Vibration reduction buffering method and system for offshore steel girder hoisting

A cushioning system and cushioning method technology, applied in transportation and packaging, load suspension components, springs/shock absorbers, etc., can solve the problems of frequent lateral vibration, single vibration direction, large amplitude change, etc., to eliminate fatigue, The effect of large buffer energy and balanced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

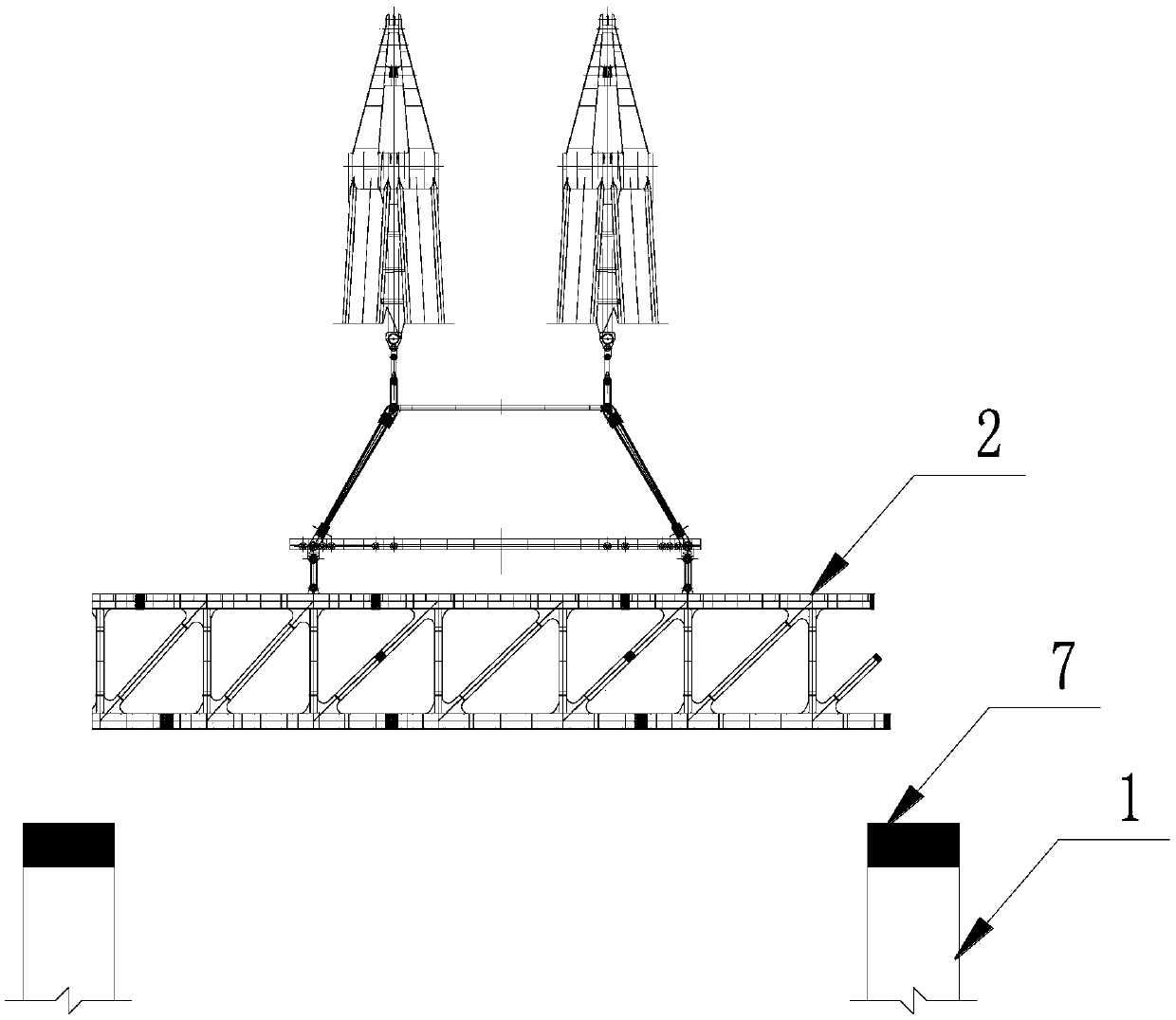

