Light emitting diode (LED) package method and structure

A technology of LED packaging and thermally conductive substrates, applied in lighting devices, lighting and heating equipment, electrical components, etc., can solve the problems of high control requirements for second welding parameters, low product yield, and increase production costs, and achieve flexible and convenient adjustment. The effect of light color tone, low LED junction temperature, and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

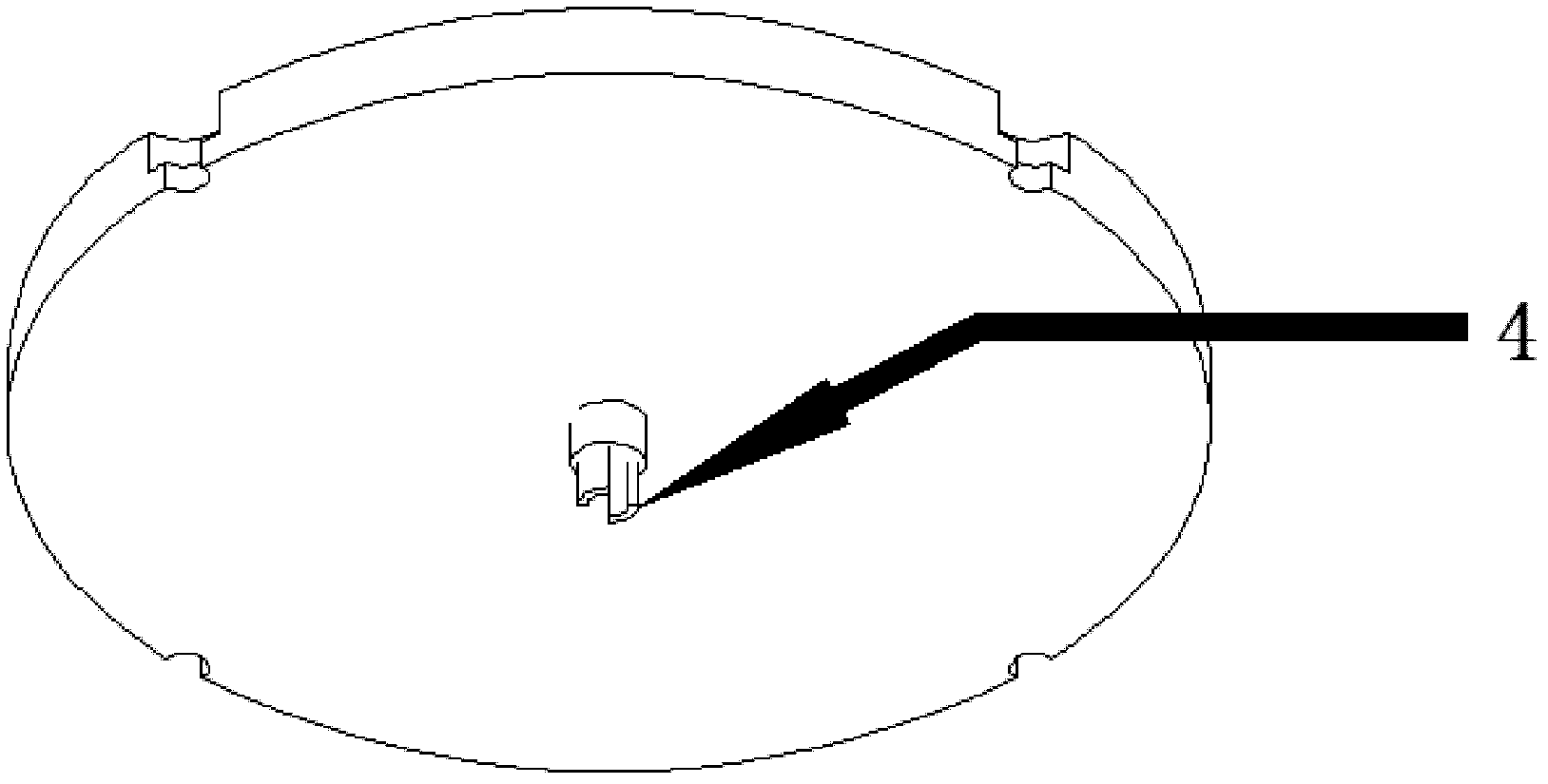

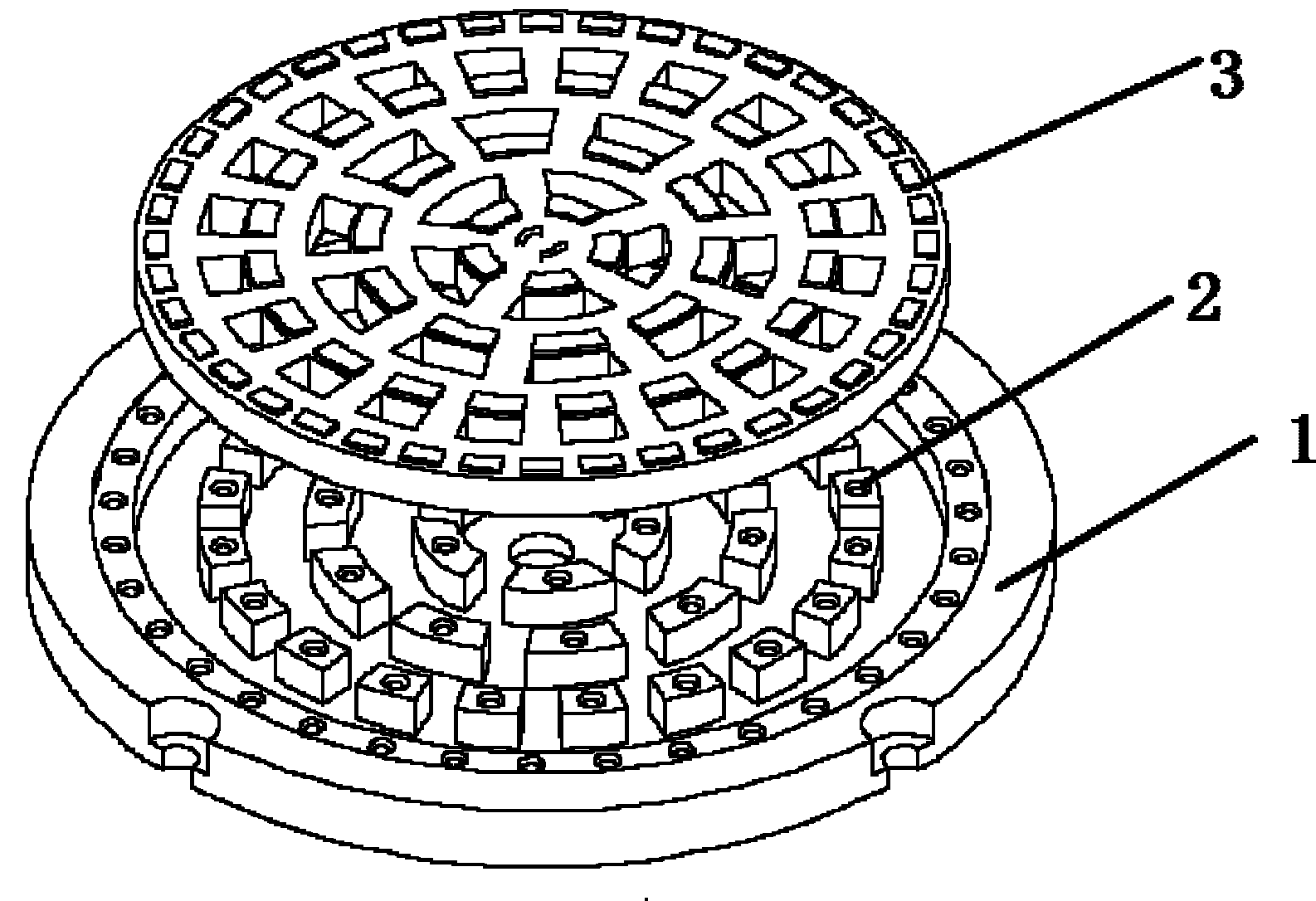

[0018] Example. The invention relates to an LED packaging method. A plurality of independent reflective grooves are set up on an integral heat-conducting substrate, LED chips are fixed in the reflective grooves, and fluorescent powder is injected into them to be baked and solidified. An integral wiring frame is embedded on the heat-conducting substrate, and the connection between each LED chip is realized by performing integral wiring on the wiring frame. The fluorescent powder is solidified into a cup shape. An extraction electrode is provided at the bottom of the heat-conducting substrate.

