Conversion device for ultra-long cable of port machinery in pod operation

A conversion device, port machinery technology, applied in the direction of cranes, transportation and packaging, load suspension components, etc., can solve problems such as cable damage, cable breakage, safety hazards, etc., to ensure safety, prevent equipment damage, and ensure efficient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

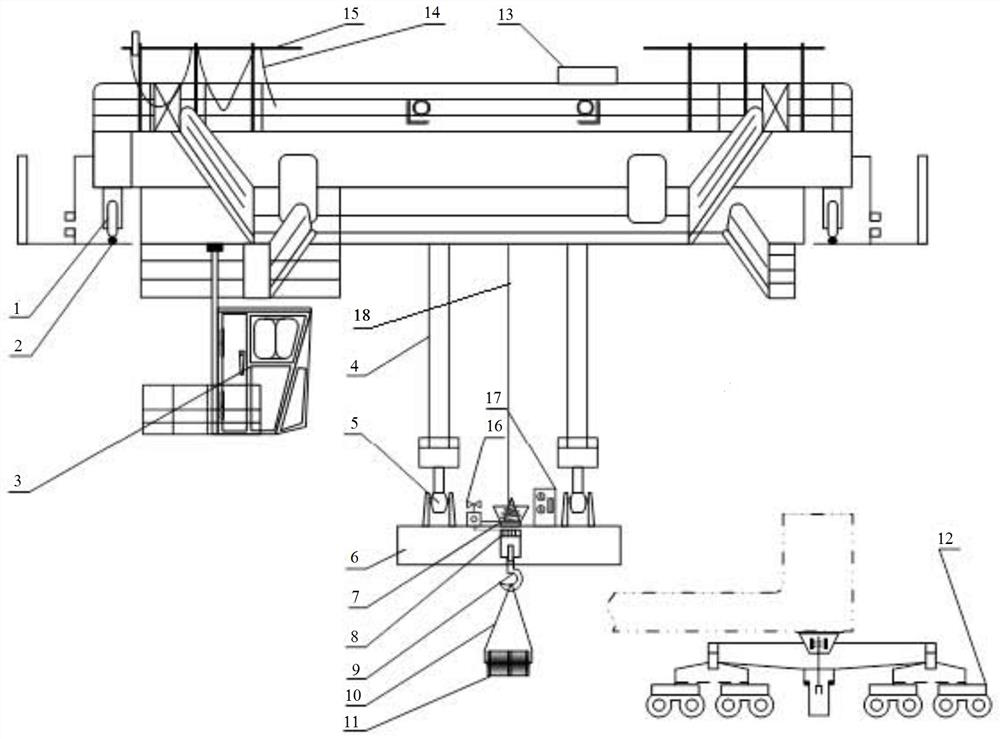

[0032] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0033] The conversion device adopting the ultra-long cable of the pod operation port machine of the present invention realizes the safe operation of the port machine through the conversion of the two operation modes of the dock surface operation and the cabin operation.

