Shearing synchronous oil circuit for flash welding machine

A flash welding machine and oil circuit technology, applied in mechanical equipment, welding equipment, resistance welding equipment, etc., can solve the problems of increasing the movement deviation of the two-push convex oil cylinder, affecting the quality of the welded joint, and damaging the rail base metal, etc. Low mass, cost and complexity, light weight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

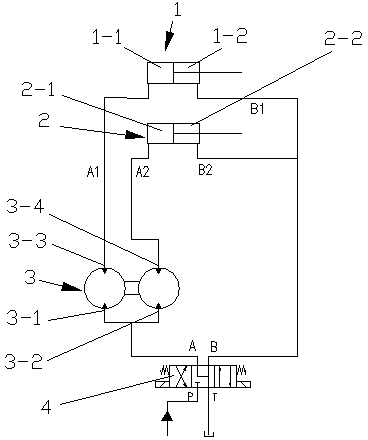

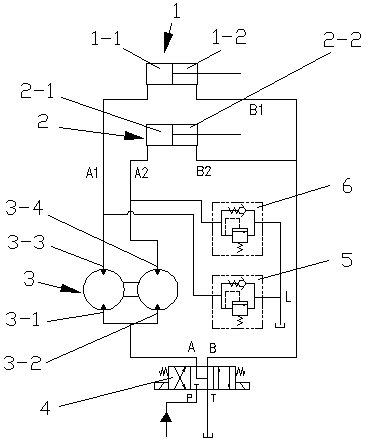

[0011] Such as figure 1 As shown, the first embodiment of the present invention, a flash welder push-protrusion synchronous oil circuit, includes a first push-protrusion cylinder 1, a second push-protrusion cylinder 2 and a three-position four-way reversing valve 4, the first One push convex oil cylinder 1, the second push convex oil cylinder 2 all have first cavity 1-1, 2-1 and second cavity 1-2, 2-2, and described three-position four-way reversing valve 4 has first oil Port P, the second oil port A, the third oil port T and the fourth oil port B, the first oil port P of the three-position four-way reversing valve 4 is connected to the oil inlet circuit, and the third oil port T is connected to the return oil The road also includes a synchronous motor 3, the first inlet 3-1 and the second inlet 3-2 at one end of the synchronous motor 3 are connected with the second oil port A of the three-position four-way reversing valve 4, and the synchronous motor 3 is another The first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com