Detachable flat car

A flatbed, disassembled technology, used in motor vehicles, vehicle parts, transportation and packaging, etc., can solve the problems of irregular chassis structure, high transportation cost, long production cycle, etc., to facilitate modular replacement and expand delivery. range, the effect of reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] When the present invention describes the orientation, the direction in which the flatbed truck travels normally is the front, and the opposite side to the front is the rear.

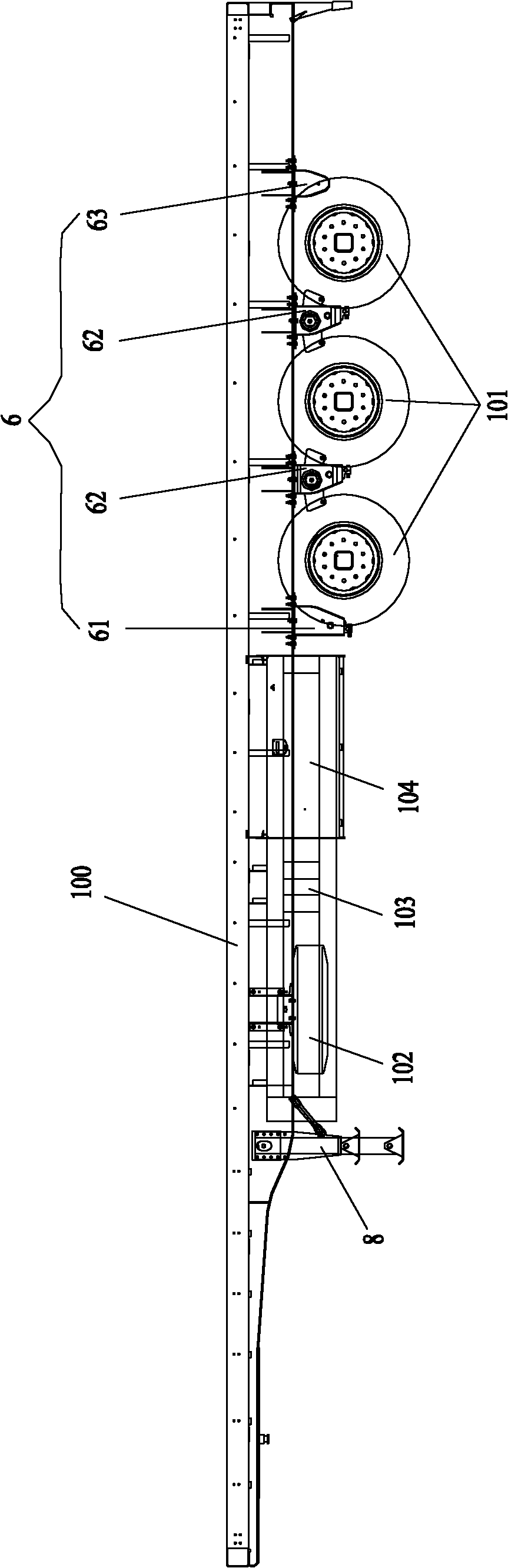

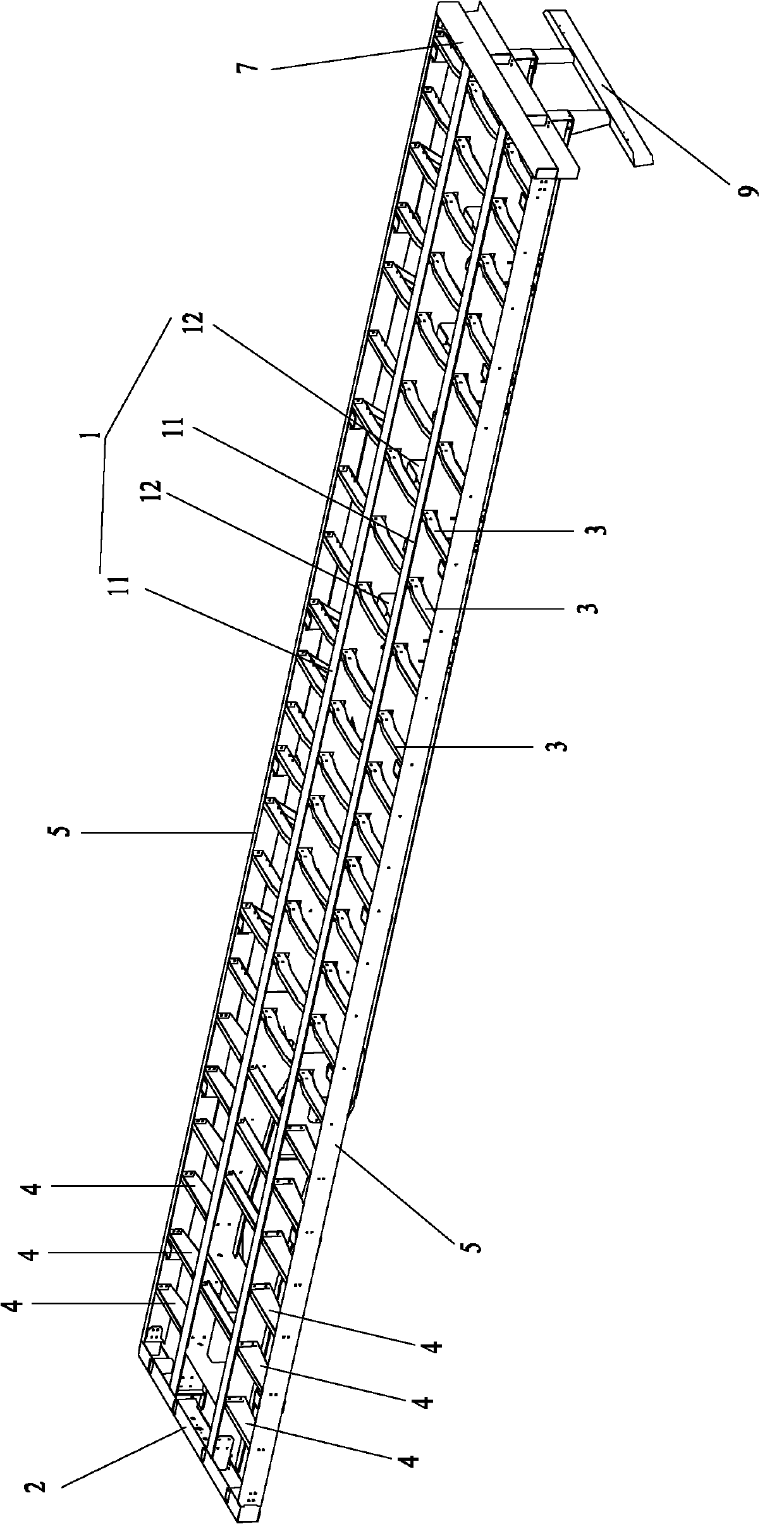

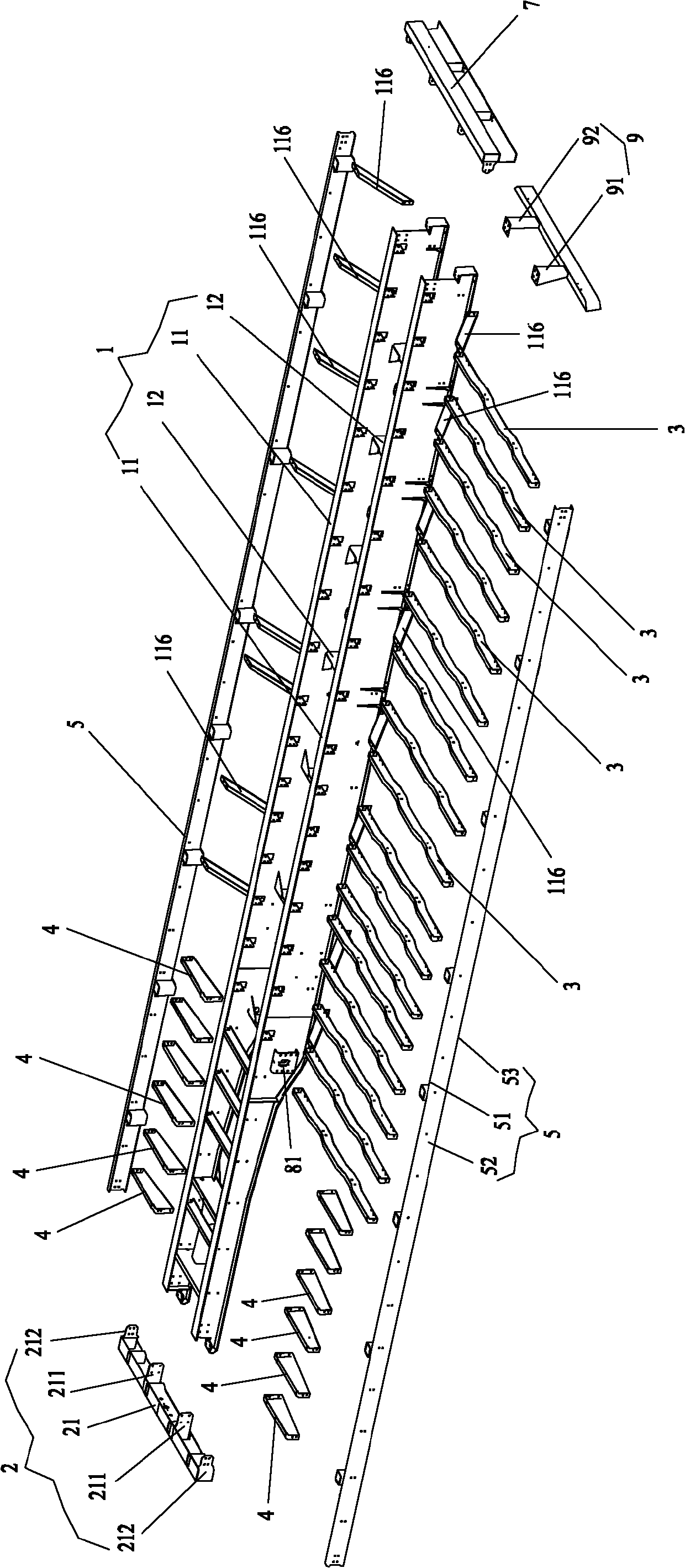

[0052] refer to figure 1 , the detachable flatbed truck includes: chassis 100, wheel assembly 101 installed on the chassis 100, spare tire assembly 102, guardrail assembly 103, tool box assembly 104, suspension assembly 6 and support device 8 Wait. The wheel assembly 101 is installed under the rear part of the underframe through the suspension assembly 6, and is connected to the suspension assembly 6 in a detachable manner. The support device 8 is detachably connected to the front of the middle part of the underframe. , the guardrail assembly 103 and the tool box assembly 104 are located between the supporting device 8 and the wheel assembly 101, and are also connected to the underframe 100 in a detachable manner.

[0053] The structures of the wheel assembly 101, the spare tire assembly 102, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com