Patents

Literature

34results about How to "Easy to fully automate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

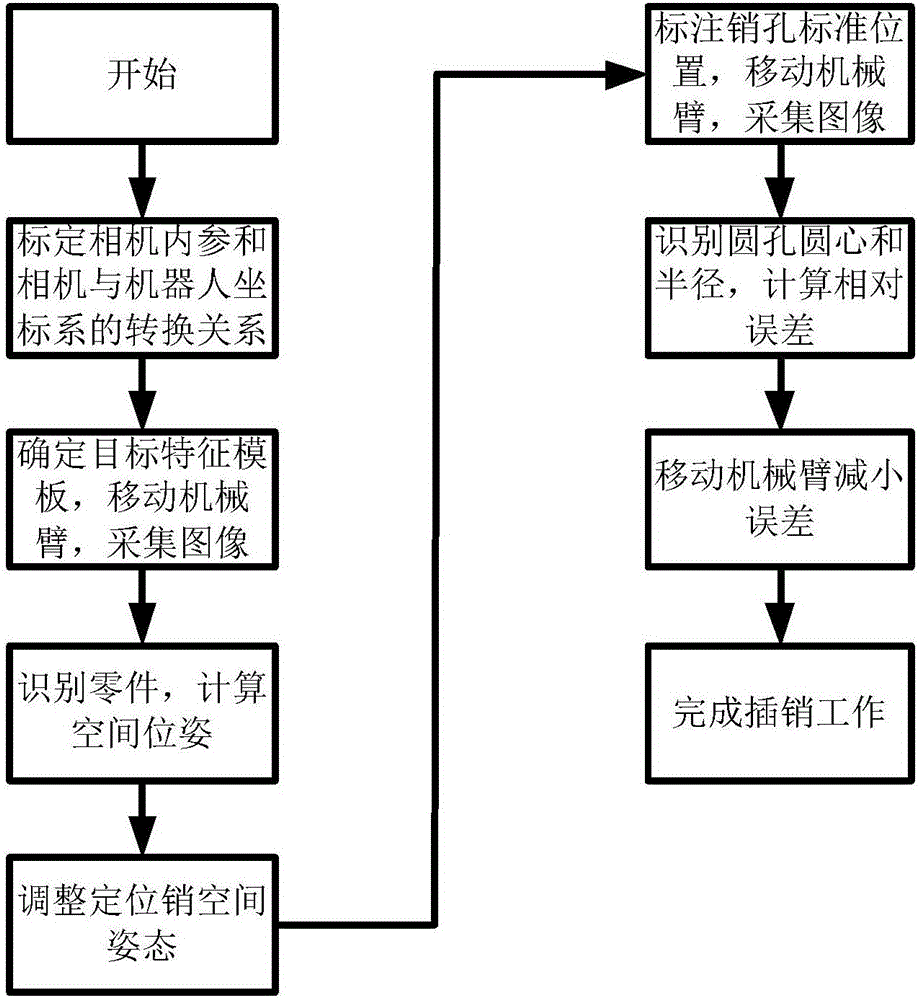

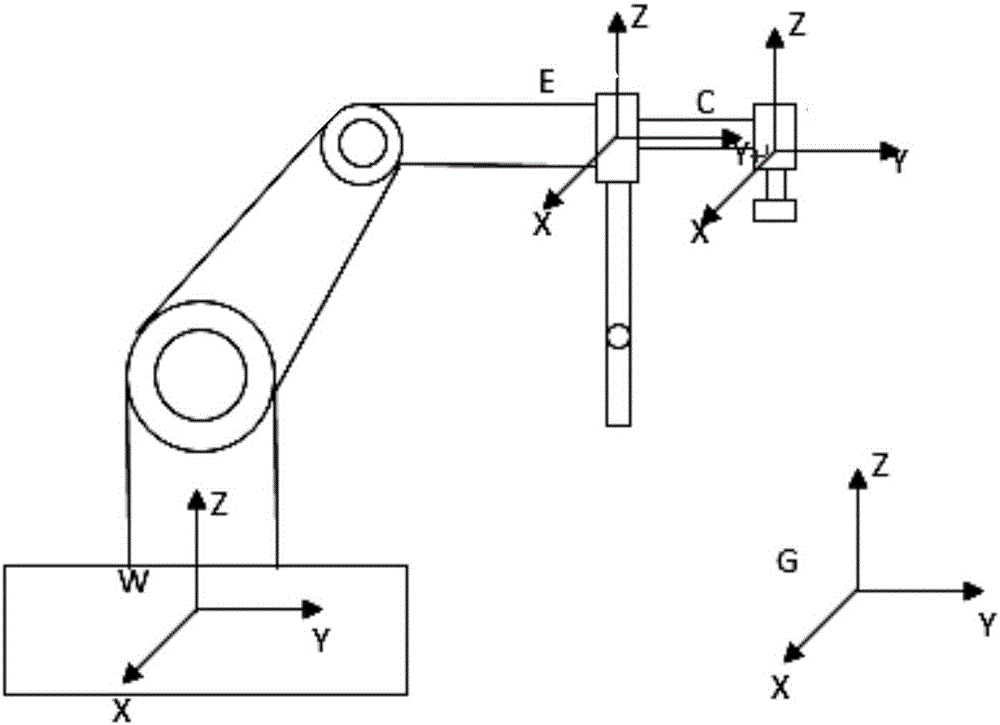

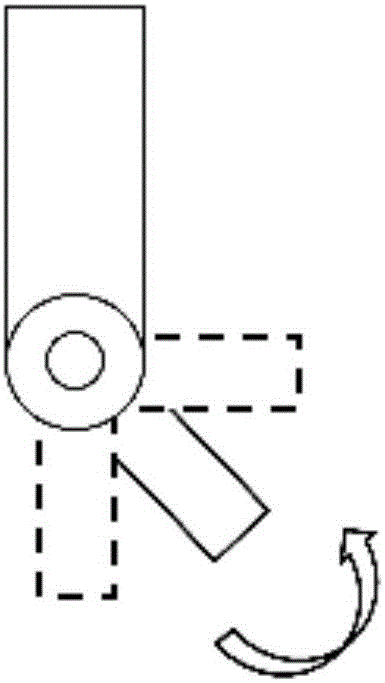

Industrial robot automatic pin hole assembling method based on visual guidance

ActiveCN106182004APrecise estimation of poseGuaranteed costProgramme-controlled manipulatorWork taskVision based

The invention provides an industrial robot automatic pin hole assembling method based on visual guidance. A CCD industrial camera is used for serving as a visual system, and through adoption of a positioning pin outline recognition algorithm and a positioning algorithm, recognition, positioning, grabbing, hole inserting and other work tasks of a positioning pin are completed. The posture of the positioning pin in the space can be precisely estimated, and the precision is high. Image matching and recognition are both based on the outline, implementation is easy, and real-time performance is good. Full automation from part grabbing to pin inserting work is achieved based on a monocular hand and eye mechanical arm, meanwhile, hardware cost is kept, and the work efficiency and quality of a robot are improved.

