Five-freedom-degree magnetic suspension motor with brake function and control method thereof

A technology with braking function and degrees of freedom, applied in the field of five-degree-of-freedom magnetic levitation motor and its control, can solve the problems of power consumption, reducing and increasing the volume and cost of wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

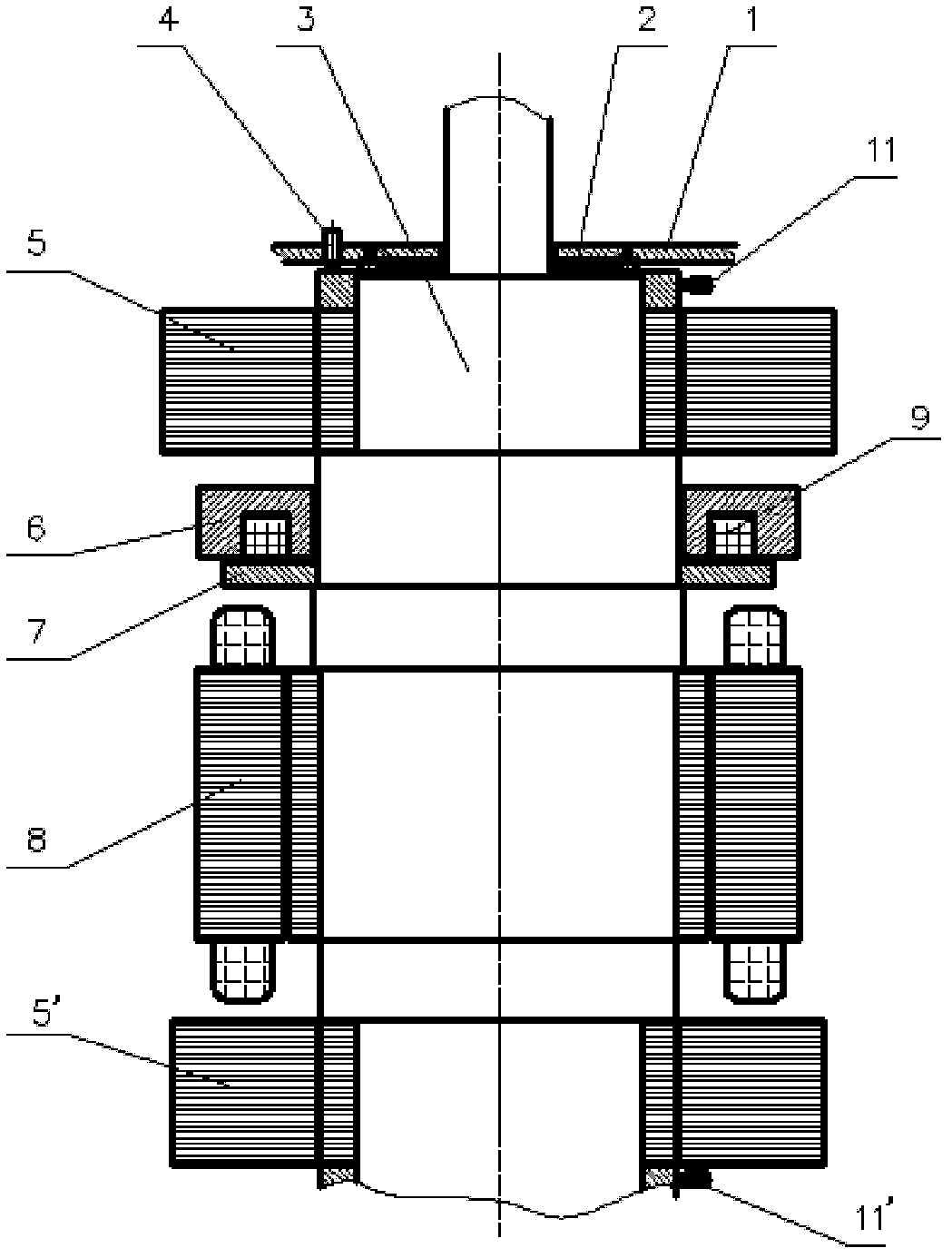

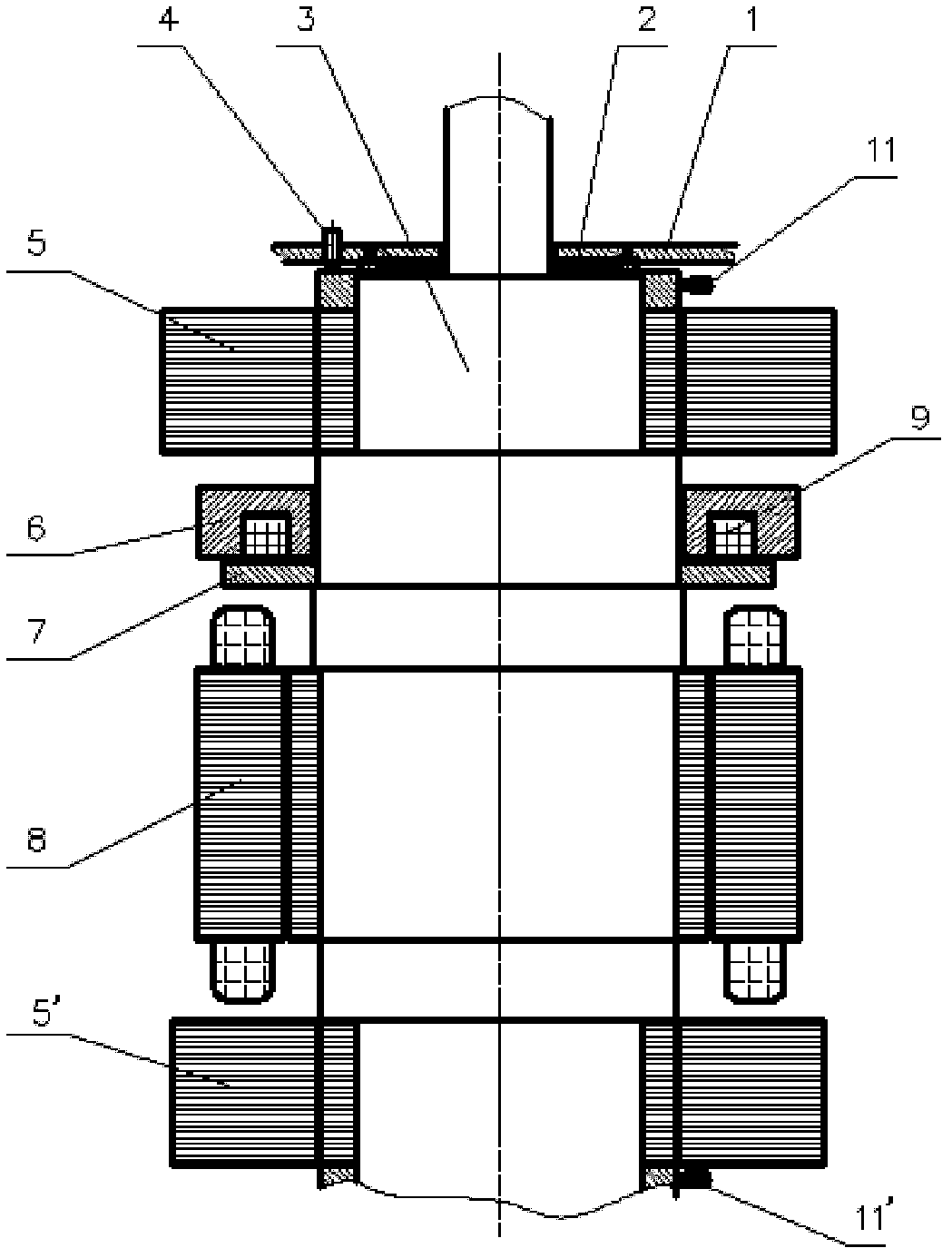

[0019] Such as figure 1 , figure 2 As shown, the present embodiment has a five-degree-of-freedom magnetic levitation motor with a braking function. , motor rotor 3, radial magnetic bearing group (in this example, the radial magnetic bearing group has a first radial magnetic bearing 5 located above the thrust magnetic bearing 6, a second radial magnetic bearing 5' located below the motor stator 8 ), the outer wall of the motor rotor 3 is fixed with a thrust disc 7, a thrust magnetic bearing 6 is arranged above the thrust disc 7, the thrust magnetic bearing 6 is fixed with the motor housing, and the thrust magnetic bearing 6 has an electromagnet coil for attracting the thrust disc 9. The upper end of the motor rotor 3 is provided with a base 1 fixed to the motor housing. The base 1 is equipped with a brake pad 2 and an axial position sensor 4 facing the motor rotor 3. The side of the motor rotor 3 is provided with a The radial position sensor, such as figure 1 In the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com