Integrated blowdown apparatus of trailer operation bin with eleven high-pressure gas cylinders

A sewage device and high-pressure gas cylinder technology, applied in the direction of gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of joint air leakage, low impact resistance, and difficult manipulation of the handle of the balloon valve in and out of the operating compartment, etc. Achieve the effects of reducing installation stress, convenient disassembly and assembly, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

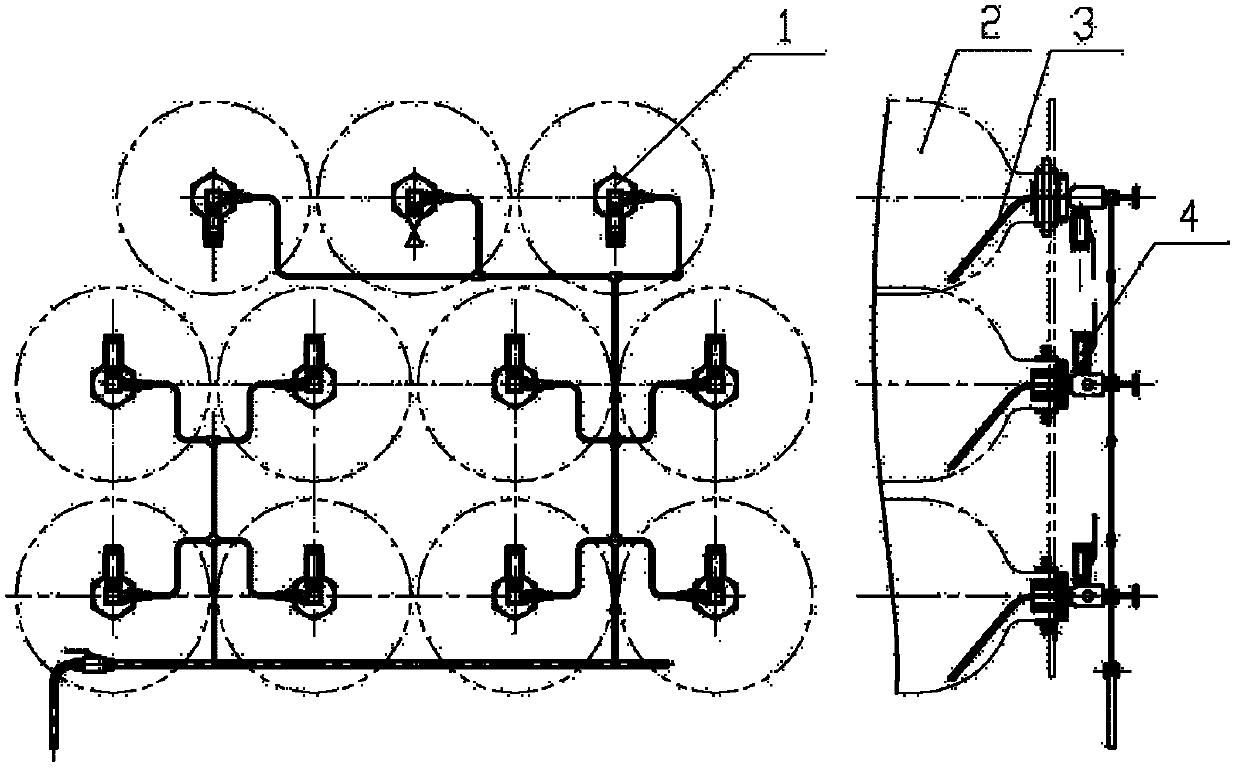

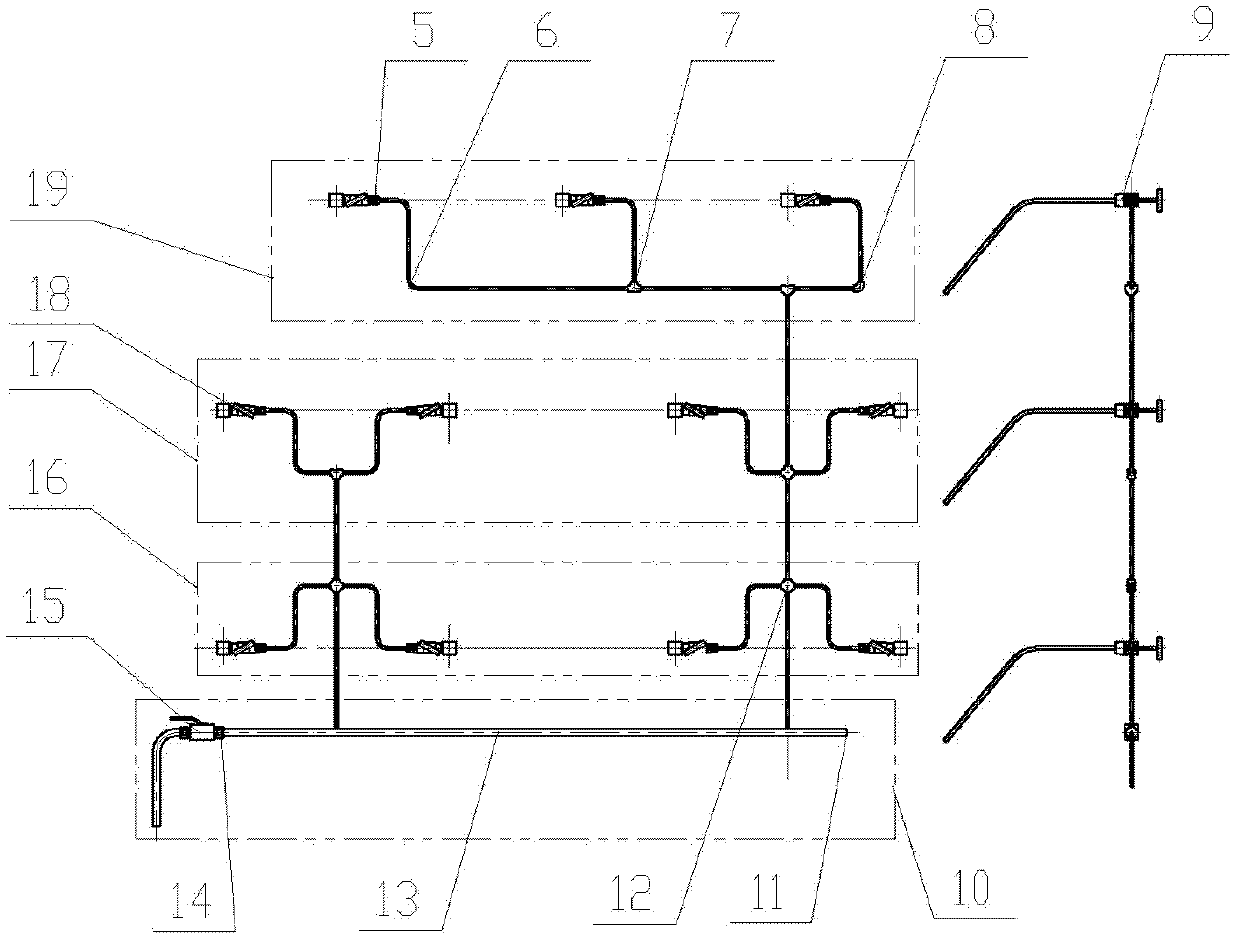

[0017] Figure 1 ~ Figure 3 It is a specific embodiment of the present invention.

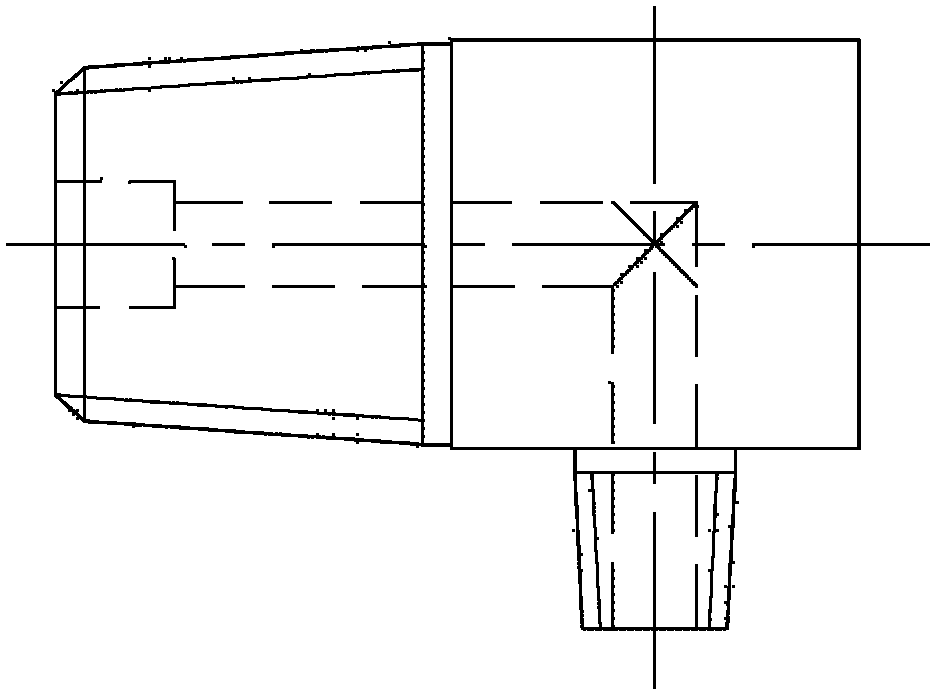

[0018] The present invention includes: external thread variable diameter elbow 9, internal sewage discharge pipe 3, integrated communication pipeline, sewage collection pipeline 10, eleven internal sewage discharge pipes 3 are connected to integrated communication pipeline through external thread variable diameter elbow 9, The integrated communication pipelines are combined and connected to the sewage collection pipeline 10, thereby completing the discharge of impurities during the use of the integrated sewage discharge device.

[0019] The integrated communication pipeline is the integration of the upper integrated communication pipeline 19 , the middle integrated communication pipeline 17 , and the lower integrated communication pipeline 16 .

[0020] The integrated communication pipeline is the integration of the upper integrated communication pipeline 19, the middle integrated communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com