Offshore buoyant cable

A technology of floating cables and floating components, which is applied in the field of power cables, can solve the problems of cable rotation, inability to meet transmission capacity and power supply mode at the same time, load bearing and floating performance at the same time, and achieve the effect of ensuring feasibility and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

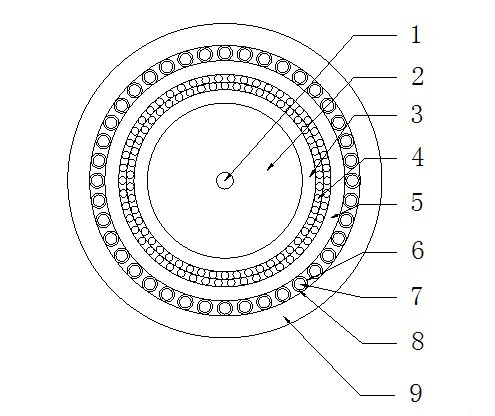

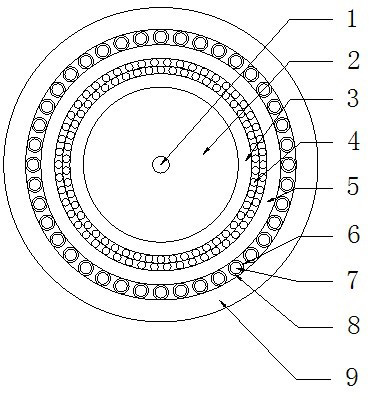

[0016] Such as figure 1 As shown, a floating offshore cable with a conductor structure according to the present invention includes a floating core connecting rope 1 in the center of the cable, and a floating element 2 is wrapped around it. The floating element 2 is provided with a sealing layer 3, and the main conductor 4 is twisted combined on the sealing layer 3, covering the inner sheath 5 on the main conductor 4, and winding the guiding body 6 on the inner sheath 5; the guiding body 6 is composed of several conductors 7 and an insulating layer 8 coated on the conductor 7; The guiding body 6 is extruded with a protective layer 9 .

[0017] The present invention provides a structural form and implementation method of a floating cable conductor on the sea. The above description is only a preferred implementation method of the present invention. It should be pointed out that for those skilled in the art, the Under the premise, some improvements can also be made, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com