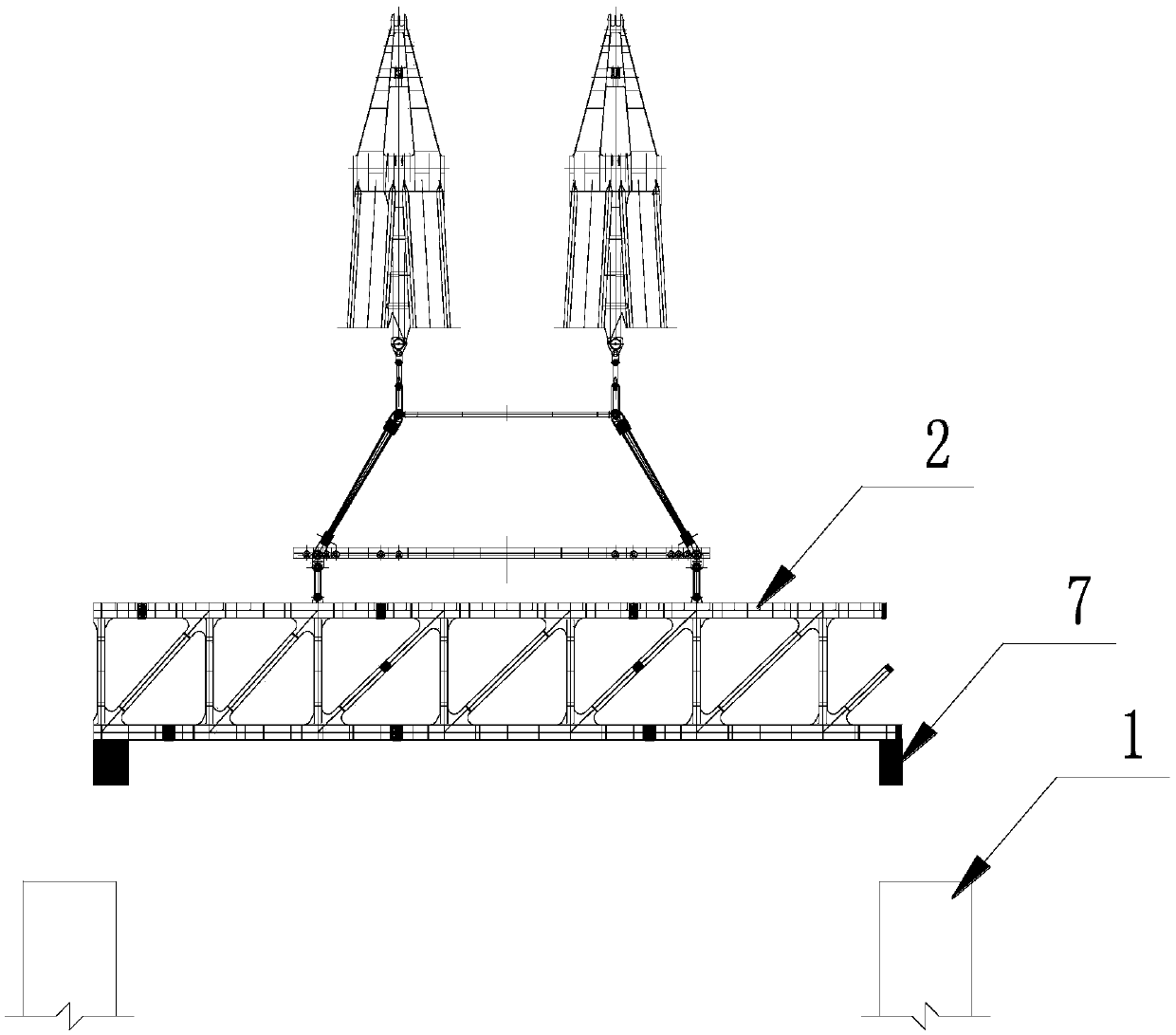

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

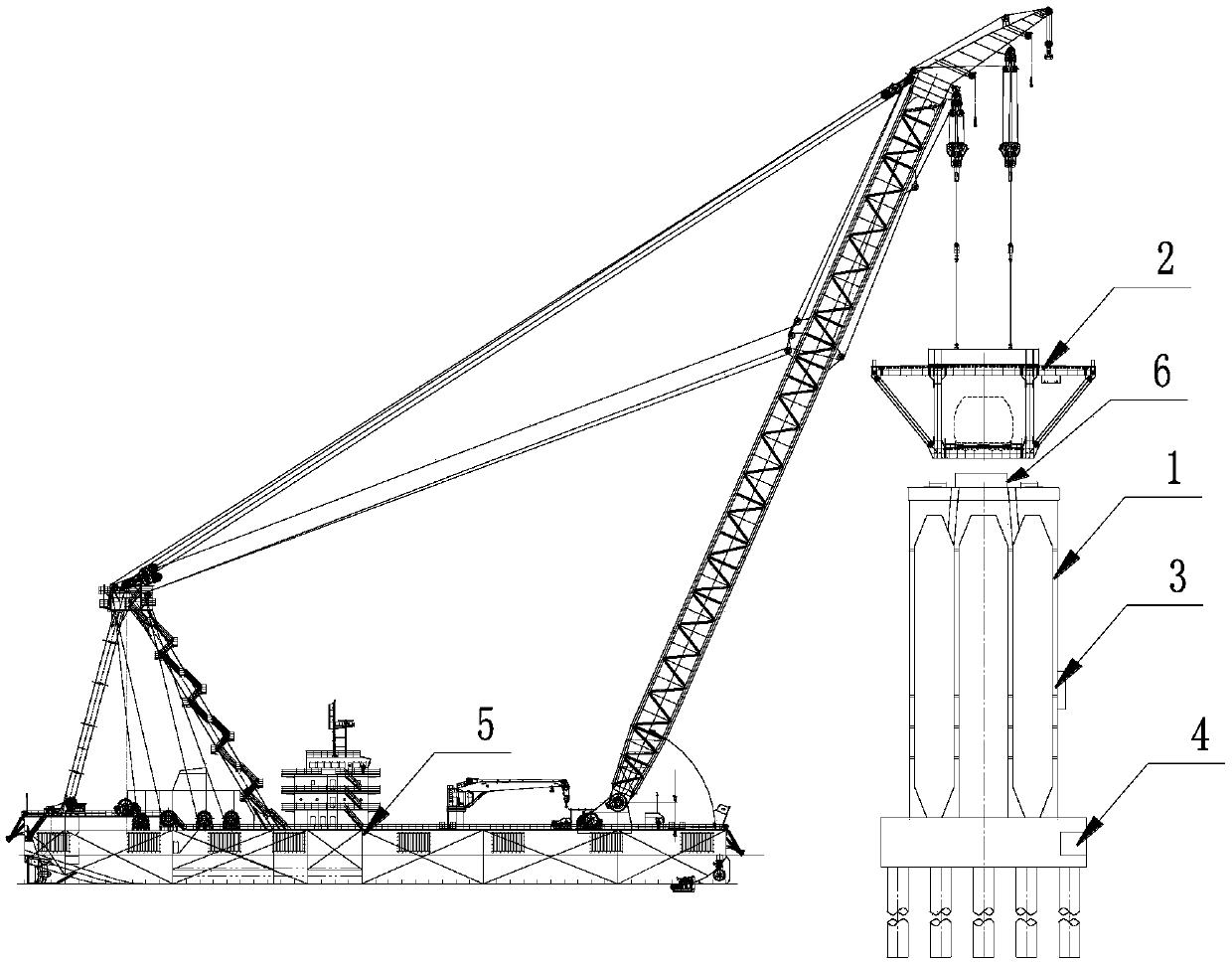

[0036] see Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a vibration damping and buffering system for hoisting steel girders at sea, which is arranged on the pier 1 of the steel girder 2 to be hoisted, including:

[0037] The automatic identification system, which is arranged on the pier 1, includes a wind wave detection component and a vibration test component, the wind wave detection component includes an anemometer 3 and a wave meter 4, and the vibration test component includes a hull attitude meter 5 and an inclinometer 6;

[0038] The vibration damping system is arranged on the bridge pier 1 or the steel girder 2, and the vibration damping system includes a buffer component for realizing a specific buffer function. In specific operations, different types of buffer components can be set according to actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com