Owner:SHANGHAI JIAO TONG UNIV

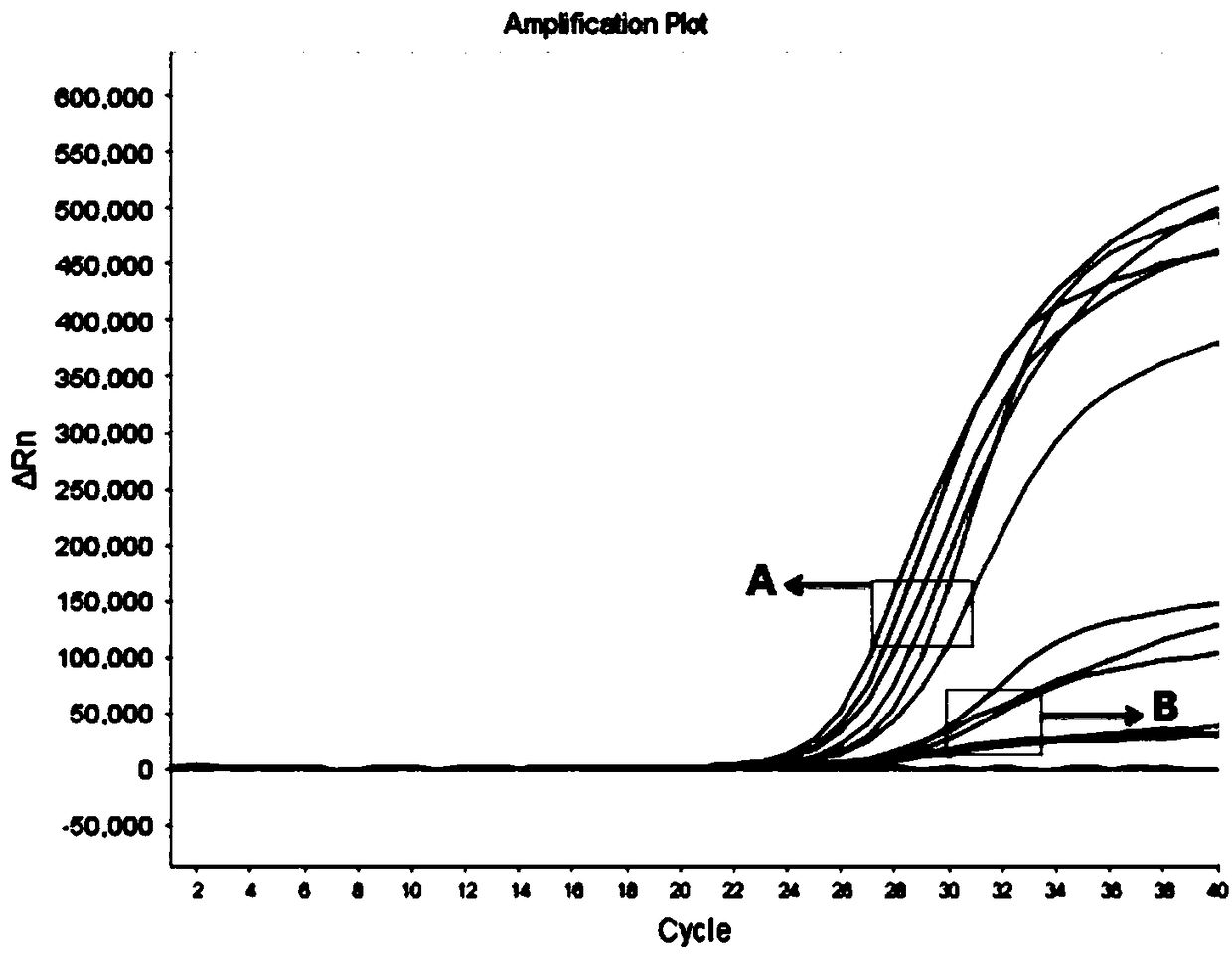

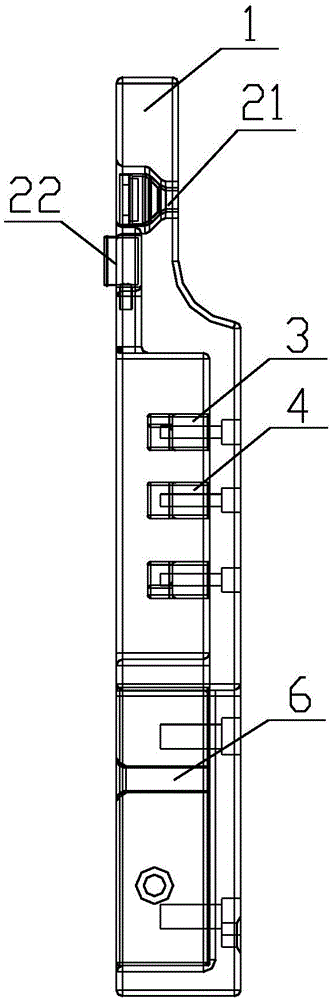

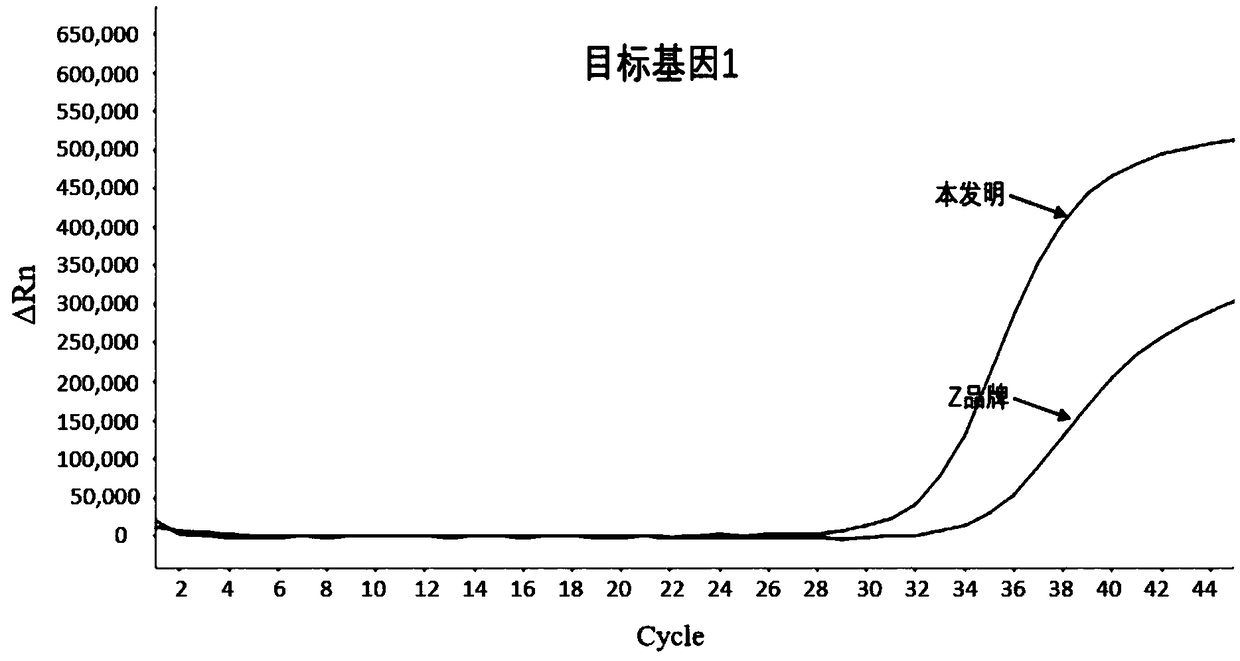

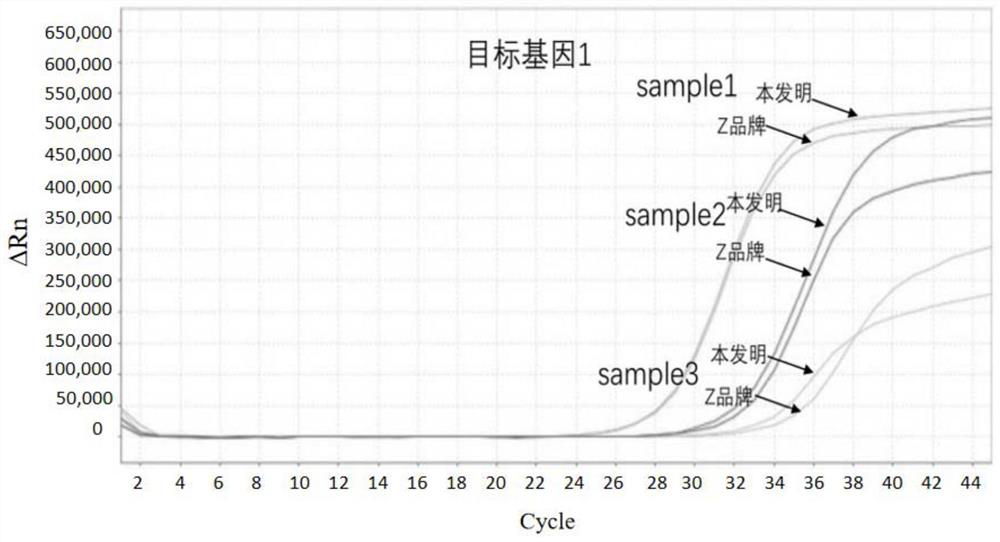

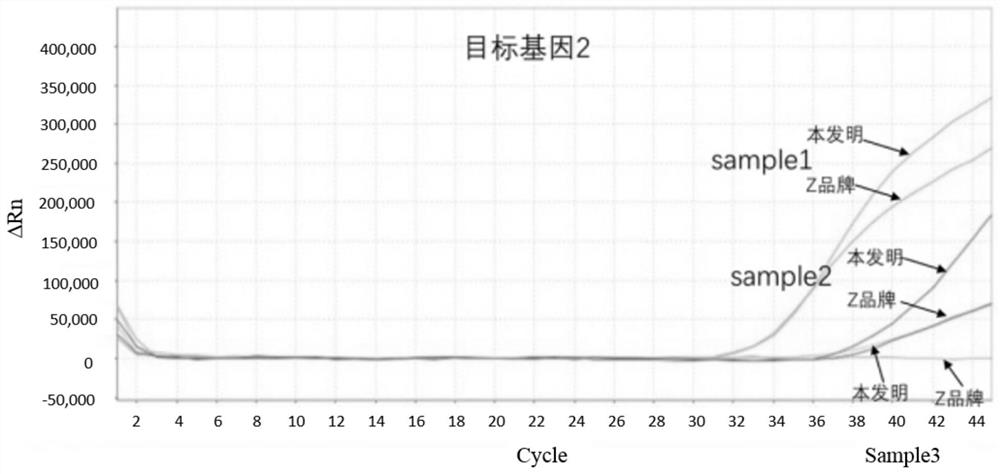

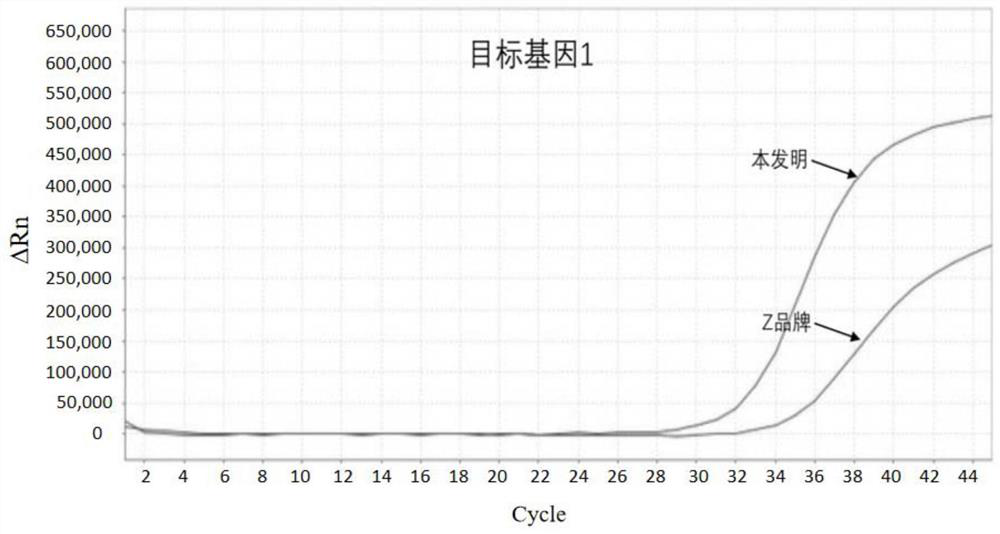

Magnetic bead process nucleic acid extraction and transformation kit, and using method thereof

InactiveCN109022417AAvoid wastingHigh purityMicrobiological testing/measurementDNA preparationLysisMagnetic bead

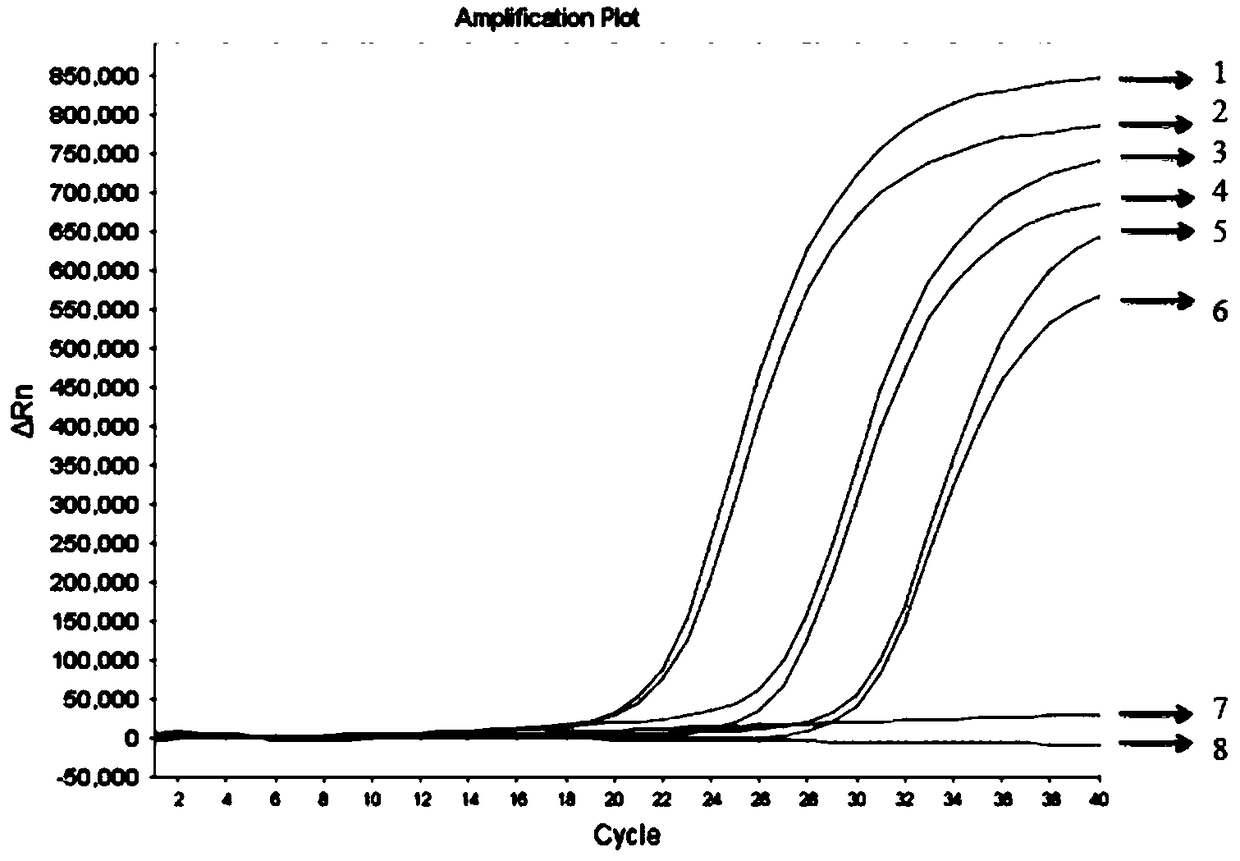

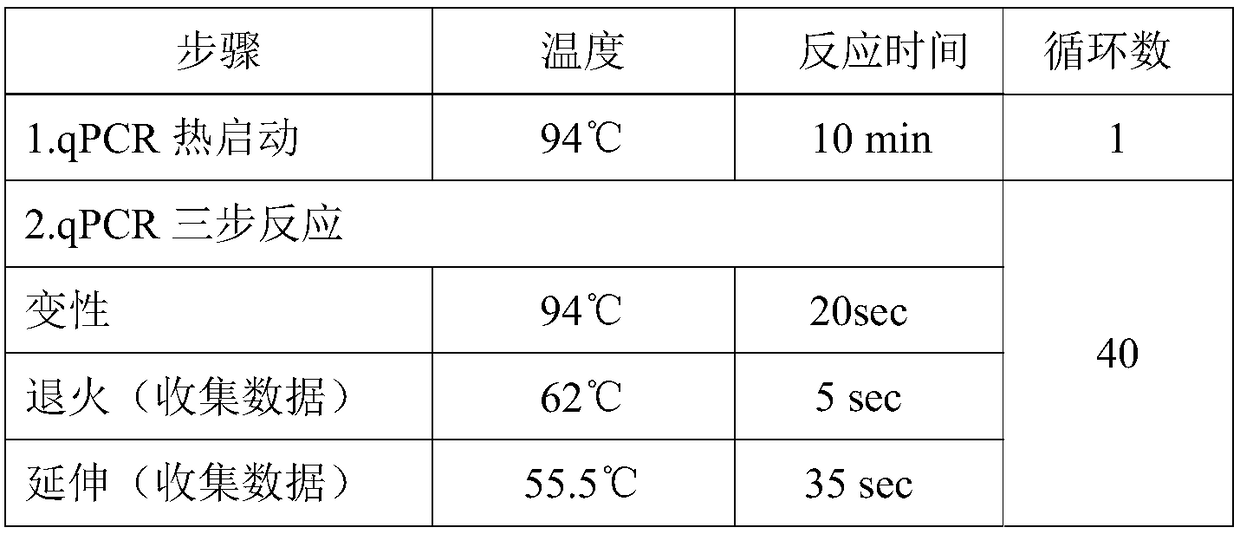

The invention provides a magnetic bead process nucleic acid extraction and transformation kit, and a using method thereof. The kit includes a lysate, a protease K, a magnetic bead solution, a transforamtion reagent, a nucleic acid protection agent, a binding solution, a washing solution I, a washing solution II and an eluent. The using method of the kit includes the following steps: (1) lysis; (2)transformation; (3) layering; (4) binding; (5) primary washing; (6) secondary washing; (7) drying; and 8) elution. The kit and the using method thereby can complete the transformation while achievingautomatic extraction of nucleic acid from a sample. The sample is lysed, releases the nucleic acid, and then begins to transform, the nucleic acid is separated from proteins by the binding solution after the transformation is completed, the methylated nucleic acid is purified by a magnetic bead process, and a pre-denaturation step in subsequent qPCR detection of the sample is used to replace a previously omitted sulfo group removal step, so a purification process in the original nucleic acid extraction step is omitted in the entire extraction and transformation process.

