Framework vehicle and front end beam thereof

A frame car and frame technology, applied in the field of frame cars, can solve the problems of damage to the surface paint of the main beam, uncompact frame workshop, heavy welding workload, etc., and achieve the effects of convenient modular replacement, improved transportation efficiency, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

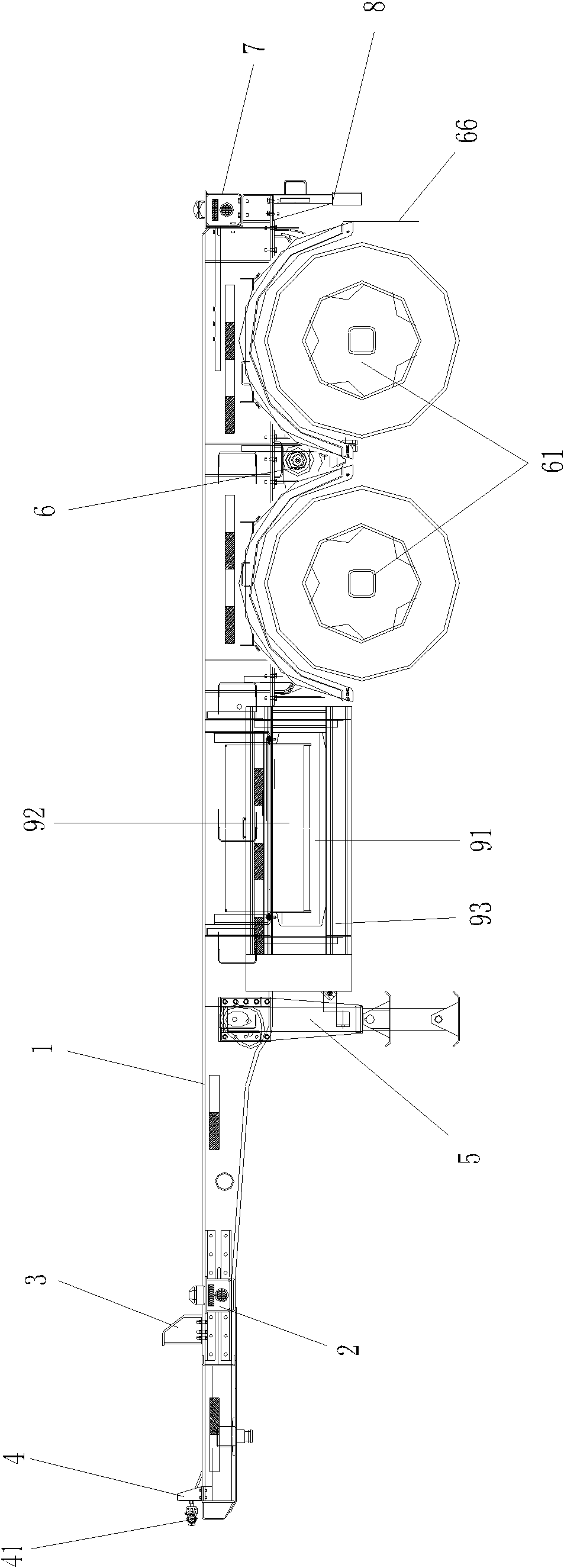

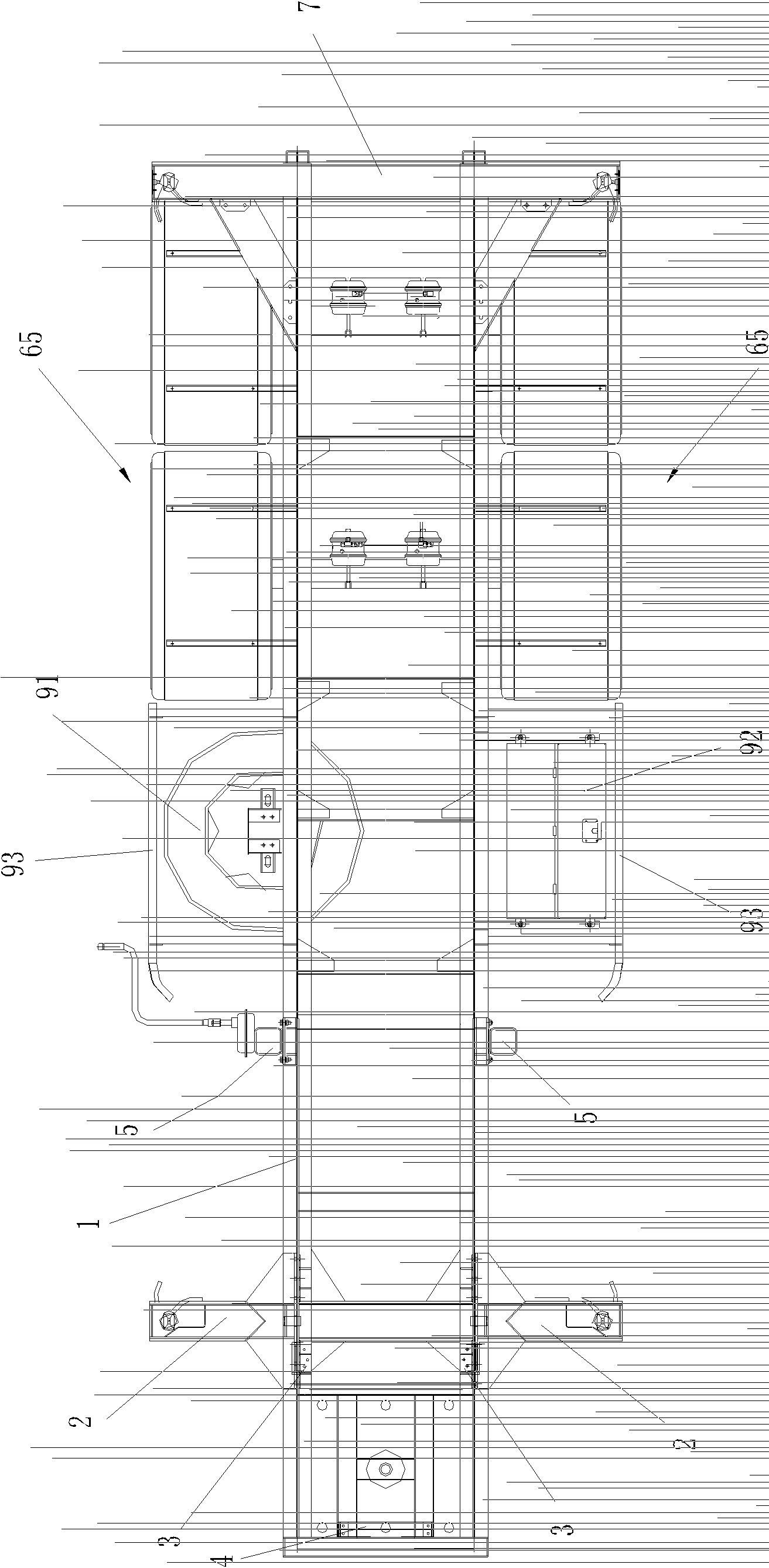

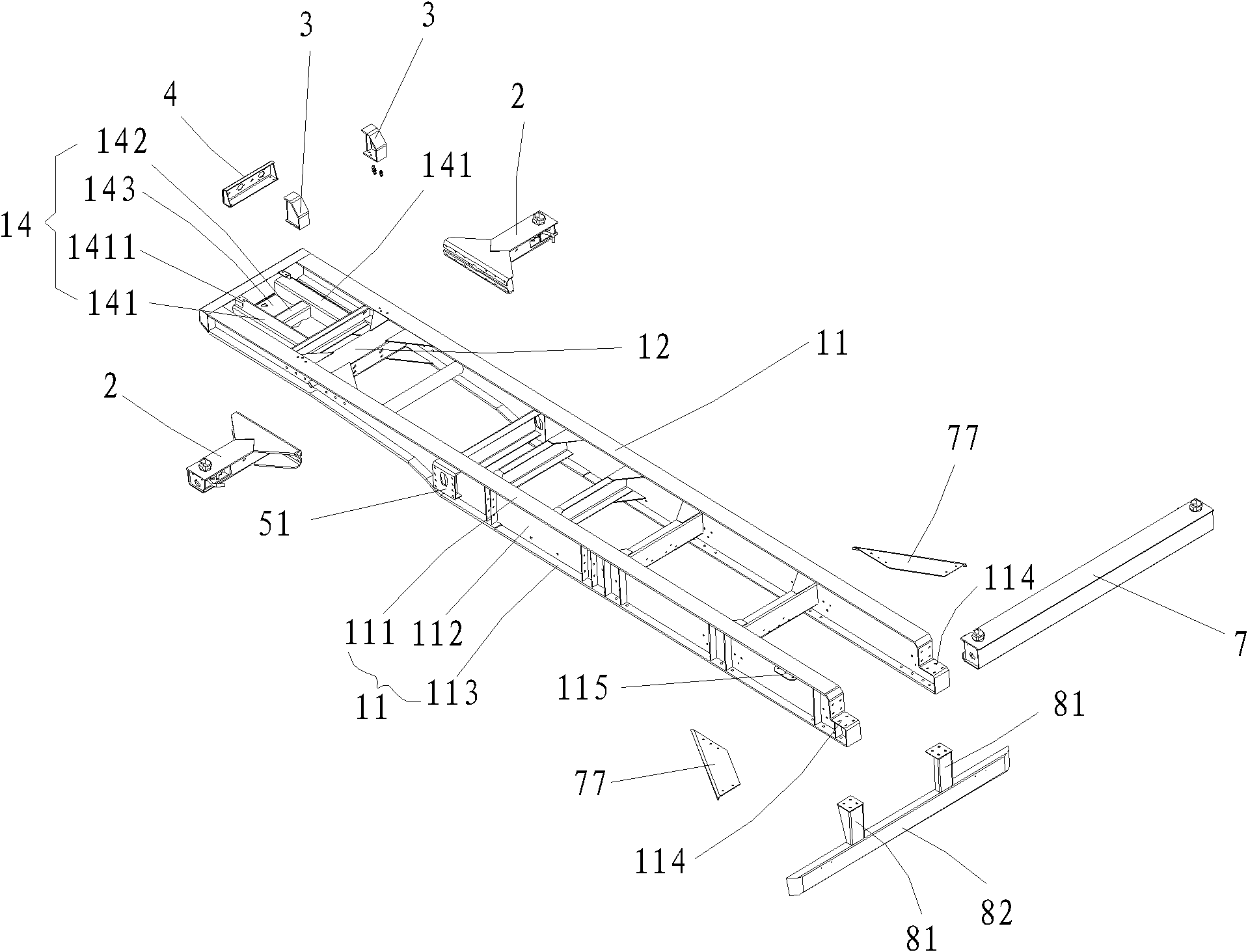

[0029] refer to Figure 1-2 , the detachable skeleton vehicle includes a vehicle frame main body 1 . A pair of symmetrically arranged front end beams 2 are detachably connected to both sides of the front part of the vehicle frame body 1 . A pair of guide blocks 3 are detachably connected to the front of the frame main body 1 and slightly in front of the front end beam 2, and the guide blocks 3 are used for positioning and guiding when the frame vehicle transports containers. An air joint bracket 4 is detachably connected to the front of the frame body 1 near the front end. A brake system 41 is detachably mounted on the air joint bracket 4 , and a cylinder that cooperates with the brake system 41 is detachably mounted below the rear part of the vehicle frame main body 1 . A support device 5 for supporting the frame body 1 is detachably installed at the front of the middle part of the frame body 1 and below the rear of the front end beam 2 . Two symmetrically arranged suspens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com