Interface Design Method of Modular Coating Cart for Process Diversity

A technology of interface design and diversity, applied in the design of the interface of printing and coating equipment, can solve the problems of difficult handling, affecting production repeatability, heavy weight, etc., and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

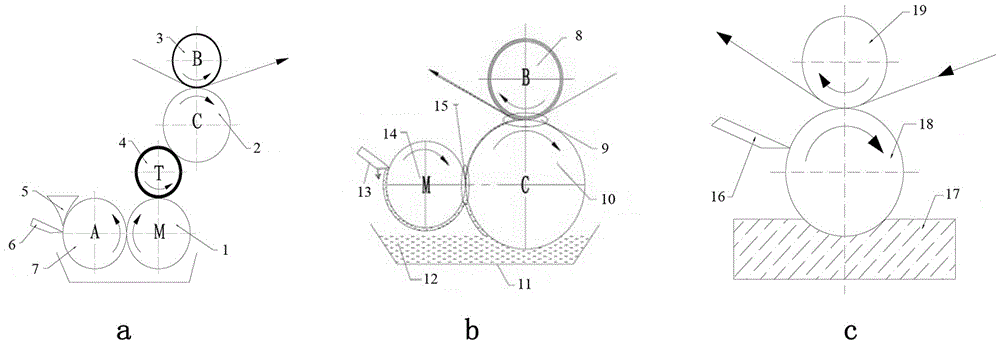

[0026] Reference is made to the above figures. The coating machine is mainly composed of an unwinding device, a coater, a drying device, a deviation correcting device, and a winding device. The coater is the core unit of the coater, and the coating method used is very important to the coater. At present, for the coating film, the main coating methods are direct gravure coating, reverse kiss roll coating, three-roll reverse coating, three-roll offset transfer coating, and five-roll solvent-free coating. Structural schematic diagram and principle diagram see figure 1 .

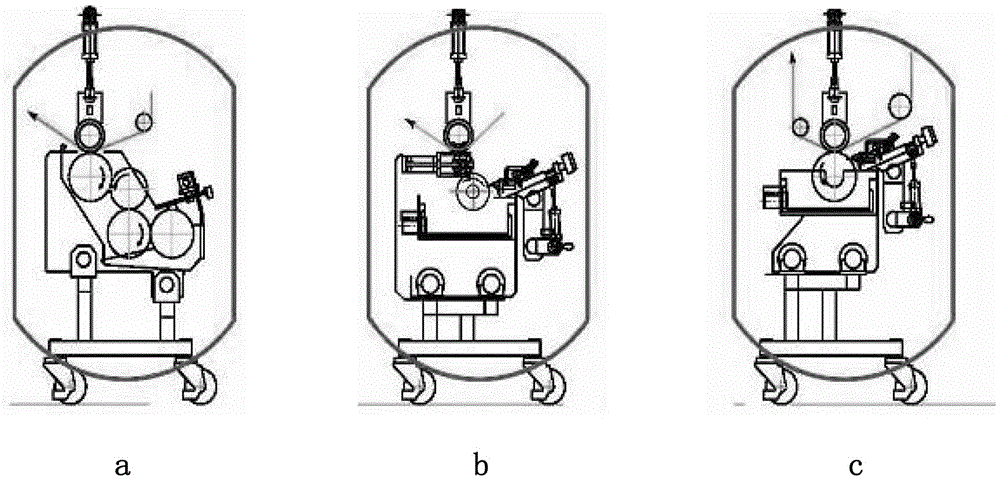

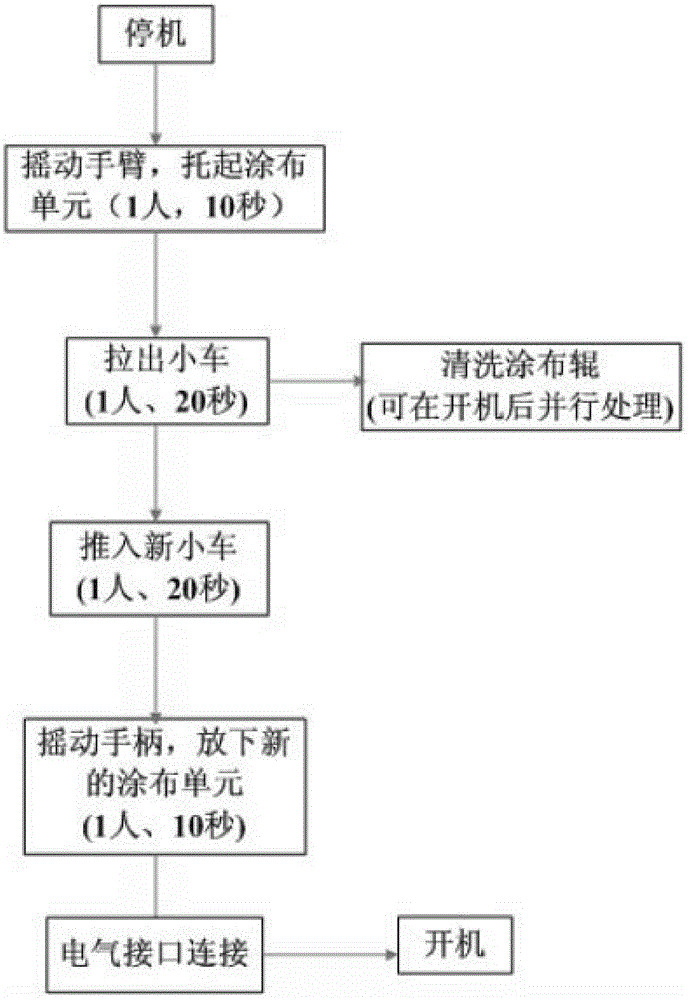

[0027] According to the concept of adaptable interface, the coating unit is designed in the form of a modular coating trolley. By dividing the appropriate module interface, the function and structure of the coating trolley can be determined, and it can be replaced with various coating methods according to research needs. Different coating trolley modules integrate the storage tanks, pumps, feeding and recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com