Owner:SUREXAM BIO TECH

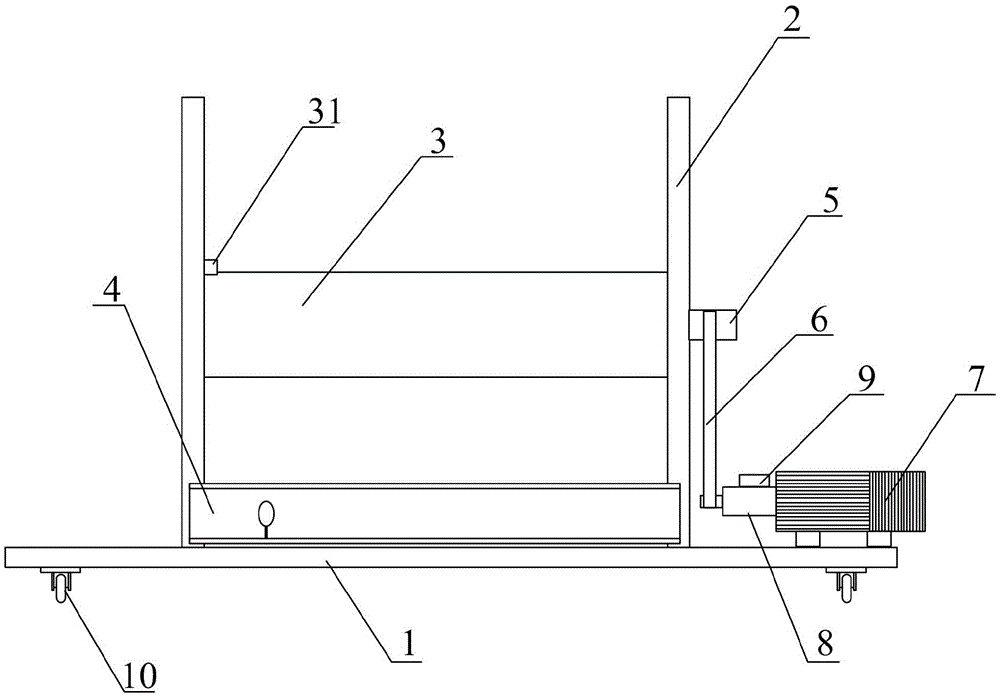

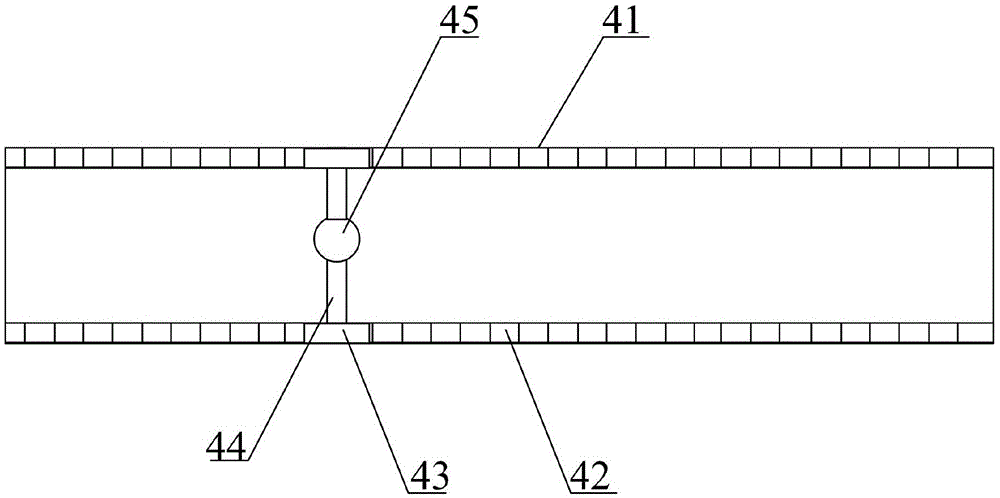

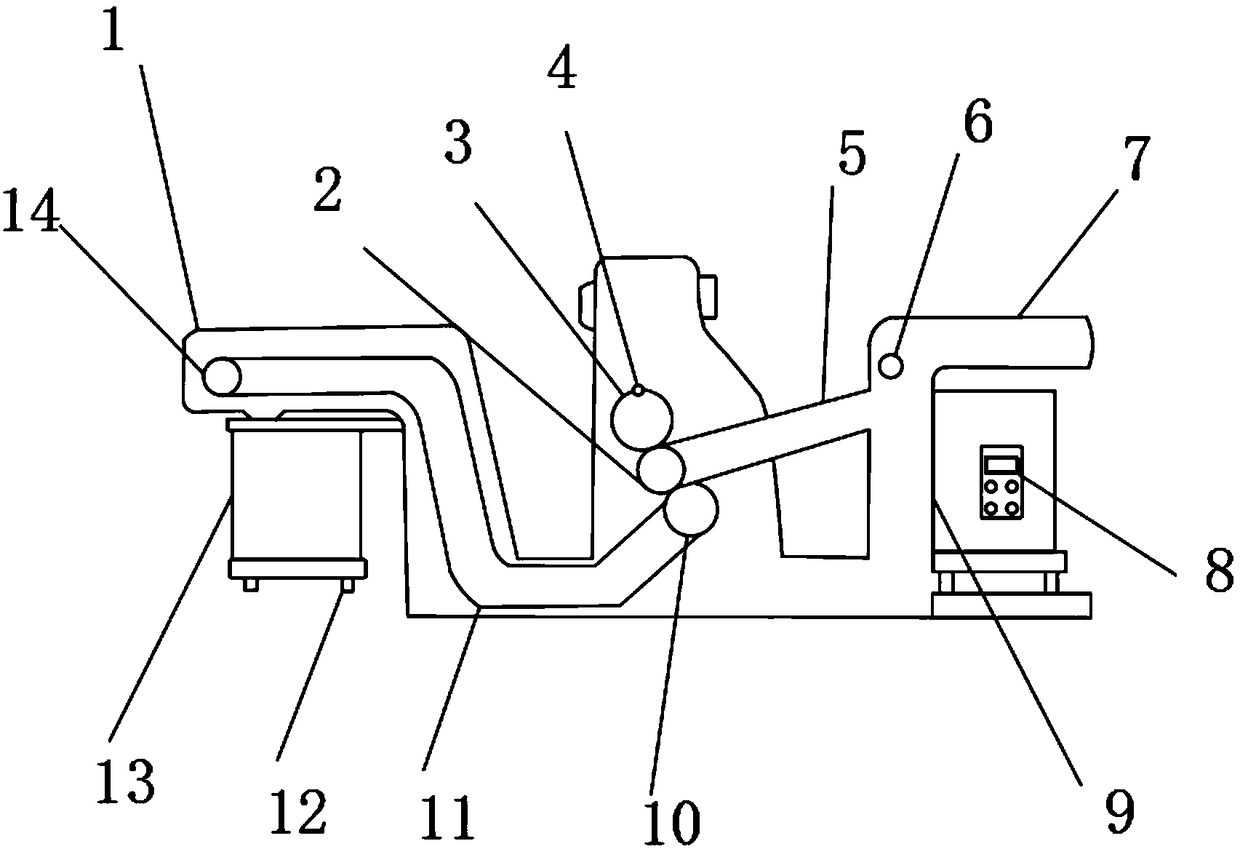

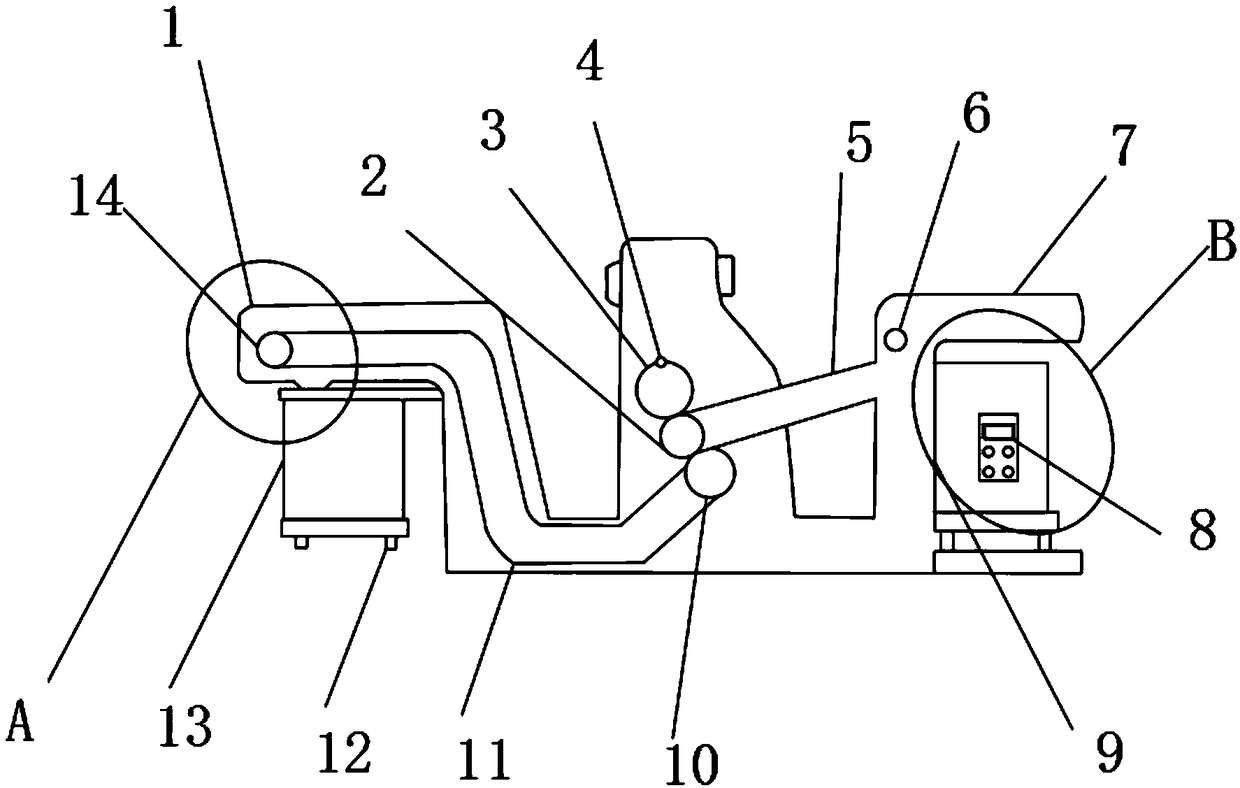

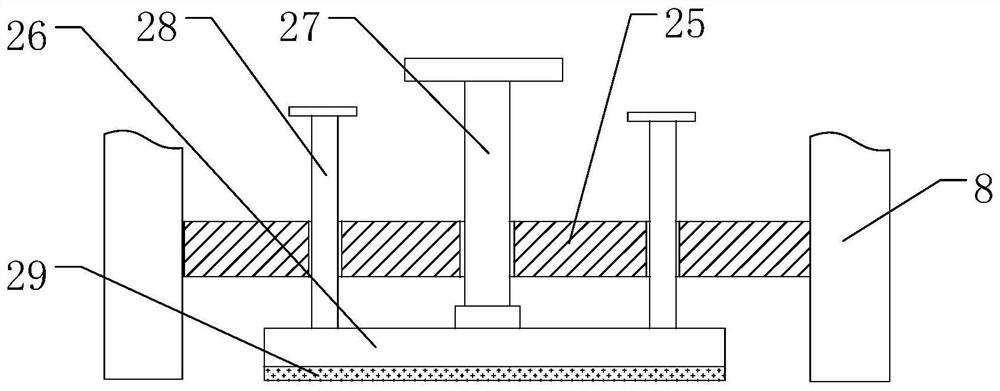

Intelligent electric wire winding device

InactiveCN105645179APrevents over-winding or vacancyFully automated preventionFilament handlingEngineeringConductor Coil

The invention provides an intelligent electric wire winding device. The intelligent electric wire winding device comprises a base, baffles, a wire coil rotation roller, a wire winder, a rotating shaft, a conveying belt, a motor, a speed reducer, a controller and rolling wheels, wherein the baffles are fixedly installed on the two sides of the upper part of the base and support the wire coil rotation roller; the wire winder is arranged at the front end of the wire coil rotation roller; the rotating shaft is coaxially connected to the wire coil rotation roller and is connected to the speed reducer through the conveying belt; the conveying belt is connected to the motor; the controller is installed at the upper part of the speed reducer; the wire winder comprises an installation rack, sliding rails, sliding blocks, a connector and wire passing holes, wherein the sliding rails are installed on the installation rack, the sliding blocks are installed in the sliding rails, and the connector is connected to the sliding blocks and the wire passing holes. According to the intelligent electric wire winding device, by arranging the motor and the controller, wire cables can be automatically wound, the non-uniform and incompact winding problems of the wire cables are prevented, the manpower is greatly saved, and the wire winding quality is improved.

