Application method for covering sewage pool with telescopic steel membrane structure

An application method and technology of sewage tank, applied in the direction of sedimentation tank, etc., can solve the problems of increased sewage treatment cost, reduced equipment service life, poor flexibility, etc., to save land space and human resources, increase service life, and operate without effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

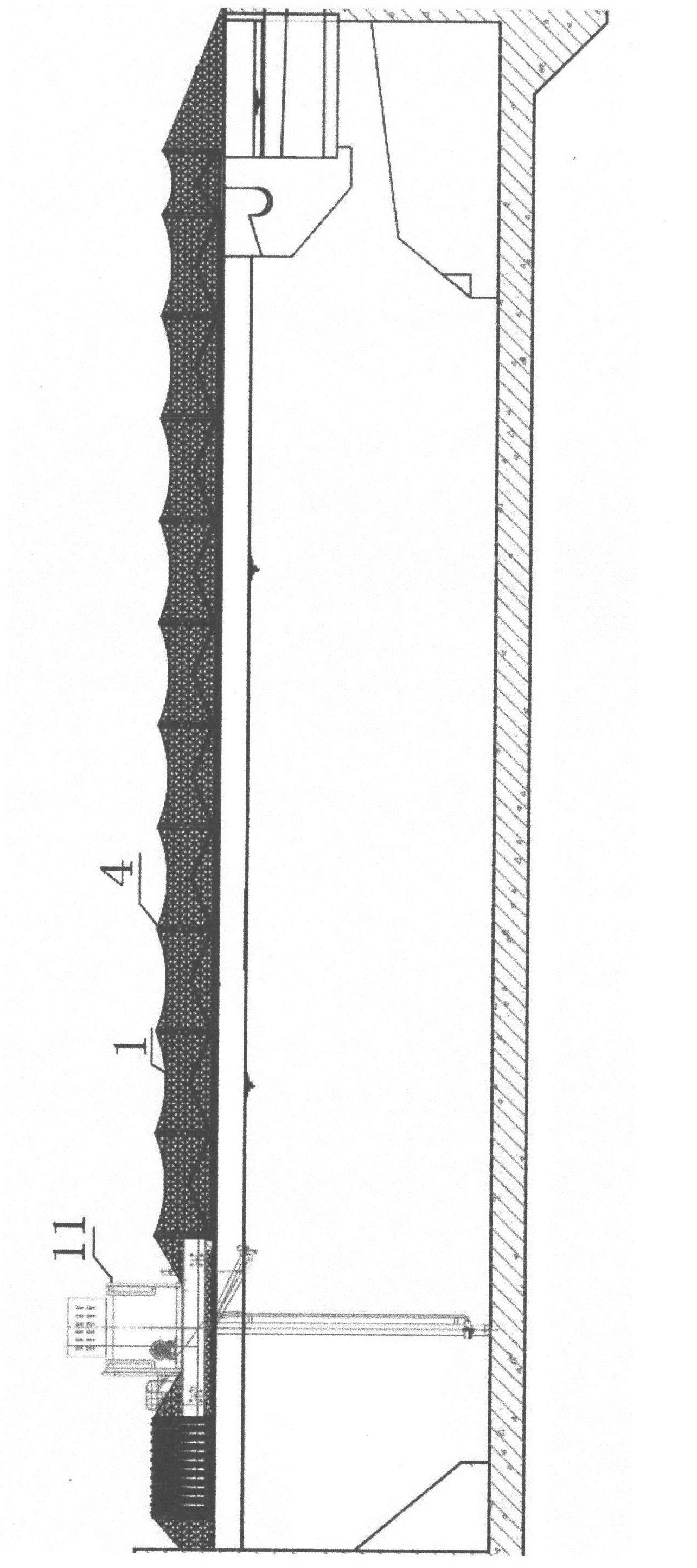

