Plunger pump crankshaft grinding device and application method

A grinding device and plunger pump technology, which is applied in the direction of grinding devices, grinding drive devices, grinding machine tools, etc., can solve the problems of affecting the maintenance work of plunger pumps, wasting manpower, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

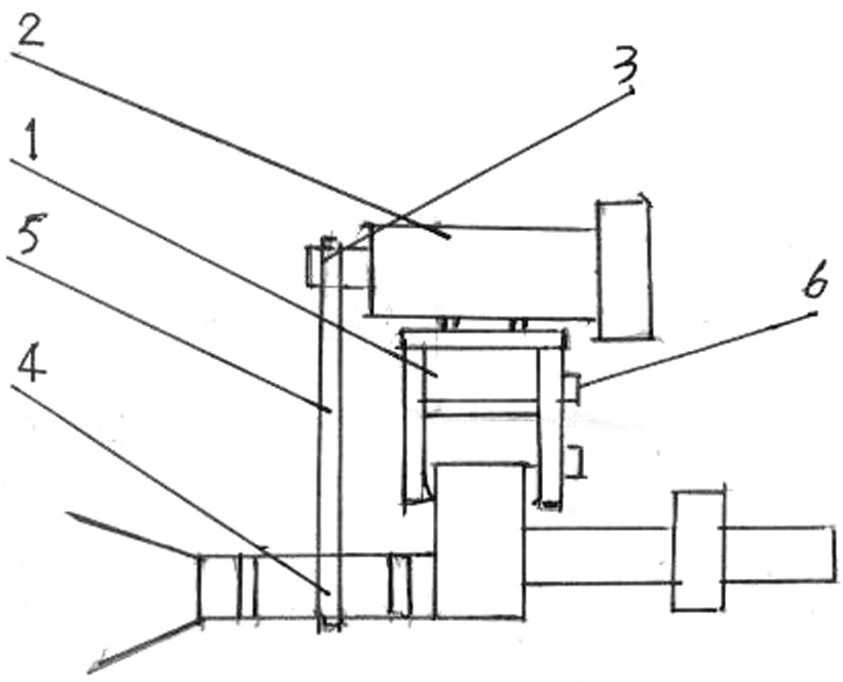

[0010] Embodiment 1, the present invention comprises base 1, drive motor 2, drive pulley 3, sandpaper wheel 4, transmission belt 5, bolt 6, and described drive motor 2 is fixed on the base 1, and drive pulley 3 is installed on the drive motor 2; Drive belt pulley 3 is connected with sandpaper wheel 4 by transmission belt 5.

Embodiment 2

[0011] Embodiment 2, the base 1 is fixed on the crankshaft balance weight by two bolts 6, the two bolts 6 are connected to the outside of the base 1, and the two bolts are adjustable.

Embodiment 3

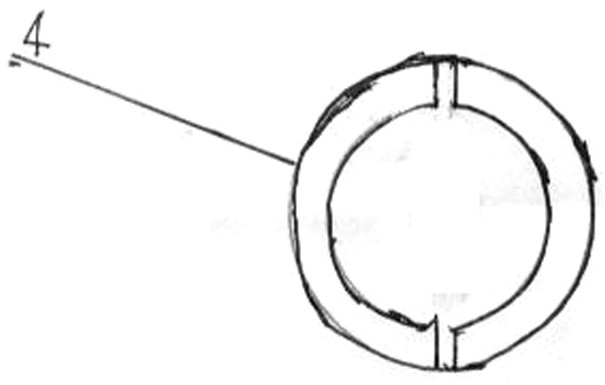

[0012] Embodiment 3. The sandpaper wheel 4 is composed of two 180-degree semicircular tiles, two pieces of sandpaper are respectively installed in the middle of the two semicircular tiles, and the two semicircular tiles clamp both sides of the sandpaper to fix the sandpaper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com