Owner:STATE GRID CORP OF CHINA +1

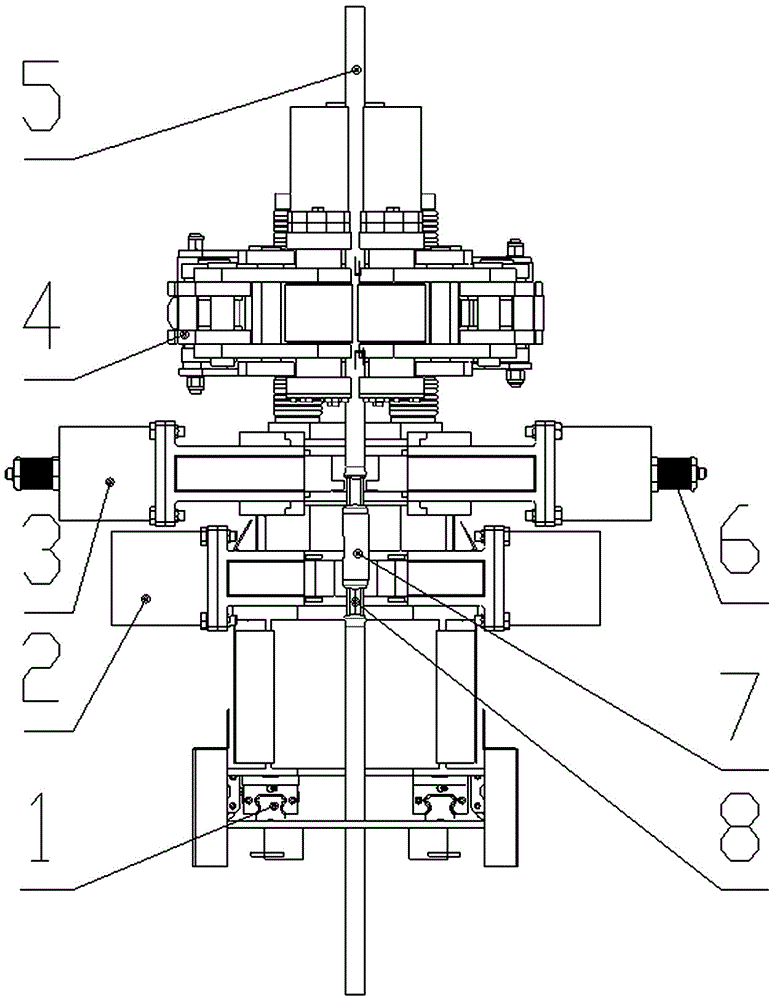

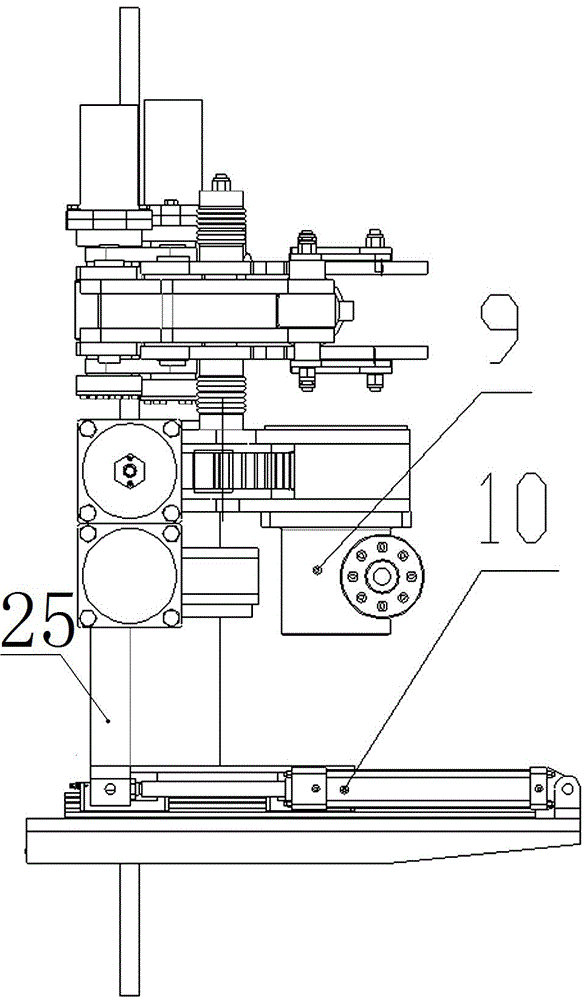

