Fabrication method of power generation assembly for evaporative power generation

A technology of power generation components and electrodes, which is applied in the field of new energy power generation equipment, can solve the problems of poor stability of evaporative power generation devices and fragile carbon materials, and achieve the effects of improving materials and methods, increasing strength, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the power generation component for evaporative power generation provided in Example 1 is as follows:

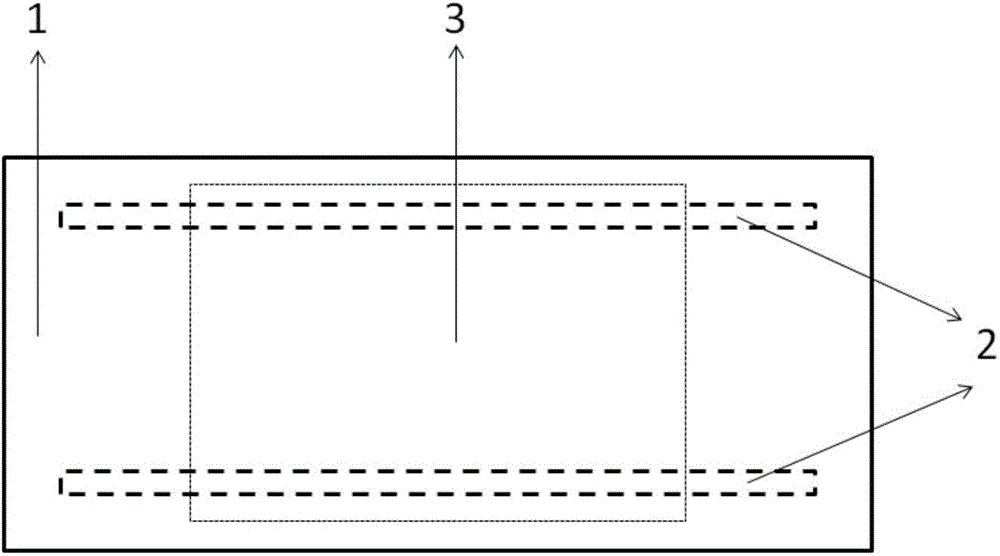

[0029] (1) The ceramic sheet is ultrasonically cleaned with acetone, ethanol, and deionized water for ten minutes in sequence, dried, and then two non-intersecting electrodes are prepared on the surface using conductive materials;

[0030] (2) carbon black, ethyl cellulose and terpentetol are ground in a ratio of 1:0.1:1 by mass to make a uniformly dispersed slurry;

[0031] (3) Print the above slurry with a thickness of 200 microns between the two electrodes to form a slurry layer;

[0032] (4) Anneal the printed paste layer at a temperature of 220 degrees Celsius to form a carbon material layer between the two electrodes, and the annealing time is 4 hours; complete the preparation of the power generation component for evaporative power generation.

Embodiment 2

[0033] The preparation method of the power generation component for evaporative power generation provided in Example 2 is as follows:

[0034] (1) The glass sheet is ultrasonically cleaned with acetone, ethanol, and deionized water for ten minutes in sequence, dried, and then two mutually disjoint electrodes are prepared on the surface using conductive materials;

[0035] (2) carbon black, ethyl cellulose and ethanol were stirred for 12 hours in a ratio of 1:10:20 by mass to make a uniformly dispersed slurry;

[0036] (3) Print the above slurry with a thickness of 10 microns between the two electrodes to form a slurry layer;

[0037] (4) Anneal the printed paste layer at a temperature of 500 degrees Celsius to form a carbon material layer between the two electrodes, and the annealing time is 1 hour; complete the preparation of the power generation component for evaporative power generation.

Embodiment 3

[0038] The preparation method of the power generation component for evaporative power generation provided in Example 3 is as follows:

[0039] (1) The glass sheet is ultrasonically cleaned with acetone, ethanol, and deionized water for ten minutes in sequence, dried, and then two mutually disjoint electrodes are prepared on the surface using conductive materials;

[0040](2) carbon black, ethyl cellulose, terpentetol and glacial acetic acid were stirred at 70 degrees Celsius for 6 hours in a mass ratio of 1:1:5:0.5 to make a uniformly dispersed slurry;

[0041] (3) Print the above slurry with a thickness of 50 microns between the two electrodes to form a slurry layer;

[0042] (4) Perform annealing treatment on the printed paste layer at a temperature of 380 degrees Celsius; to form a carbon material layer between the two electrodes, the annealing time is 2 hours; complete the preparation of the power generation component for evaporative power generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com