Method for determining parameters of transmission line overhead ground wire direct-current ice-melting device

A technology for overhead ground wires and transmission lines, which is applied in the direction of overhead installation, cable installation, electrical components, etc. It can solve the problems of not determining the main parameters of the overhead ground wire ice-melting device of transmission lines, etc., achieve good operation prospects, save investment, The effect of reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0045] Technical scheme of the present invention is:

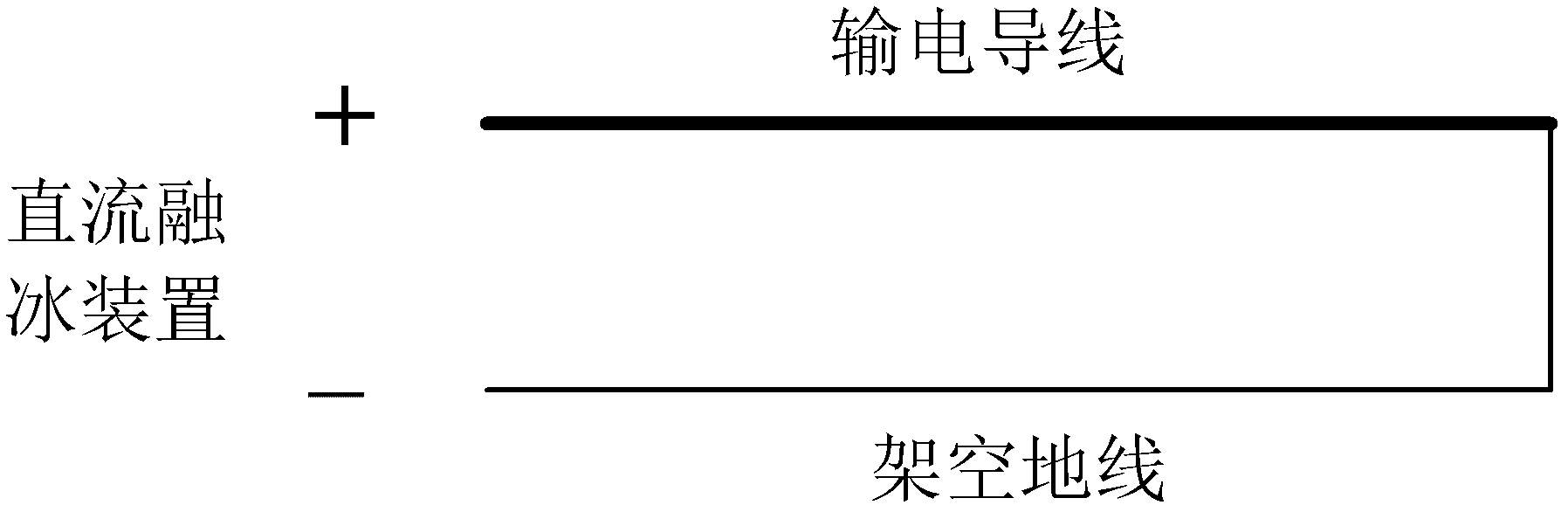

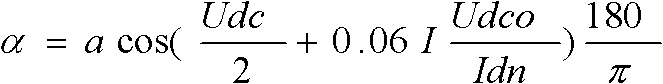

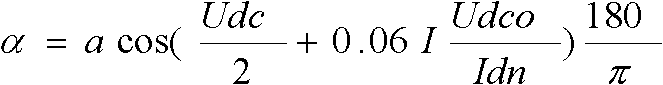

[0046] Firstly, the parameters of each transmission line and overhead ground wire within the scope of application of the DC deicing device for the overhead ground wire of the transmission line are collected, and then the "1+1" DC deicing method is selected, and under comprehensive consideration of various factors, the use of The minimum ice-melting current and the maximum allowable current of each overhead ground wire are calculated by the calculation formulas of the minimum ice-melting current and the maximum allowable current of each overhead ground wire. Combined with the connection mode, the ice-melting current of the overhead ground line DC ice-melting device is determined. Finally, the rated capacity, rated output voltage, operating trigger angle and other parameters of the overhead ground wire drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com