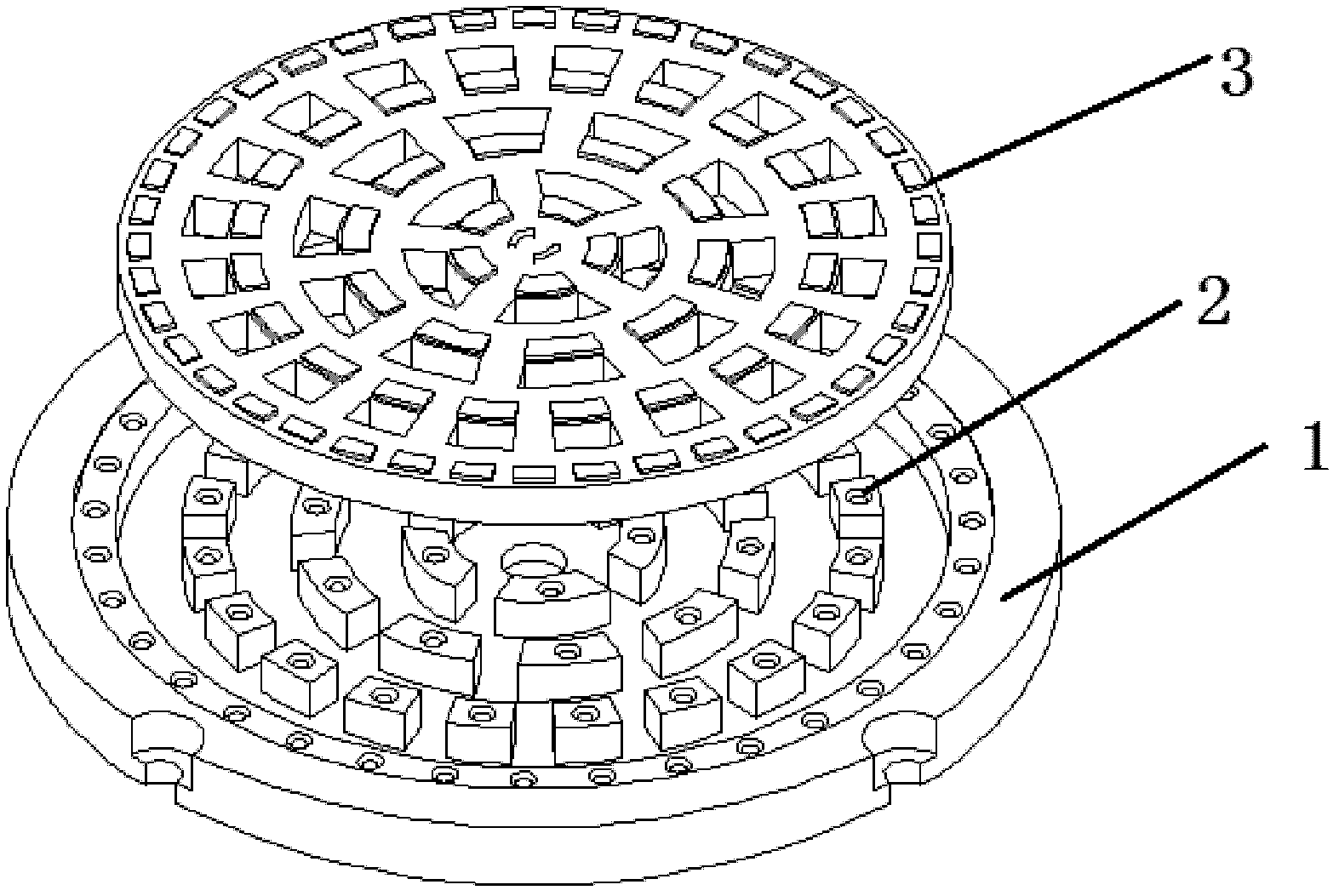

[0019] A kind of LED encapsulation structure that realizes above-mentioned method, such as figure 1 As shown, it includes a heat-conducting substrate 1, on which a reflective groove 2 is opened, and a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com