Elevator load testing machine

A load test and elevator technology, which is applied in the direction of elevators, machine/structural component testing, and measuring devices, can solve the problems of time-consuming, labor-intensive labor costs, etc., and achieve the effect of achieving work efficiency, physical labor intensity, and height improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

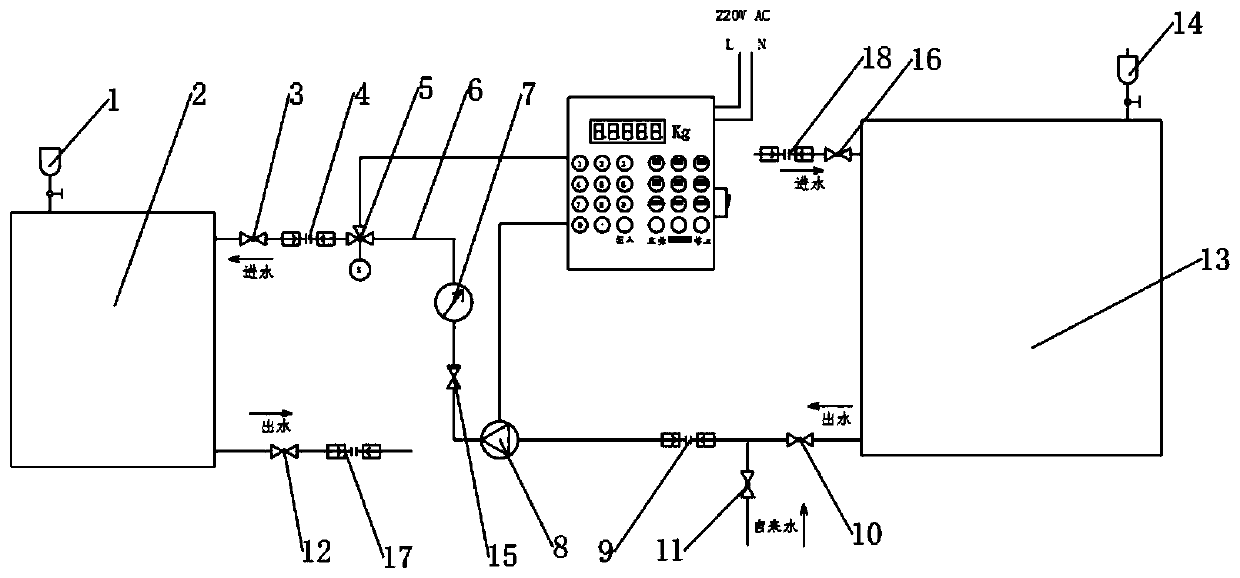

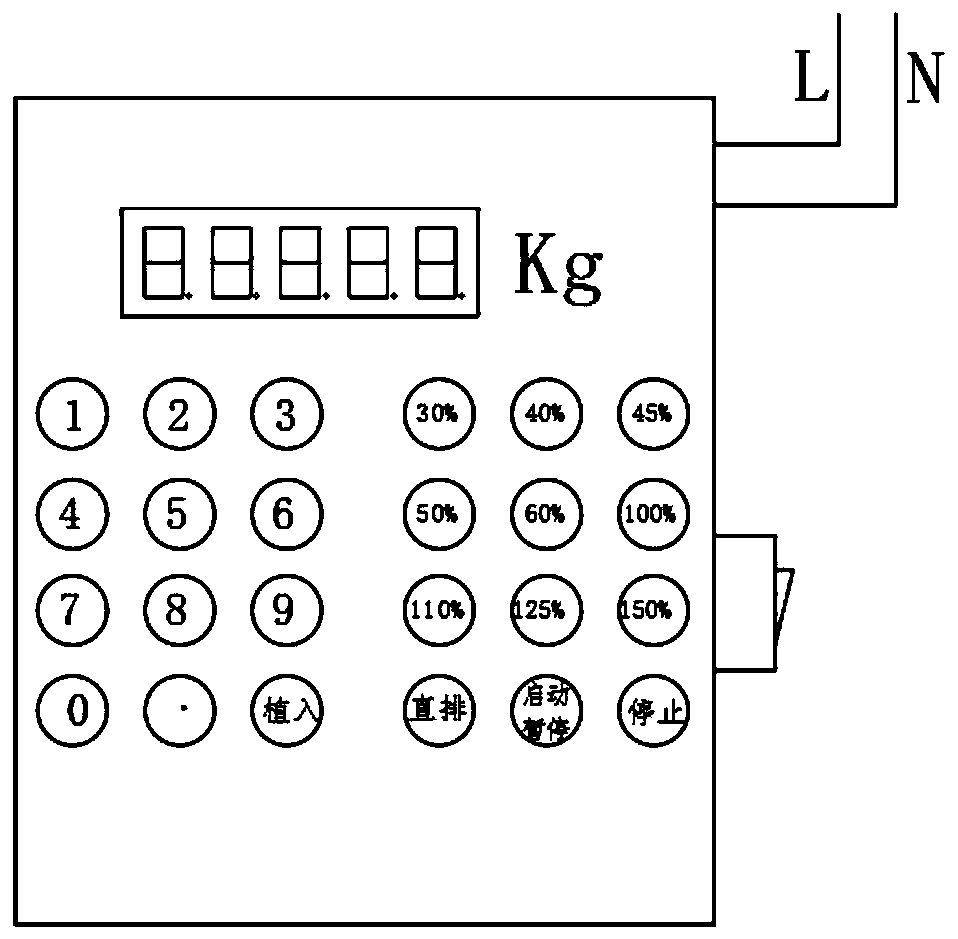

[0019] Depend on Figure 1 ~ Figure 2 Shown, a kind of elevator load testing machine comprises the first water storage device 2, electromagnetic valve 5, water pipe 6, flowmeter 7, water pump 8, the second water storage device 13 and microcomputer controller;

[0020] The first water storage device 2 is provided with a first water storage device exhaust valve 1, a first water storage device inlet valve 3 and a first water storage device outlet valve 12, and the first water storage device exhaust valve 1 is fixedly connected to The top of the first water storage device 2, and the exhaust valve 1 of the first water storage device communicates with the interior of the first water storage device 2, the first water storage device inlet valve 3 is located at the upper end of the first water storage device 2, the first water storage device 2 A water storage device outlet valve 12 is located at the lower end of the first water storage device 2, the first water storage device inlet val...

Embodiment 2

[0025] In this embodiment, the first water storage device 2 and the second water storage device 13 are water bags, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com