Single cylinder type automatic feed mechanism

An automatic feeding and single-cylinder technology, applied in the field of mechanical feeding mechanism, can solve the problems of synchronous work difference of power source, tilting of materials lifted up, affecting the service life of equipment, etc., and achieve low manufacturing cost and long service life of equipment , The humanized effect of equipment structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

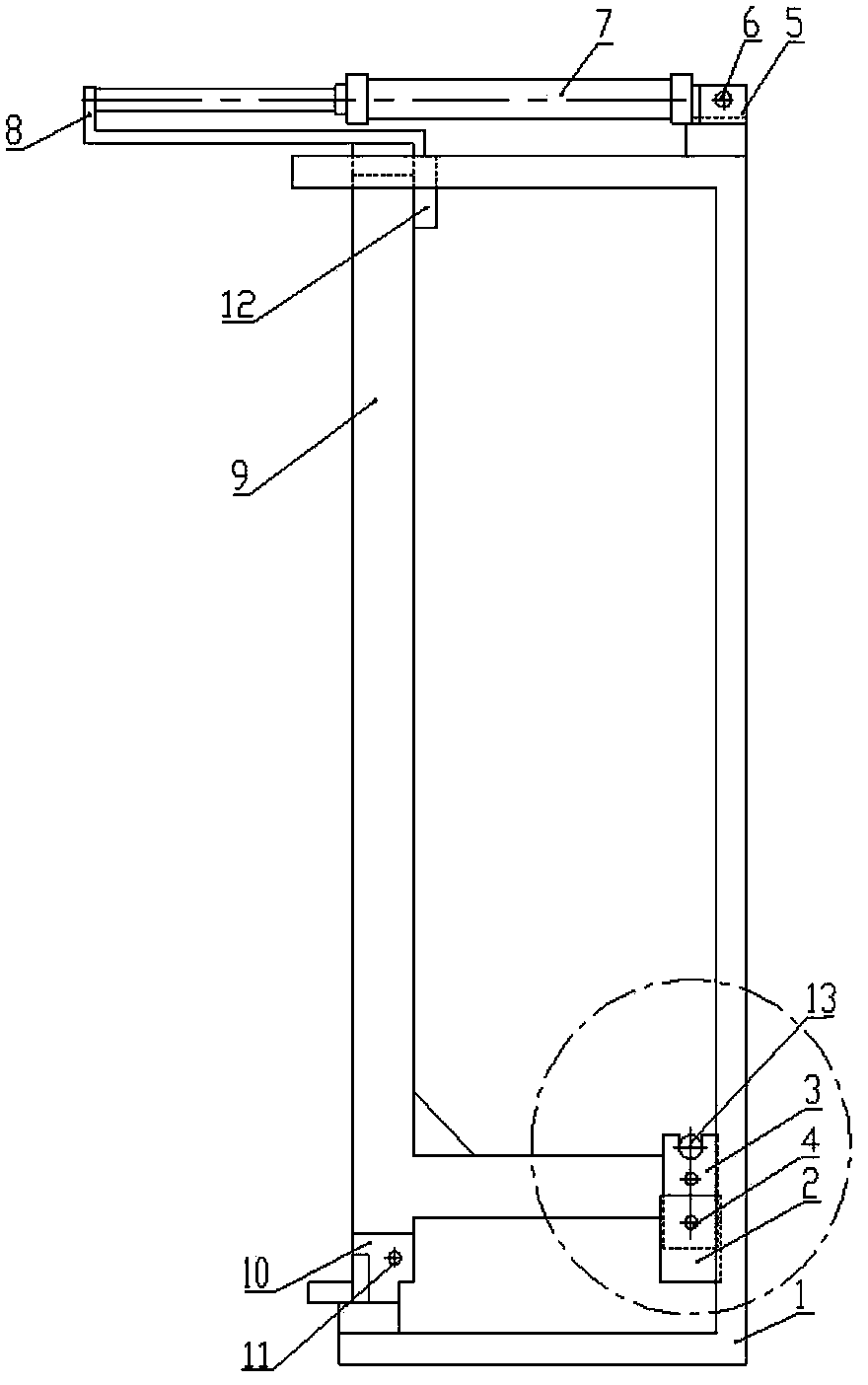

[0021] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

[0022] As shown in the figure, a single-cylinder automatic feeding mechanism is used for feeding plastic blister machines, including the following components:

[0023] 1), fixed frame 1;

[0024] 2), material rack 9;

[0025] The side of the material rack 9 is "L" shaped, including a vertical riser and a horizontal bottom plate arranged at the bottom of the riser. One end of the bottom plate is fixedly connected with the vertical plate, and the free end of the other end is provided with a material seat 3 and a height adjustment base 2 . Viewed from the front, the material rack 9 is provided with a set of vertical plates and bottom plates on both sides. The two vertical plates are connected by push rods. The material seats 3 are arranged symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com