0123]In the same polymer resin-based manufacturing engineering wastewater treatment plant as in Example 2, at a different time period (when the water temperature is low in winter) from the period of Example 2 (when the water temperature is high in summer), a machine with an impregnated water tank installed in the tank is used. The membrane separation activated sludge device of type membrane separation unit (device structure is identical with embodiment 2), carries out filtration operation. Here, in order to improve the filterability of the sludge, a cationic polymer coagulant was added based on the conditions determined by the preliminary test. 3 / m 2 / d, air supply 350NL / min / module) for operation.

[0124] The filtration pressure difference P1 at the initial stage of operation is 5kPa. After continuing the operation of filtering while supplying air for 3 months, the filter pressure difference reached 15 kPa set as the predetermined value P2, so cleaning was performed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com