Gripper for tension test

A tensile test and gripper technology, used in instruments, scientific instruments, measuring devices, etc., can solve the problem of difficulty in clamping the sample, and achieve the effect of improving the clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

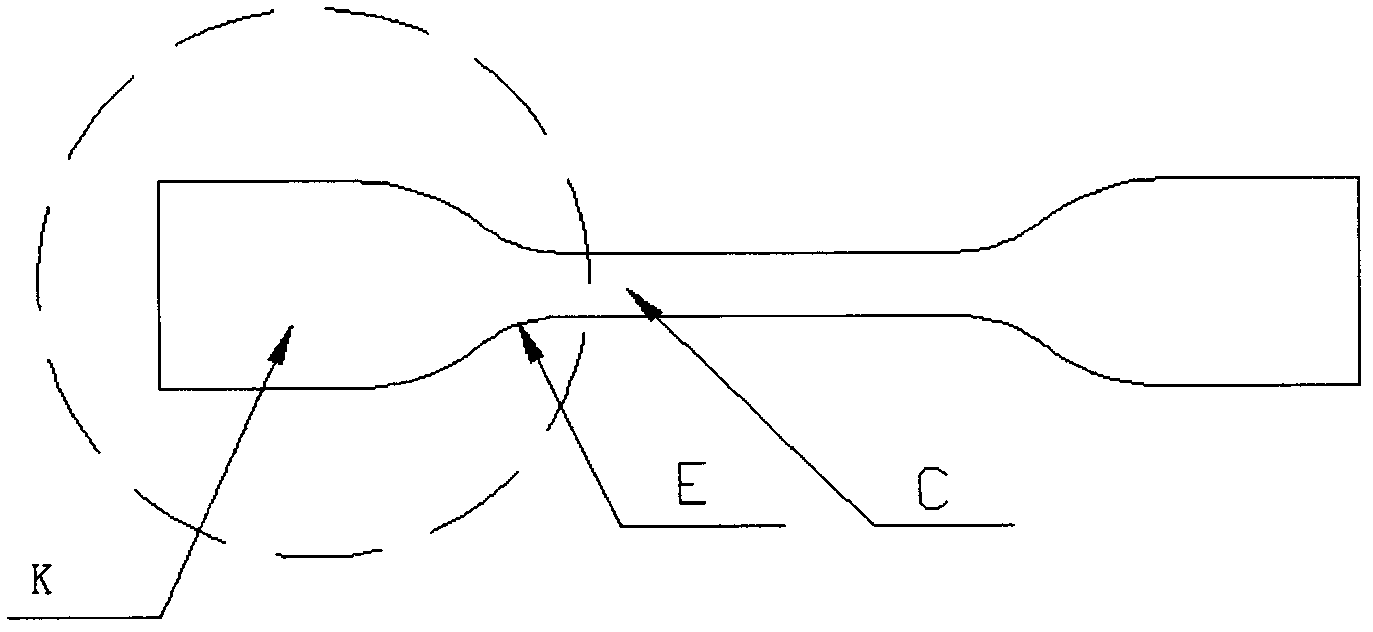

[0017] Refer to attached figure 1 , In the material tensile performance test, the shape of the sample is the standard dumbbell shape specified in GB / T528. The dumbbell-shaped standard specimen consists of two ends K, four outer transition edges E and a narrow parallel portion C.

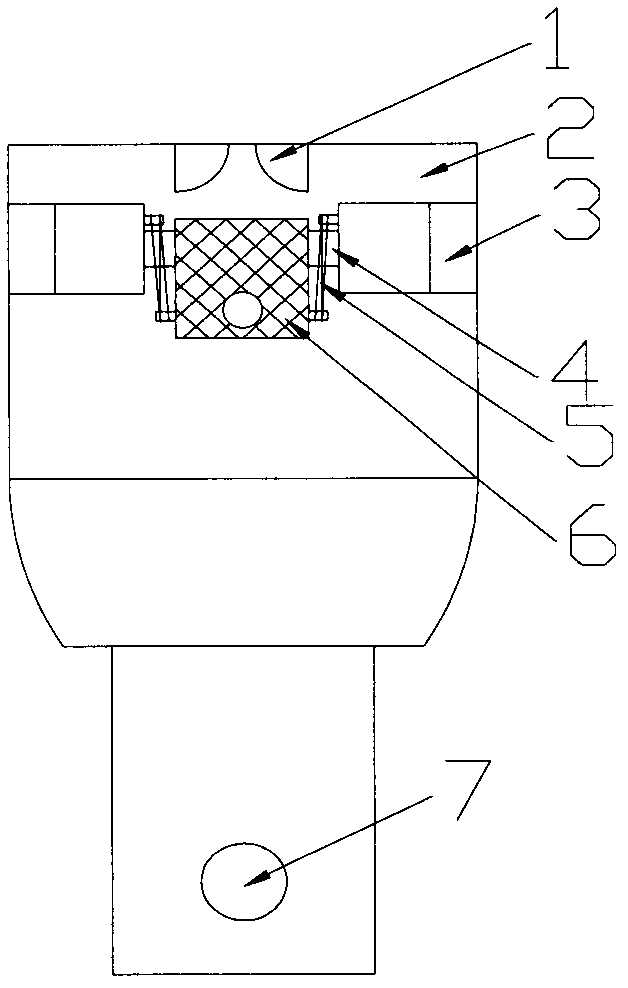

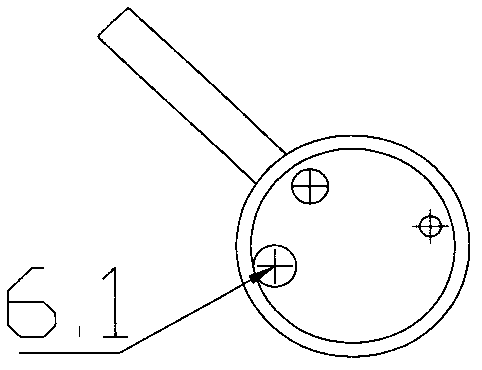

[0018] Refer to attached figure 2 , 3 Implement the invention. The clamping end of the clamp used in the tensile test can be processed into a stepped cylinder, and the end with a smaller diameter is a cylinder with a through hole 7 at the end, and the other end with a larger diameter is machined into a plane 2 with a milling machine. The cross section is semicircular; the mounting bracket 3 is fixed on the plane, and the spring automatic locking eccentric wheel 6 is installed through the bracket 3 . The spring automatic locking type eccentric wheel 6 can be processed by using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com