Liquid crystal display device and manufacturing method thereof

A technology of a liquid crystal display device and a manufacturing method, which is applied in the directions of optics, instruments, nonlinear optics, etc., can solve problems such as easy generation of moiré, halo effect, and large edge thickness of PI film, and achieve the effect of preventing moiré

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

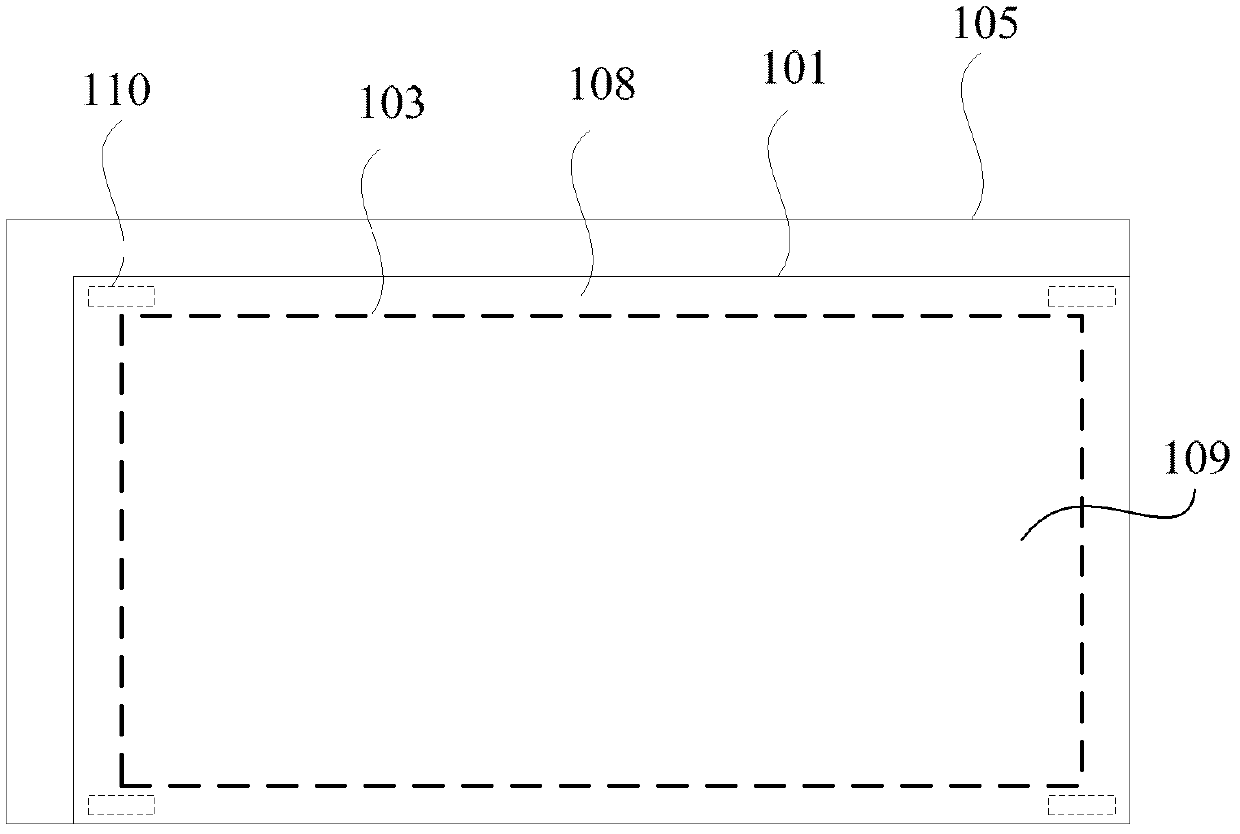

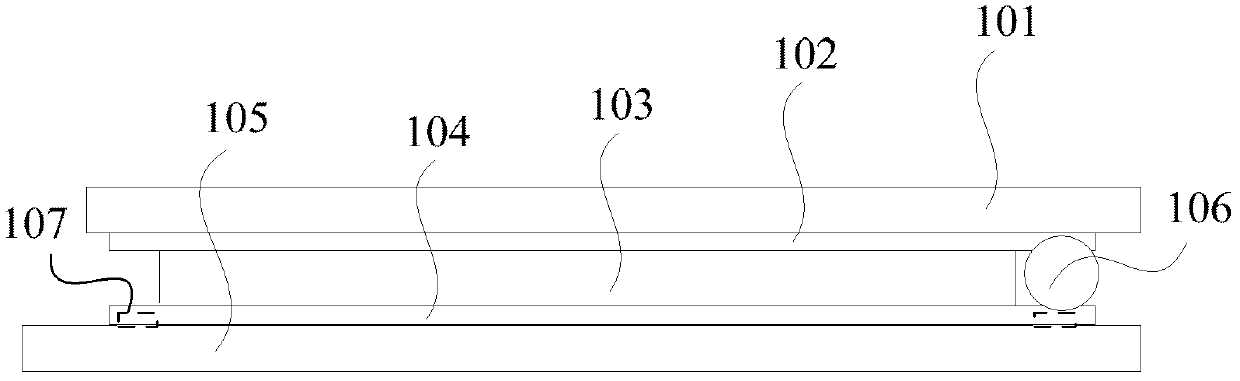

[0027] refer to figure 1 and figure 2 , figure 1 It is a side view of the first embodiment of the liquid crystal display device of the present invention. figure 2 yes figure 1 side view. In this embodiment, the liquid