Intermediate speed grinder

A pulverizer, medium-speed technology, applied in the direction of mechanical material recovery, recycling technology, plastic recycling, etc., can solve the problems of high labor intensity, time-consuming and laborious, affecting work efficiency, etc., to reduce the physical labor intensity and expand the scope of application. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

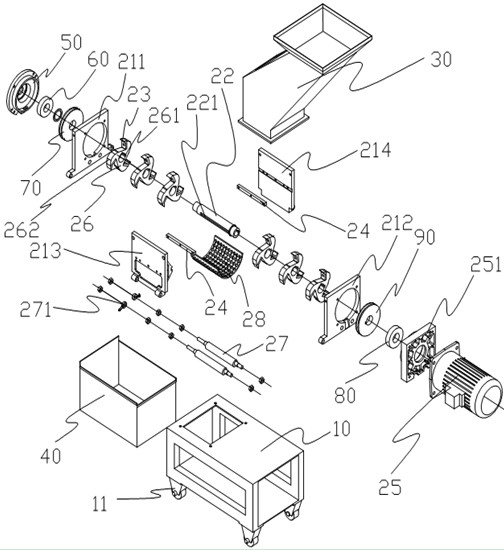

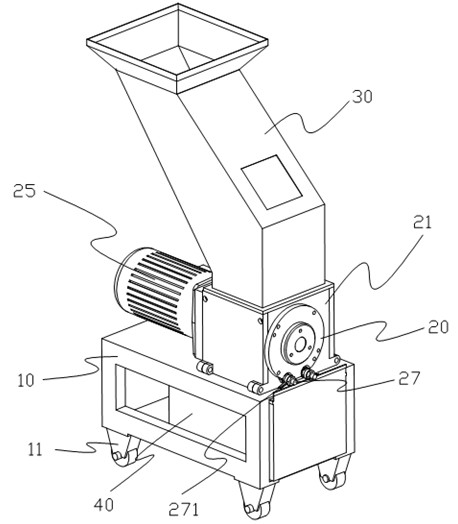

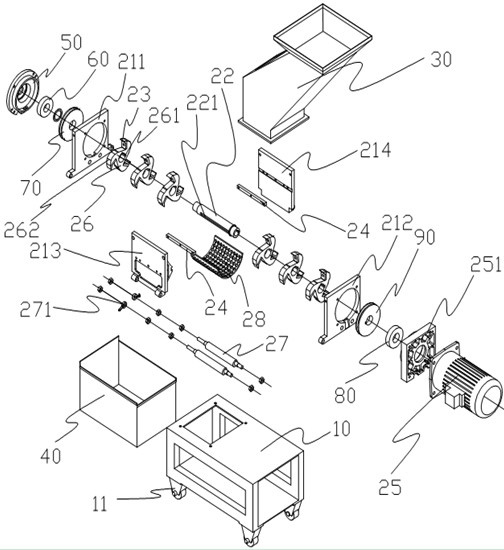

[0022] The present invention includes a base 10 and a middle seat 20 arranged on the base 10, the top of the middle seat 20 is connected to a hopper 30, and the top of the hopper 30 is provided with a trumpet-shaped material inlet to facilitate the entry of waste plastics. The middle seat 20. The bottom end of the crushing center chamber 20 is connected with a lower hopper 40 . The middle seat 20 includes a middle seat wallboard 21 , a roller 22 , a moving knife 23 , a fixed knife 24 and a motor 25 . The motor 25 is fixed on the outer side of the middle seat wall panel 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com