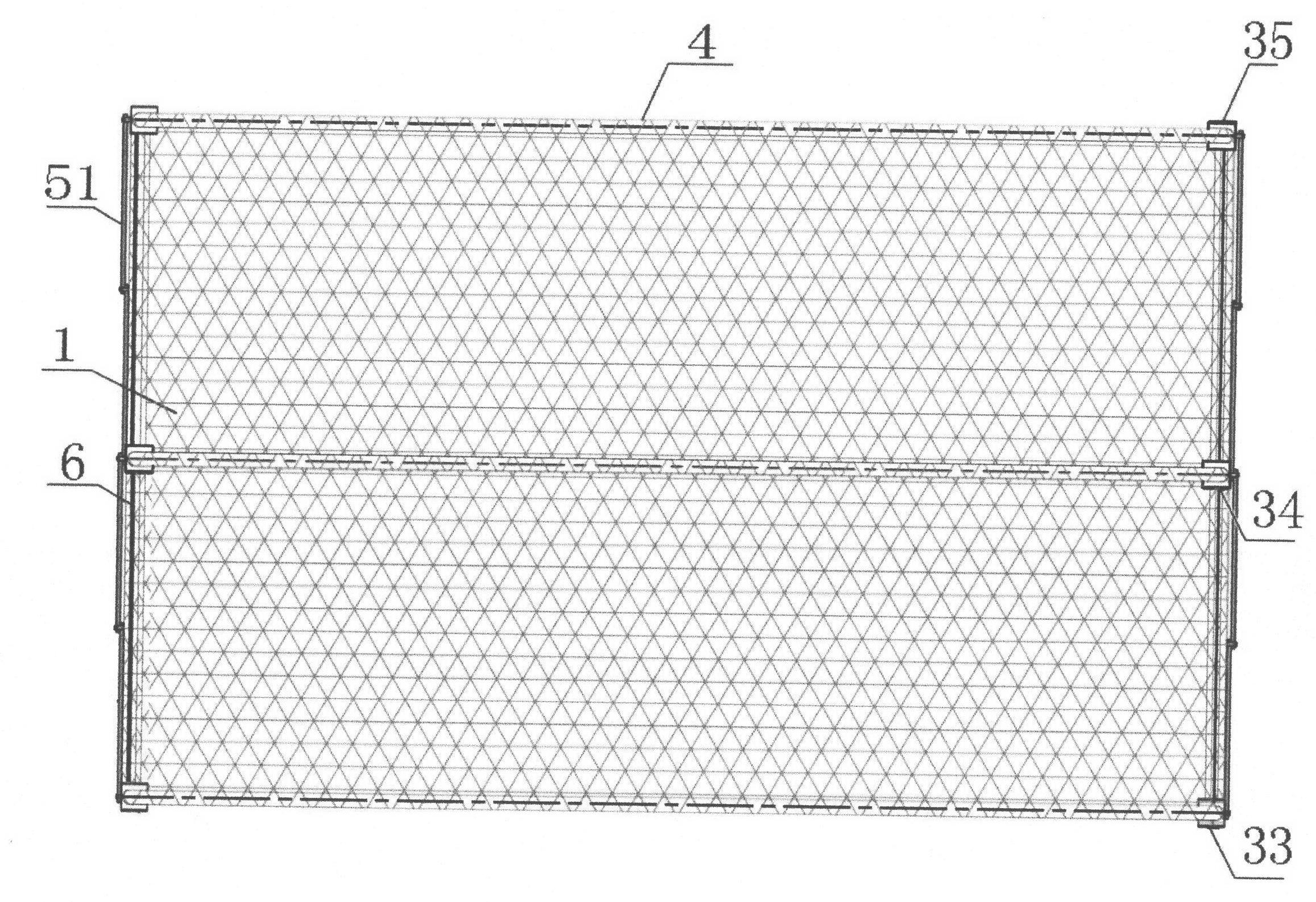

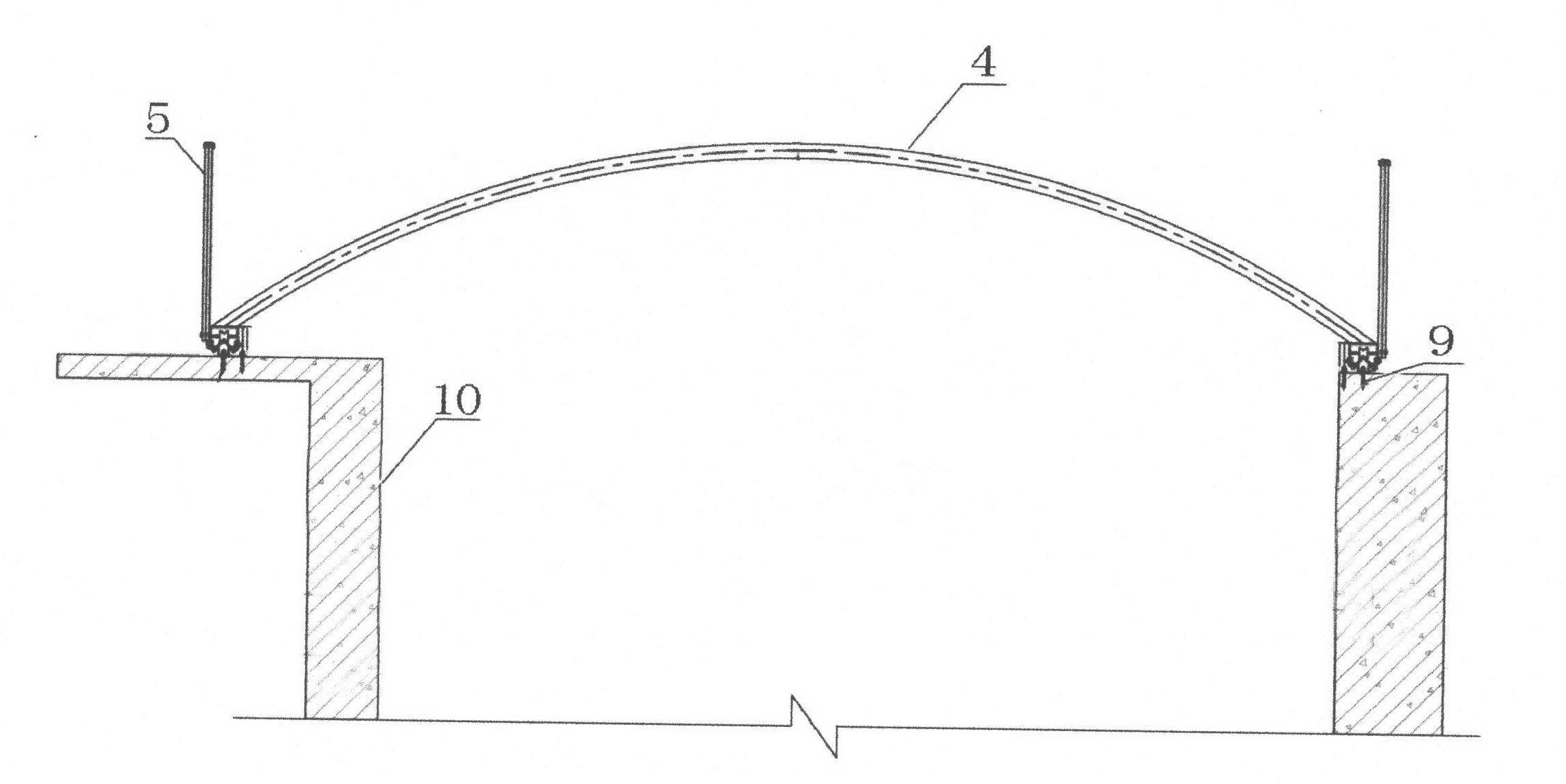

[0018] see Figure 1 to Figure 4 , an application method for capping a telescopic steel film structure in a sewage pool, wherein: the antifouling film 1 is covered on the telescopic support structure by means of telescopic movement, and then the telescopic support structure is connected to the guide rail mechanism; wherein :

[0019] The guide rail mechanism includes a guide rail and a steel wheel assembly; the guide rail includes a wire guide rail 6 and a T-shaped guide rail 2; the wire guide rail 6 is connected to the steel wheel assembly; the middle part of the upper end of the T-shaped guide rail 2 is provided with a triangular support portion 21. The steel wheel assembly includes a steel wheel shell 3, a roller 31 and a steel wheel center shaft 32;

[0020] The telescopic support structure includes an arc-shaped steel pipe skeleton 4, a support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com