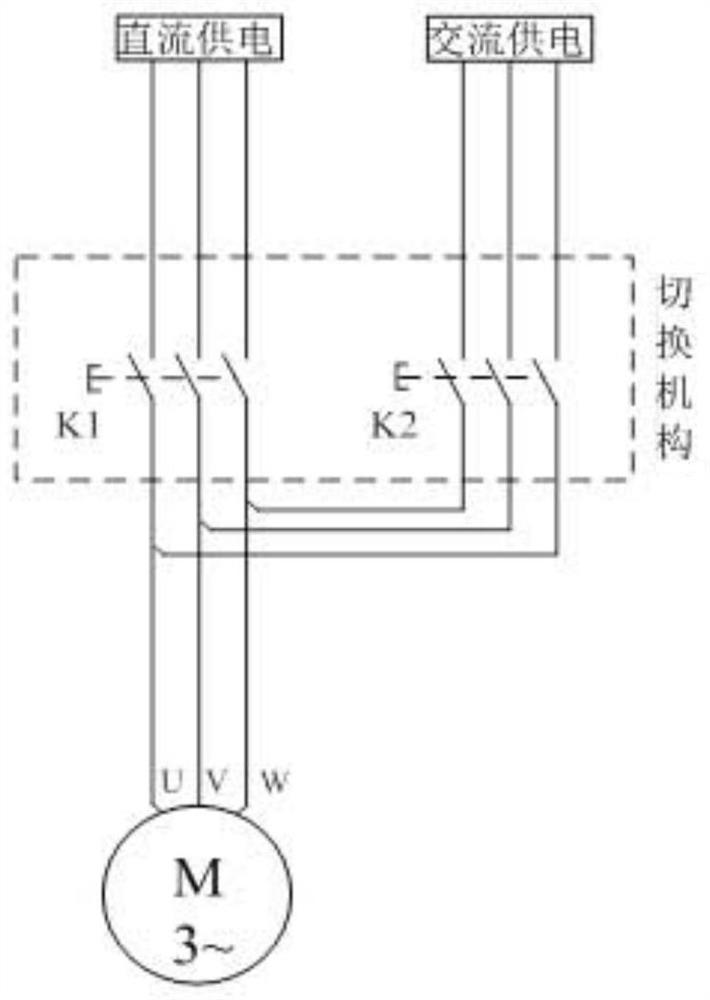

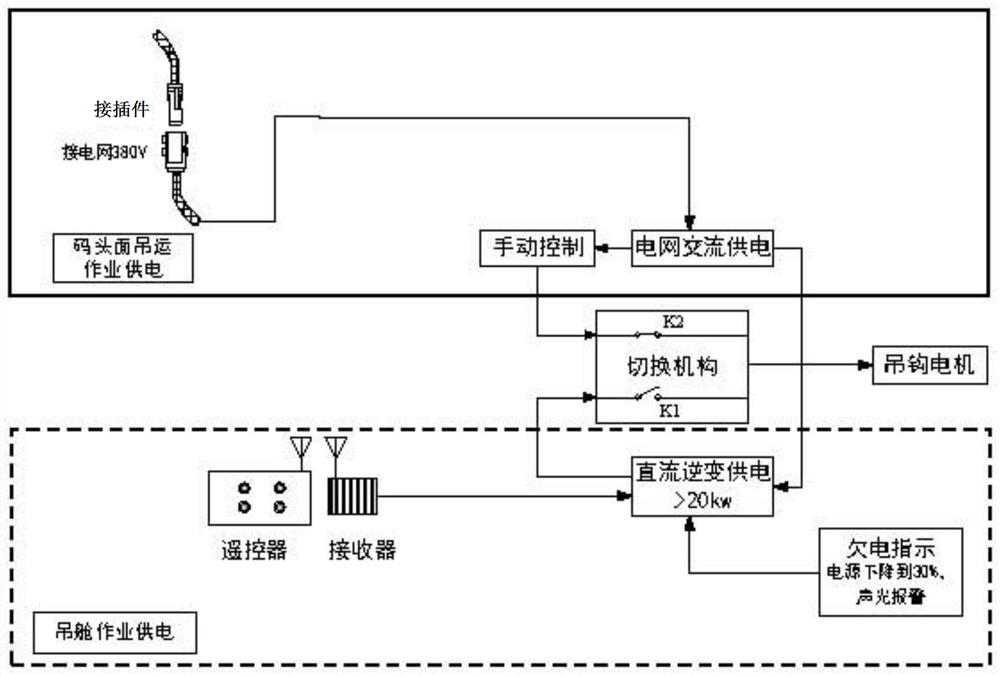

[0034] For cabin lifting operations: see figure 2 , image 3 , Figure 4 with Image 6 , The manual operation switching mechanism 16 switches to DC inverter power supply by closing the first switch K1, the first switch K1 and the second switch K2 are interlocked, and the battery pack supplies power and controls the hook motor 8 to meet the requirements of the port machinery pod During operation, the full-angle rotation of the rotary hook 9 is required. By installing a remote control, that is, equipped with a wireless transmitter, the driver can control the rotation of the hook 9 in the cab 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com