Electromagnetic brake with buffer for noise reduction

An electromagnetic brake and buffer technology, applied in the direction of brake actuator, gear transmission mechanism, mechanical equipment, etc., can solve the problems of large starting clearance, small buffer force, long buffer stroke, etc., to increase the rigidity of the system and increase the buffer. force, the effect of reducing motion noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

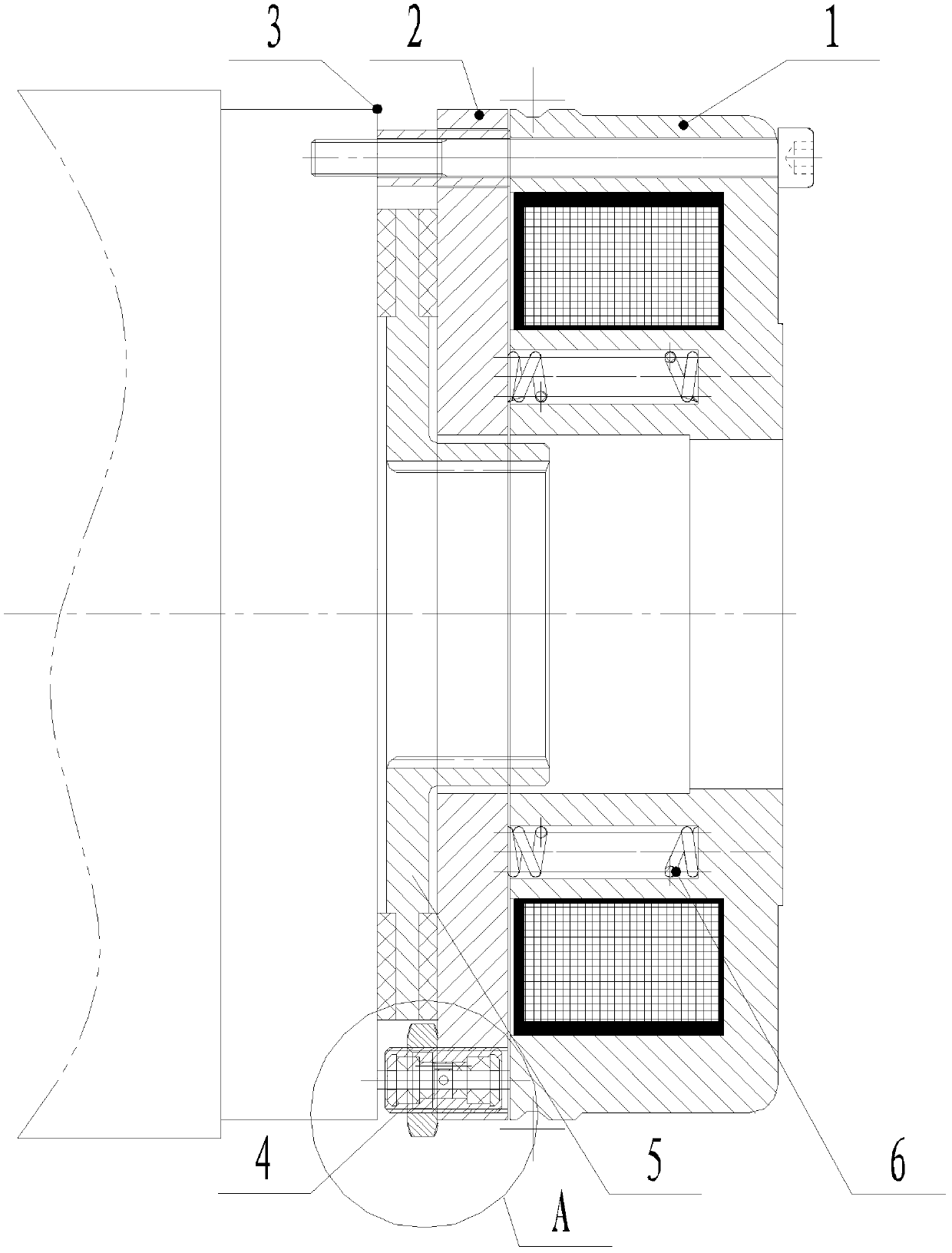

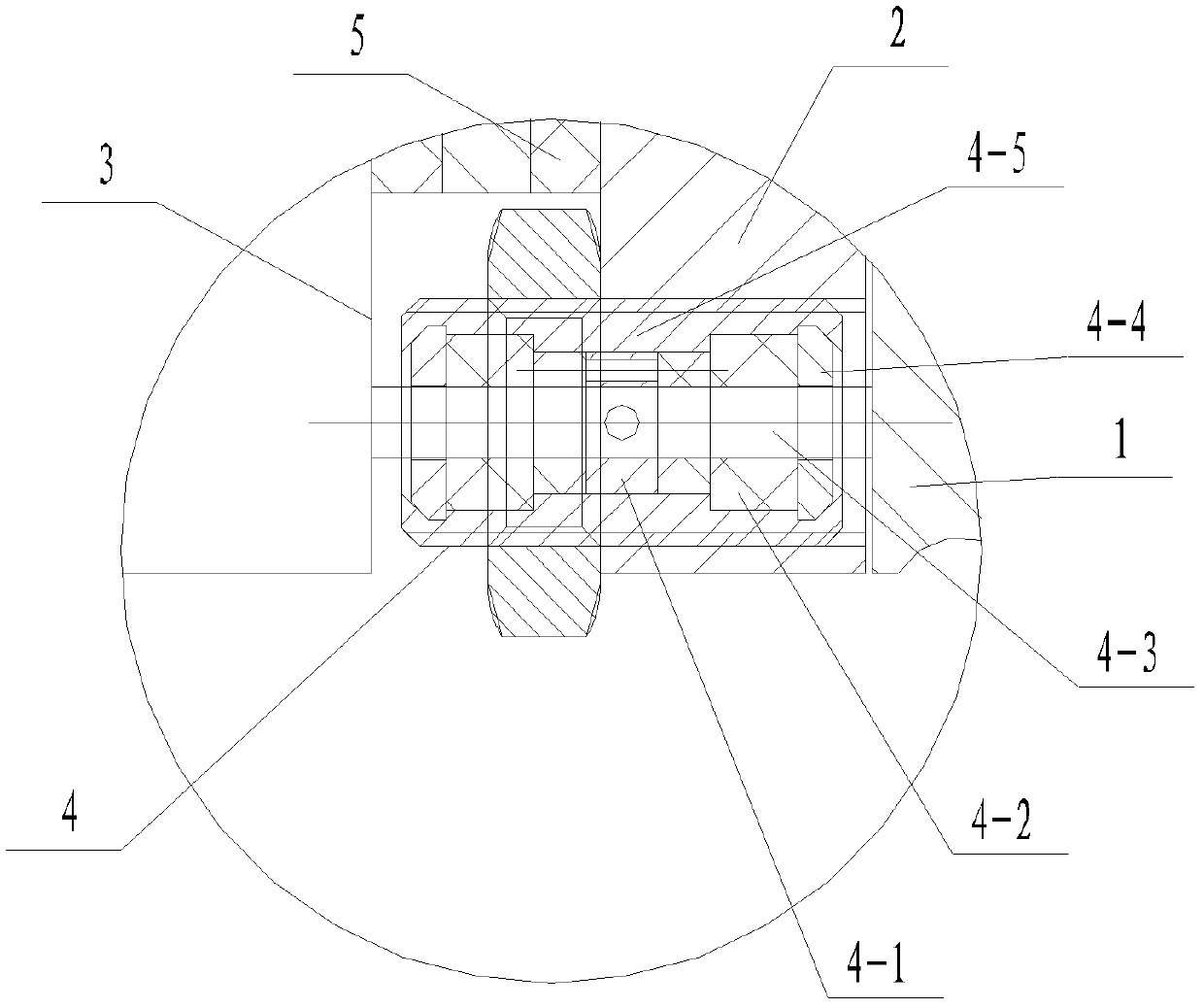

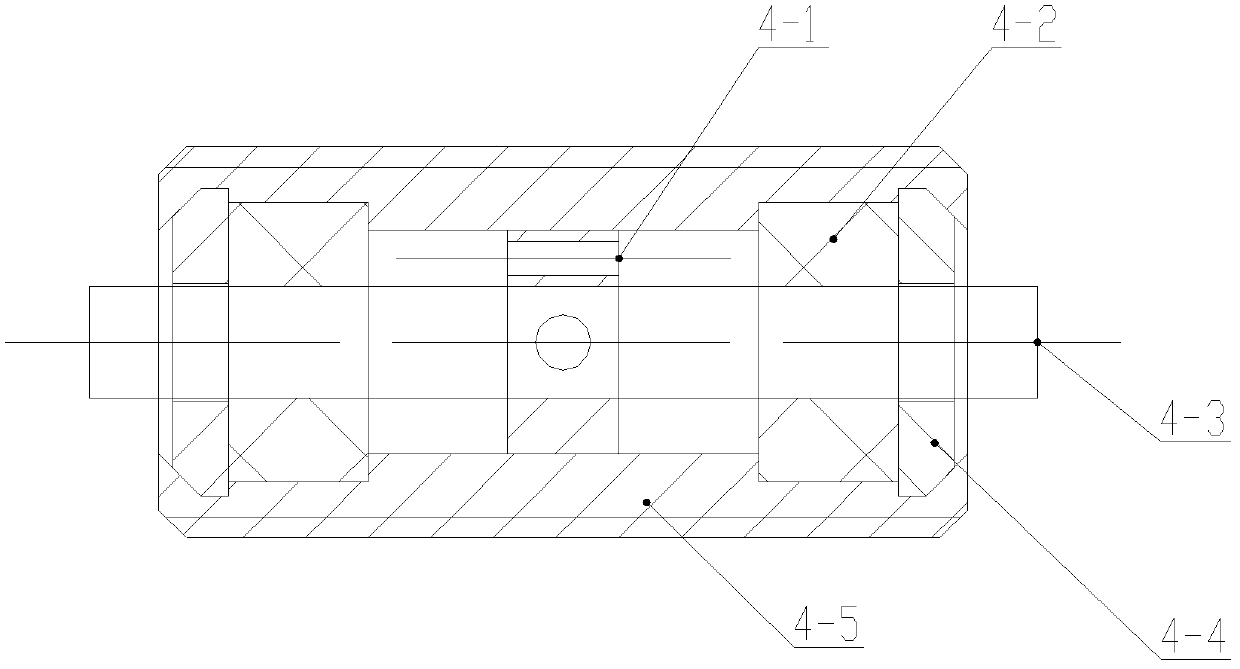

[0016] see Figure 1 ~ Figure 3 , an electromagnetic brake with a buffer for noise reduction, the brake is fixed on the installation surface 3, including a stator yoke 1 fixed on the installation surface 3, a coil is embedded in the stator yoke 1, and the stator yoke 1 is provided with The armature 2 that is movably connected with it has a friction disc 5 installed on the armature 2, and the friction disc 5 is adjacent to the installation surface 3; a plurality of springs 6 are clamped between the stator yoke 1 and the armature 2; Buffer 4; the buffer 4 is a piston structure, the piston 4-1 is installed in the sealed cylinder 4-5 filled with elastic cement medium, the cylinder 4-5 is fixed on the armature 2, and the piston 4-1 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com