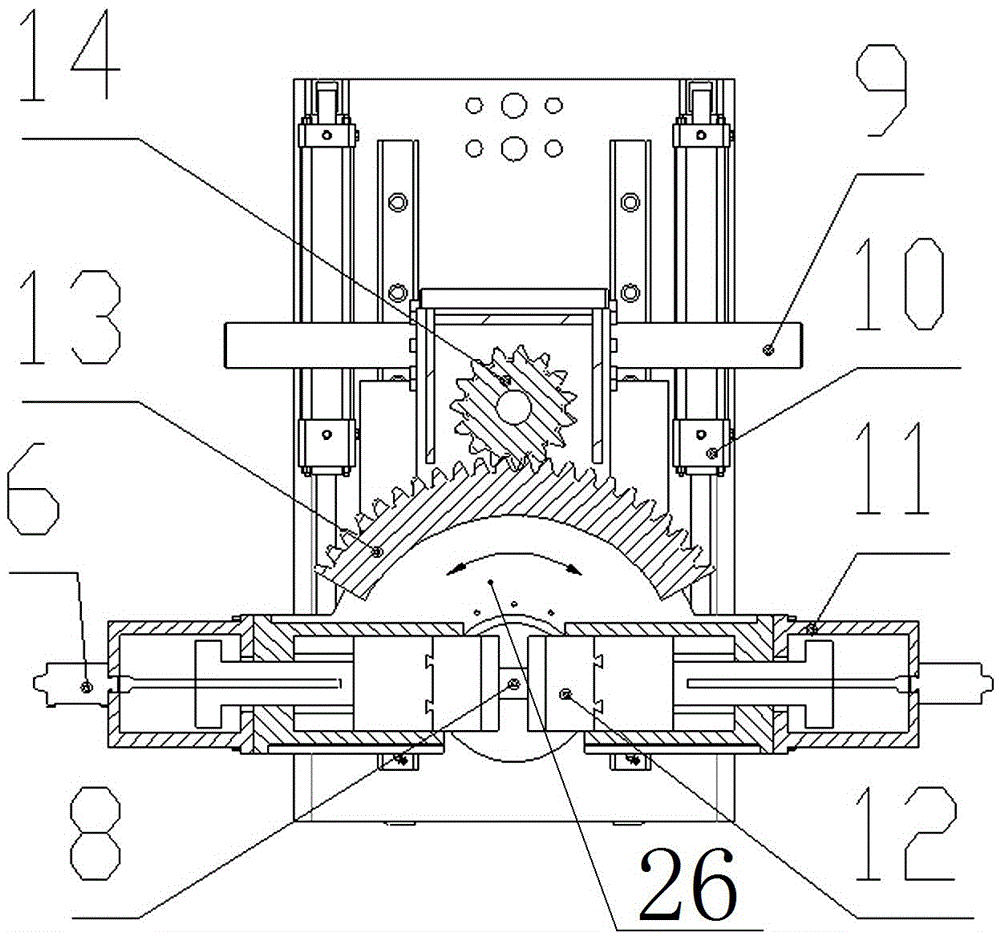

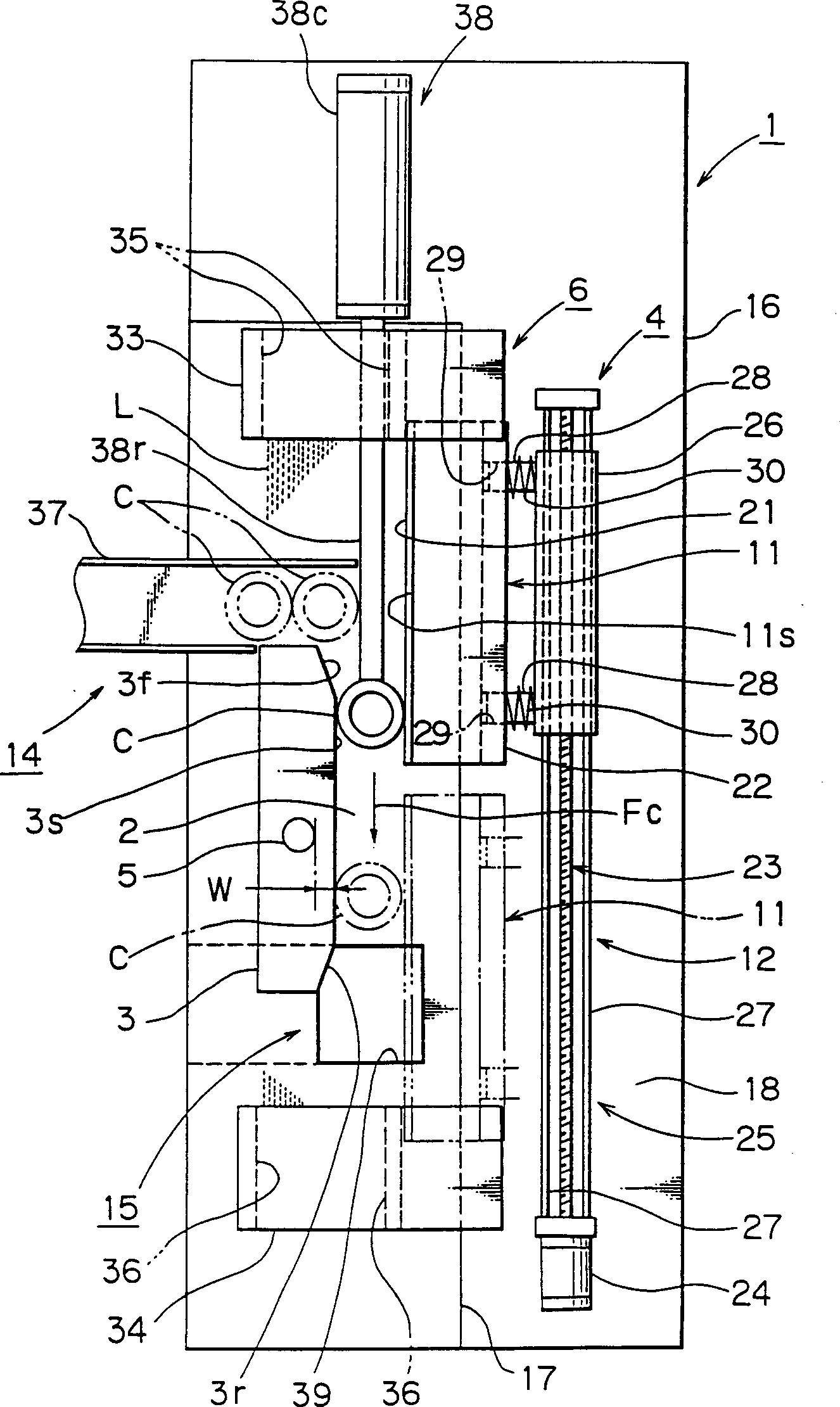

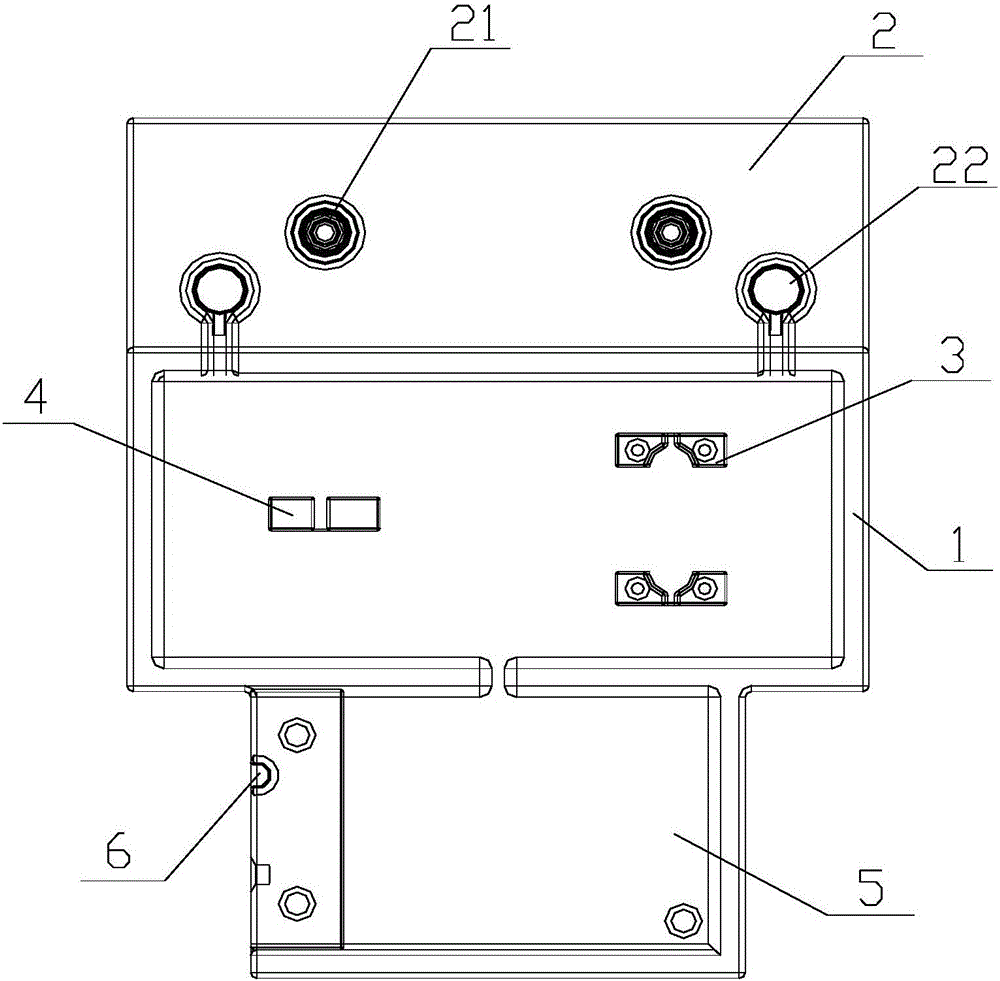

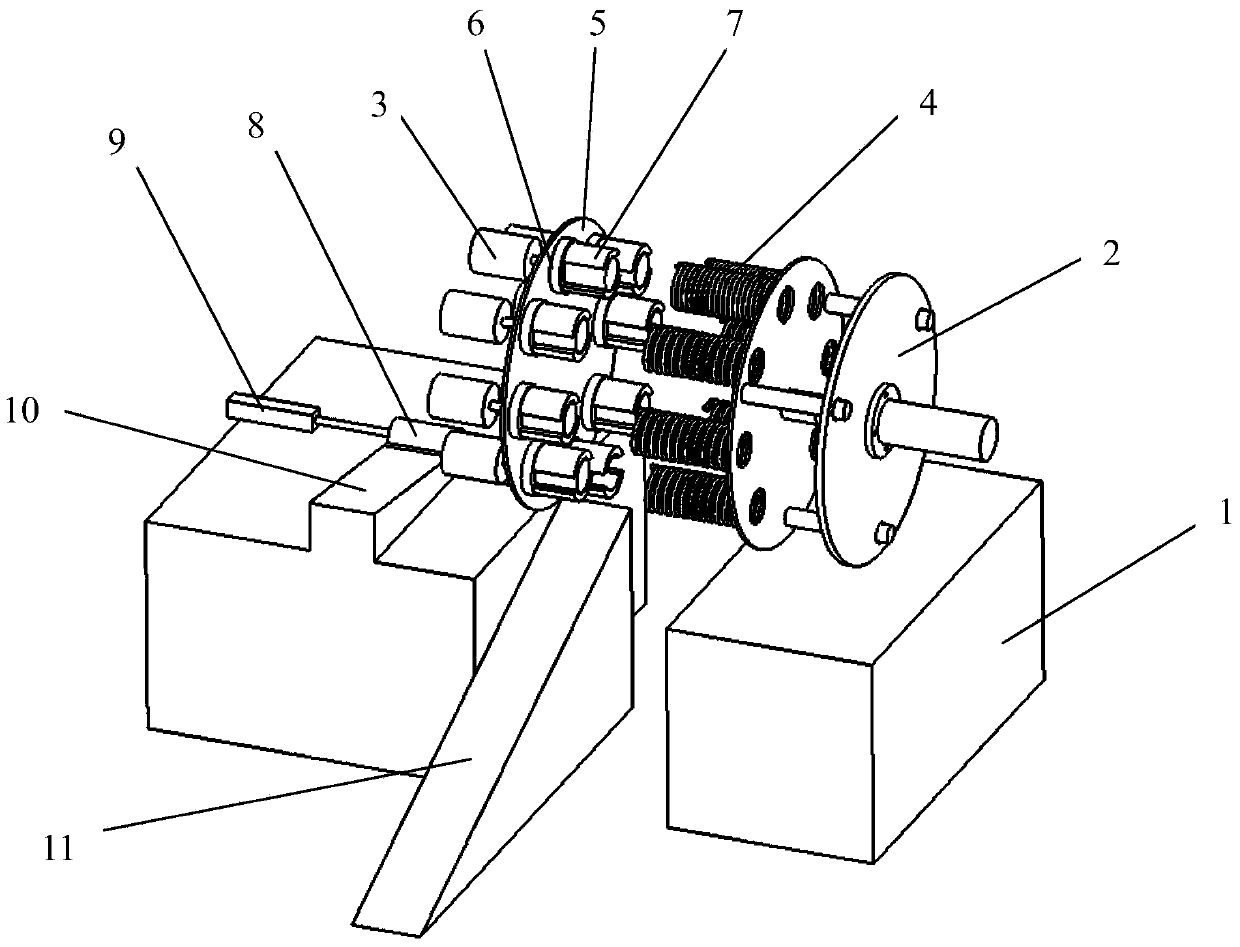