crystal display device includes a first substrate 101 , a sealant 103 , a second substrate 105 and a liquid crystal layer (not shown).

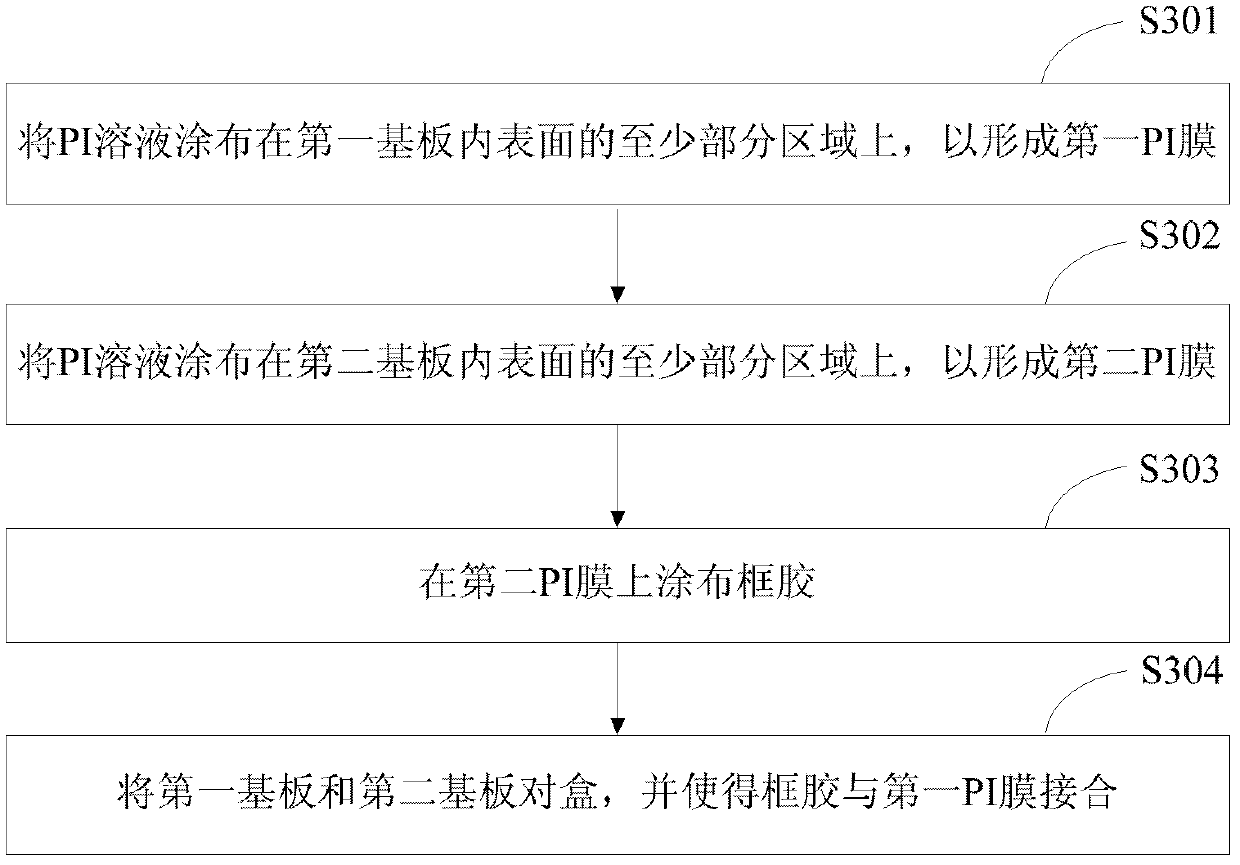

[0028] The inner surface of the first substrate 101 is provided with a first PI film 102 . A second PI film 104 is disposed on the inner surface of the second substrate 105 . Wherein, the first PI film 102 and the second PI film 104 are obtained by drying a PI solution with a solid content concentration lower than 7%. After drying, the thickness of the first PI film 102 and the second PI film 104 is 0.1 micron. In a preferred embodiment, the solid content concentration of the PI solution ranges fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com