Egg feeding device for egg production line

A production line and egg technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of not keeping up with the speed requirements of the inspection and packaging line, not suitable for egg production lines, and high work intensity, so as to reduce labor costs and labor intensity, The effect of easy processing and production line installation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

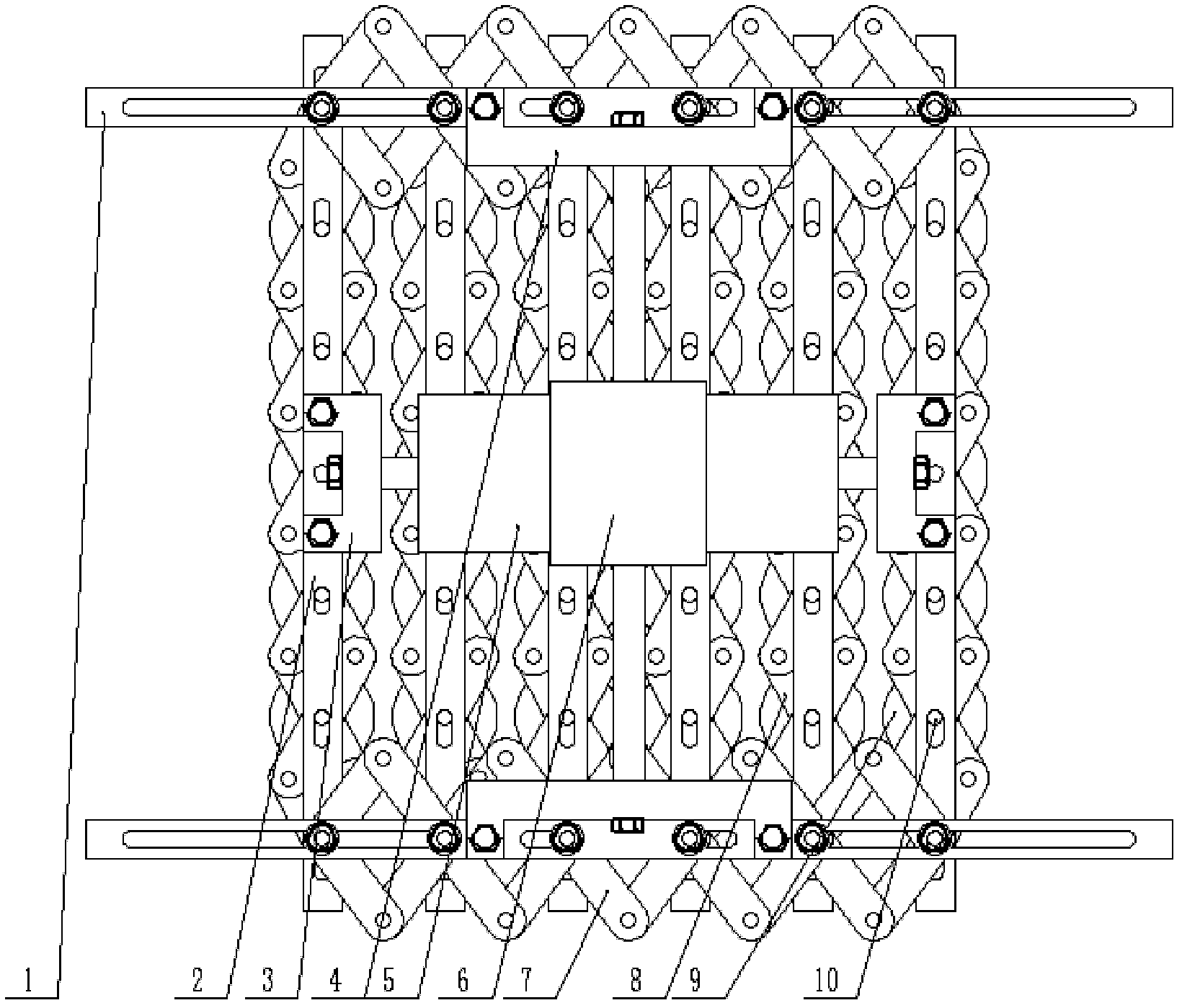

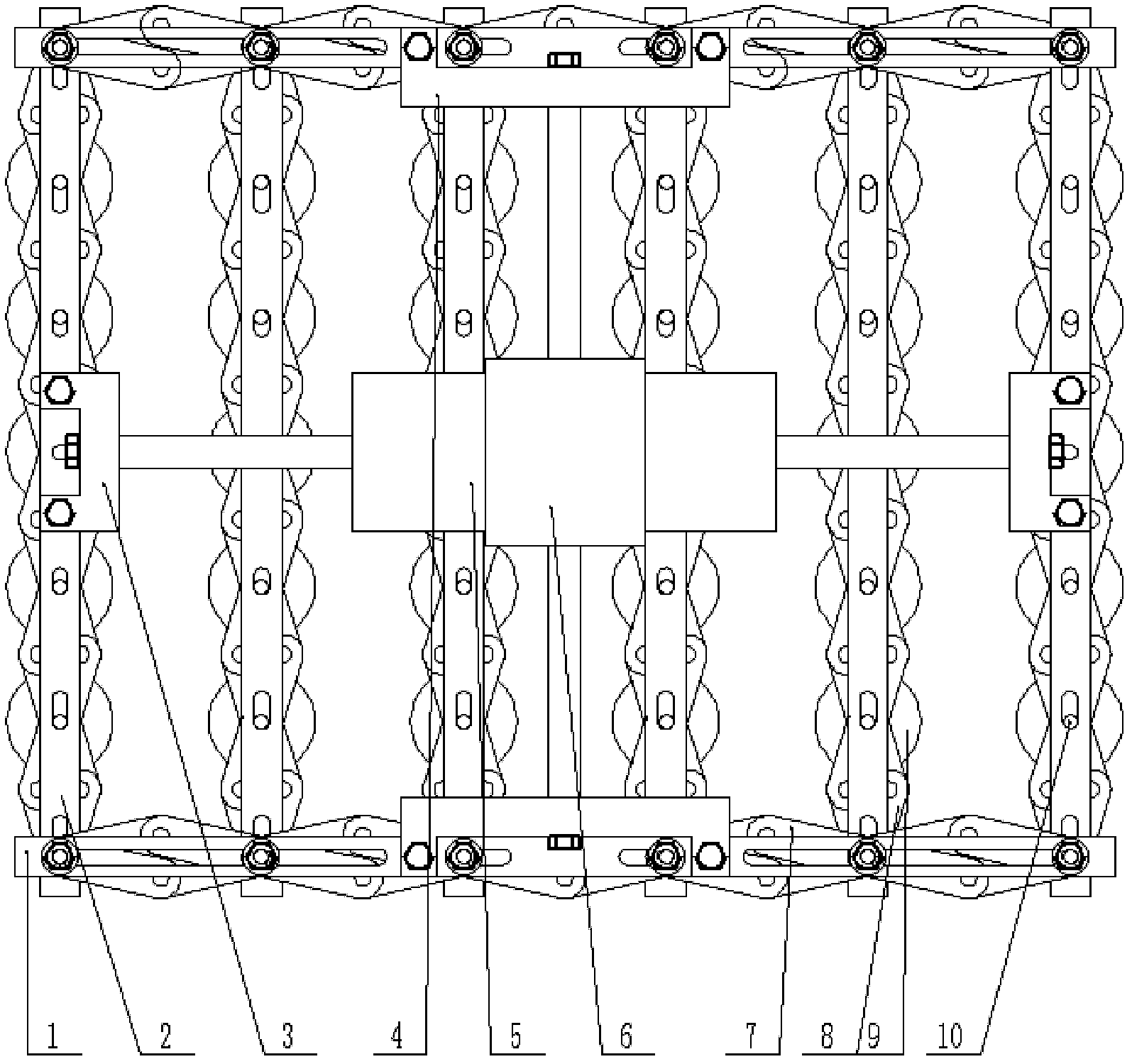

