Method for classifying and packaging tobacco flakes based on size and specification

A technology of large and small sizes and slices, which is applied in the field of tobacco threshing and re-baking processing, can solve the problems of not paying attention to the physical form, and achieve the effects of small changes, reduced costs, and reduced crushing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

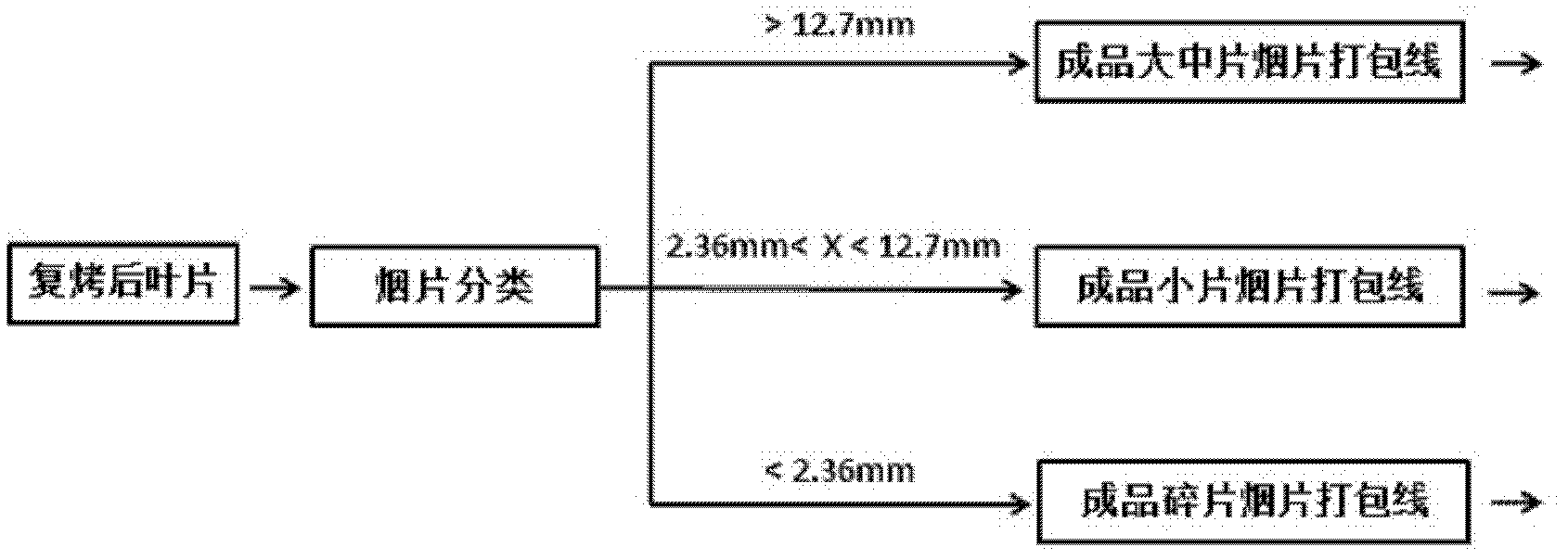

[0018] Such as figure 1 As shown, after re-baking, the tobacco sheets are separated according to the size and specification of the leaves through an orifice-type vibrating screen or other methods. The diameter of the sieve hole is 15mm×15mm and enters the package of the finished large tobacco sheet. The leaves with the diameter of the sieve hole below 5mm×5mm, The blades between 5mm×5mm~15mm×15mm are packaged in small pieces.

[0019] After different leaves are sorted and packaged, they are used as rebaked finished cigarette packs, and then enter the warehouse for targeted aging and use.

[0020] After classification and packaging by this method, for the subsequent classification alcoholization and group processing of silk thread, the subsequent process can adopt targeted processing methods and parameters according to the quality characteristics of different leaves, which provides a basis for effectively comprehensively improving the quality of cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com