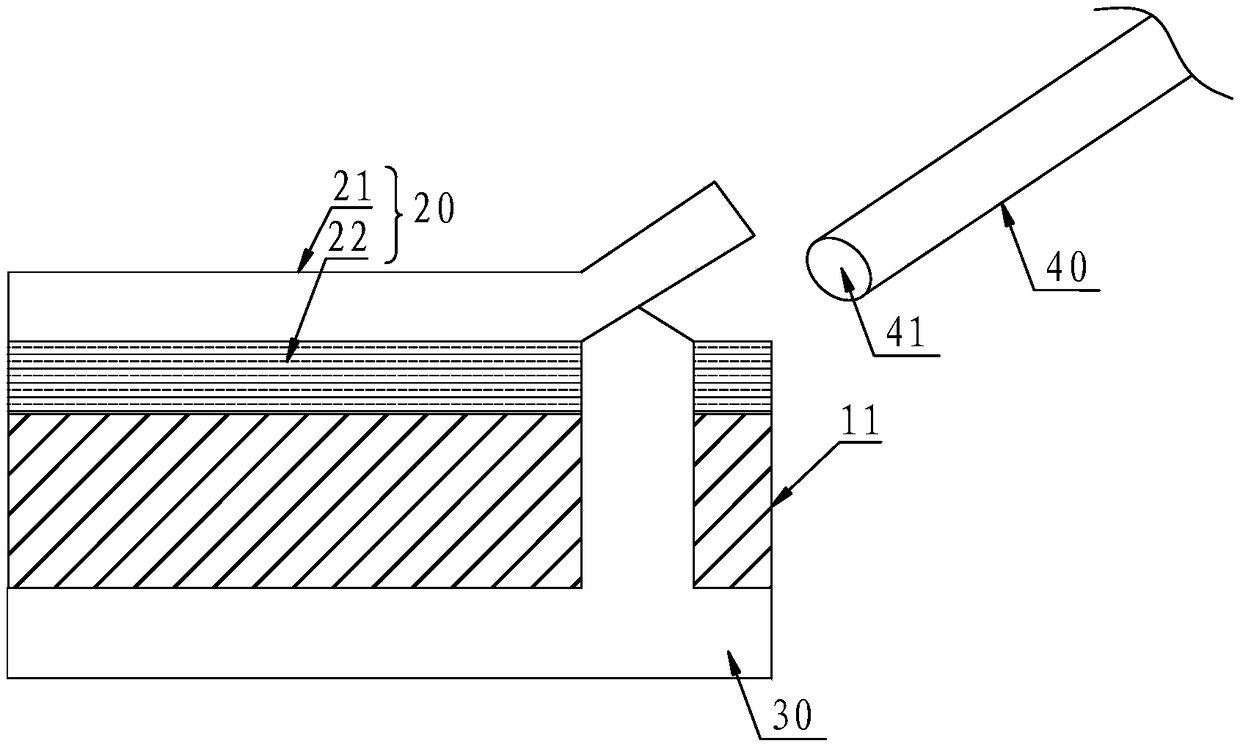

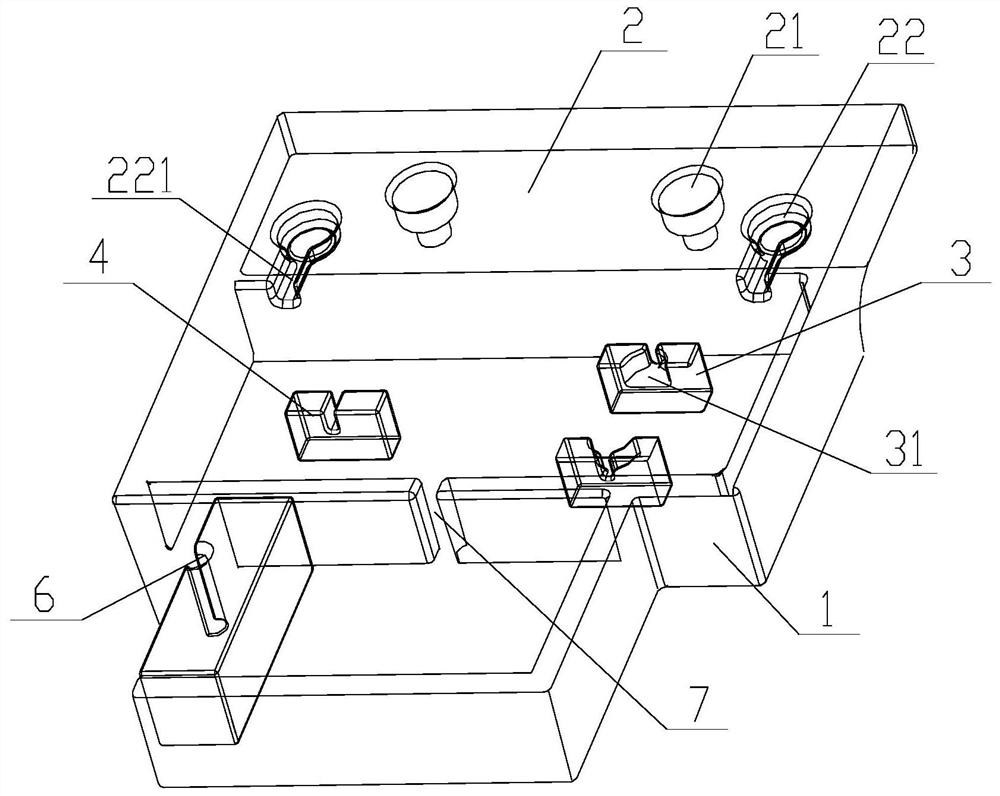

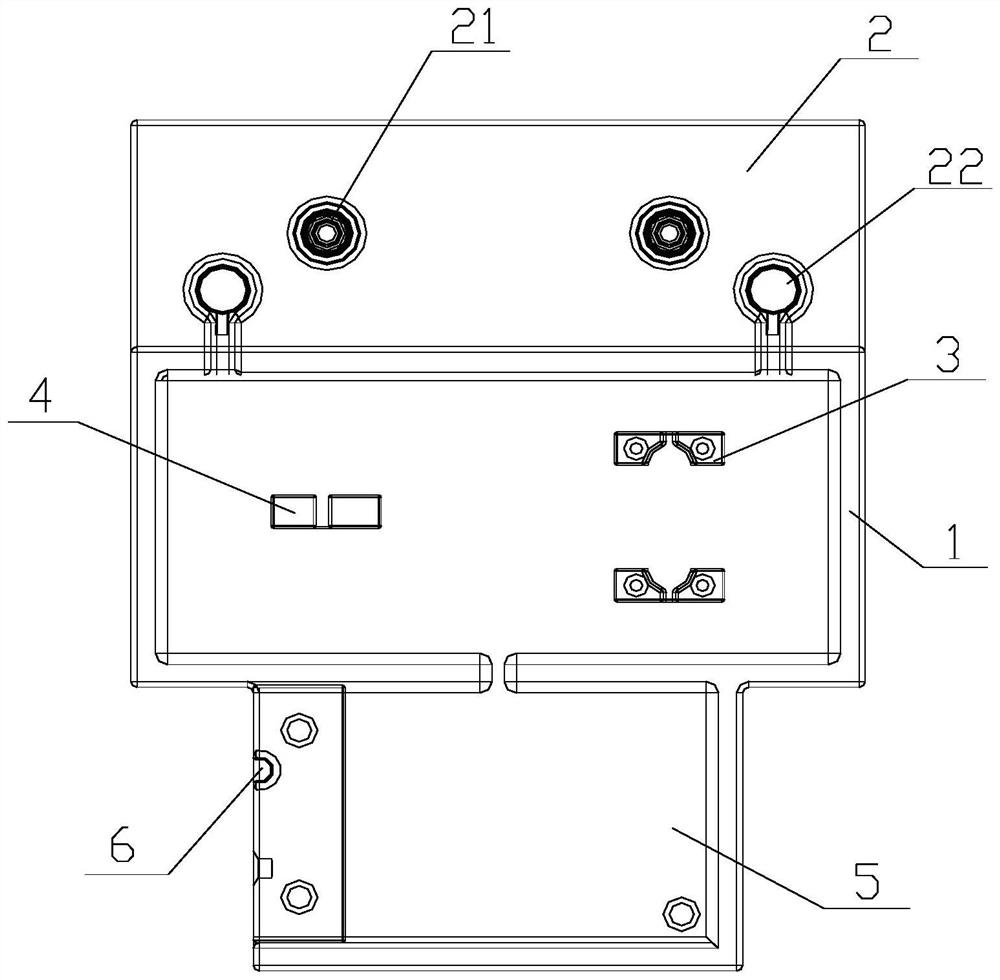

