Anti-scouring valve sealing structure

A valve sealing and anti-scouring technology, which is applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of sealing ring damage, sealing ring can not resist scouring, valve sealing failure, etc., to achieve reliable sealing performance and reliable valve operation , Strong anti-scouring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

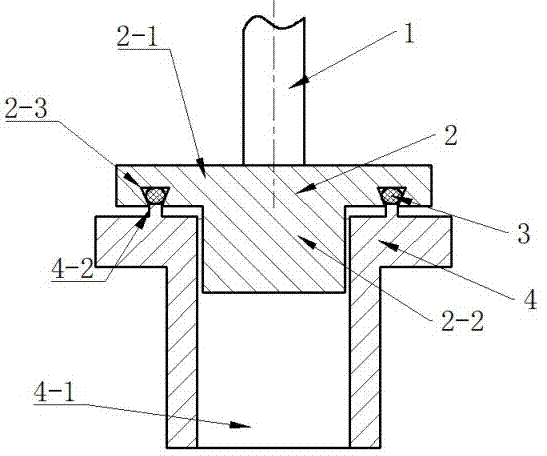

[0025] An anti-scouring valve sealing structure according to the present invention comprises: a valve stem (1), a valve core (2), and a valve body (4). The valve stem (1) is fixedly connected with the valve core (2). It is characterized in that: the upper end of the spool (2) is the spool end cover (2-1), the lower end is the spool cylinder (2-2), and the lower surface of the spool end cover (2-1) is designed with a notch (2-1). -3), the notch (2-3) is equipped with a sealing ring (3); the upper surface of the valve body (4) is designed with a sealing seat (4-2), and the sealing seat (4-2) is connected with the end cover of the valve core The notch (2-3) of (2-1) fits; the center of the valve body (4) is designed with a flow channel (4-1), and the flow channel (4-1) and the valve core cylinder (2-2) adopt clearance fit .

[0026] The working principle of this example: When the valve needs to release high-pressure gas, the valve stem (1) is lifted upward to drive the valve co...

Embodiment 2

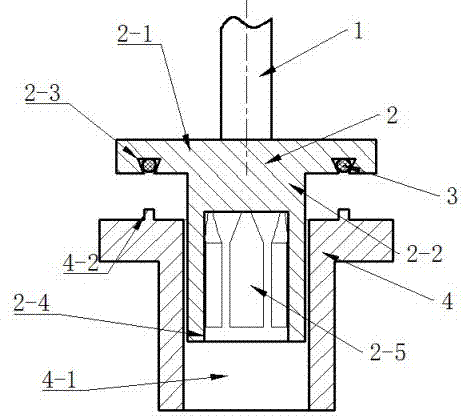

[0028] The spool cylinder (2-2) described in this example is provided with a blind hole (2-4), and a discharge port (2-5) is designed on the outer surface of the spool cylinder (2-2). (2-5) has a certain distance from the lower surface of the valve core end cover (2-1), and the discharge port (2-5) penetrates the blind hole (2-4).

[0029] The working principle of this example: When the valve needs to release high-pressure gas, the valve stem (1) is lifted upwards to drive the valve core (2) to move upward. When the sealing seat (4-2) and the sealing ring (3) are just separated, the valve core ( 2) The discharge port (2-5) on the top is below the upper surface of the valve body (4). Since the valve body (4) and the valve core cylinder (2-2) adopt a clearance fit, a small amount of high-pressure gas will flow from the valve Body (4) and the valve core cylinder (2-2) cooperate with the gap to flow out, but at this time the flow resistance coefficient of the gas is large, so the ...

Embodiment 3

[0031] The sealing seat (2-6) is designed on the valve core end cover (2-1) described in this example, and a notch (4-3) is designed on the upper surface of the valve body (4), and the rest are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com