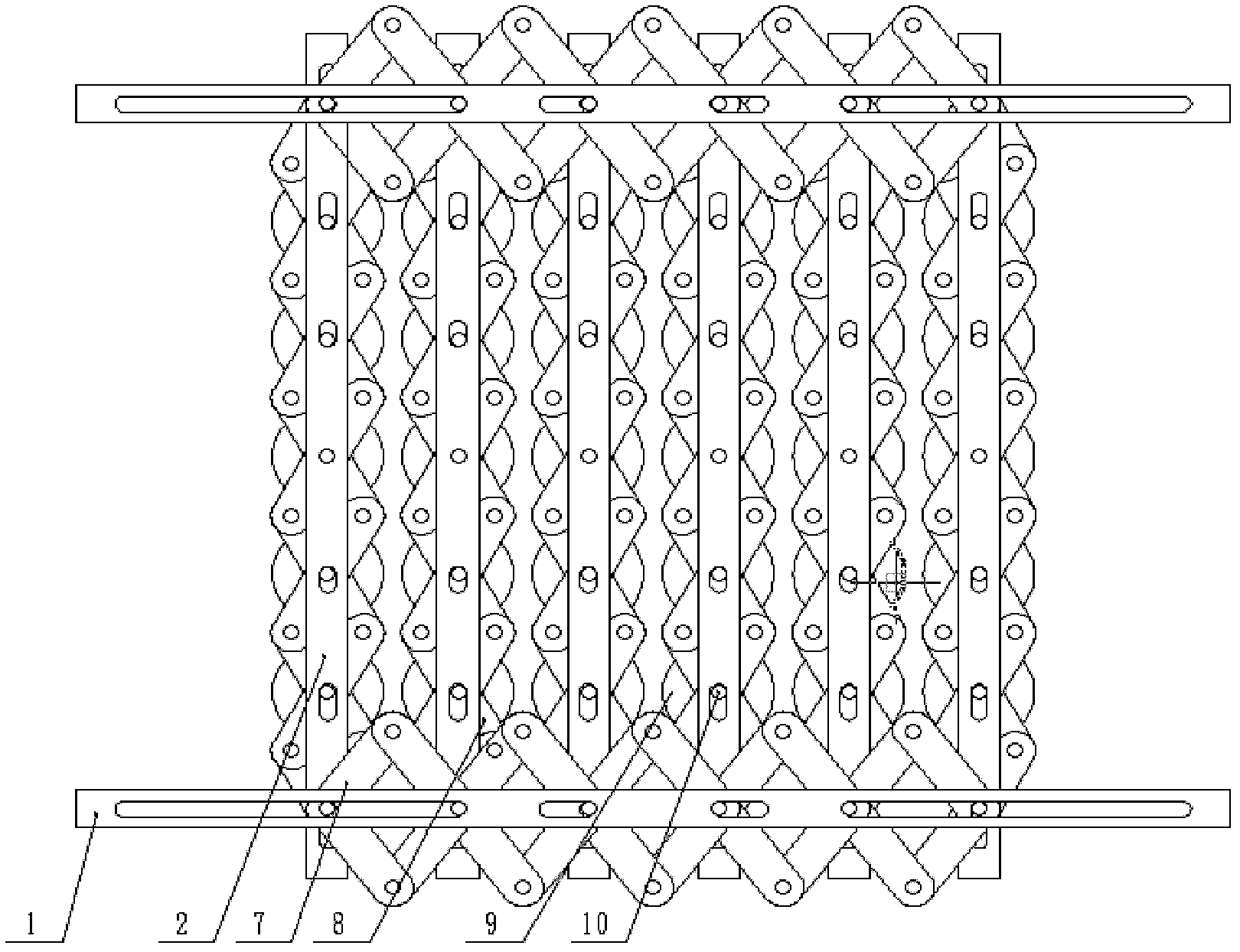

[0022] Attached below Figure 1-5 The structural principle and working principle of the present invention are further described in detail by absorbing 30 eggs at a time. In actual production, the number of egg absorbers can be designed according to actual needs.

[0023] The top view of the overall shrinkage state of the egg feeding device of the present invention is as follows figure 1 As shown, the top view of the overall extended state is as follows figure 2 shown. Including telescopic module, claw module and suction module;

[0024] 1) Telescopic module: telescopic module includes X-axis push block 3, Y-axis push block 4, X-direction cylinder 5, Y-direction cylinder 6; X, Y-direction cylinder 5, 6 bolts and X, Y-axis push blocks 3, 4 Connected; the X and Y axis push blocks 3 and 4 are pushed by the X and Y direction cylinders 5 and 6 to control the expansion and contraction of the claw plate at equal intervals in the X-Y direction, which can respectively adapt to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com