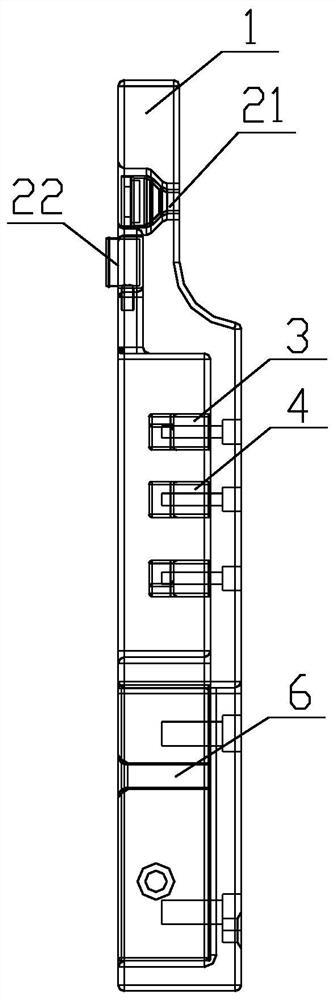

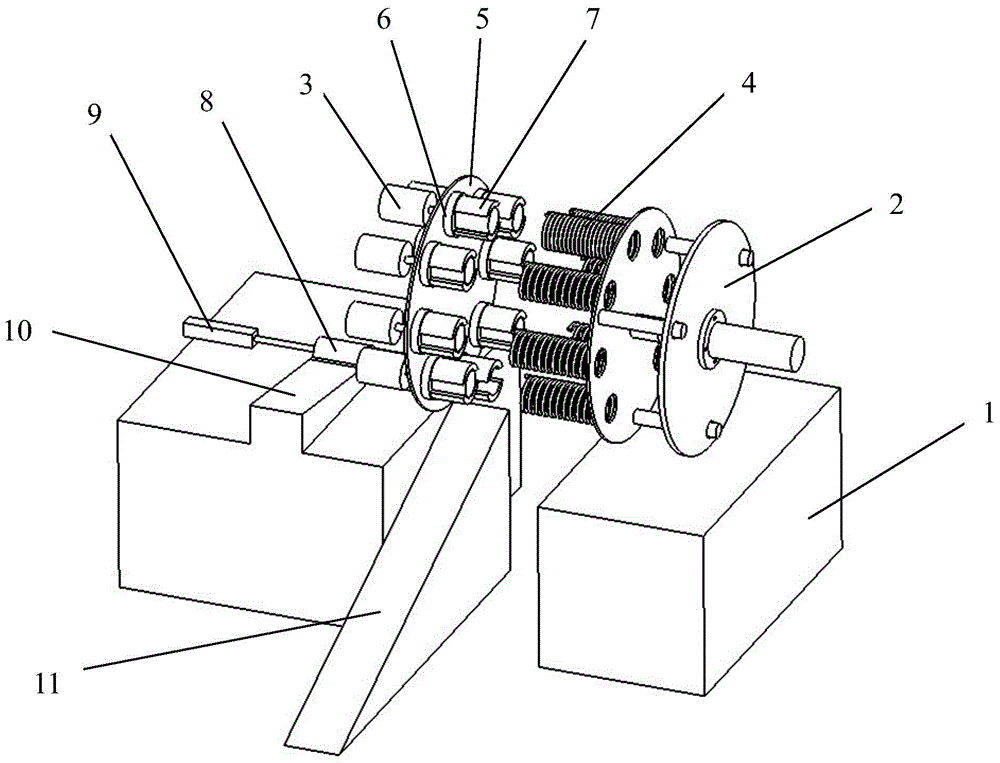

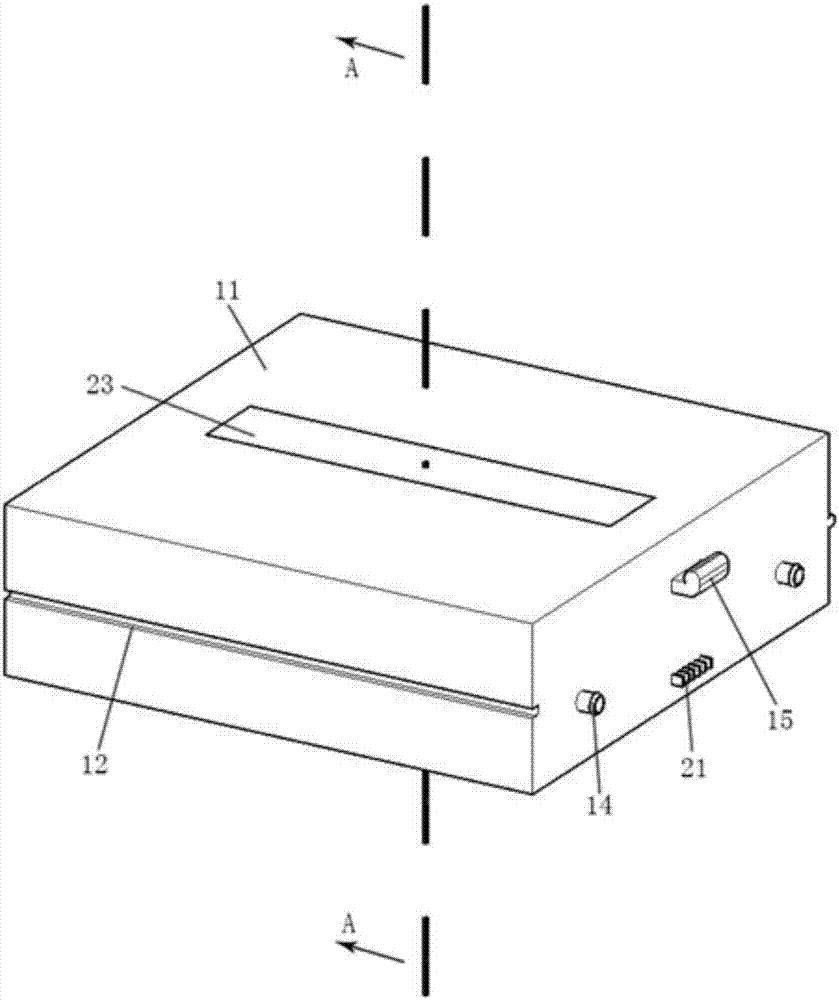

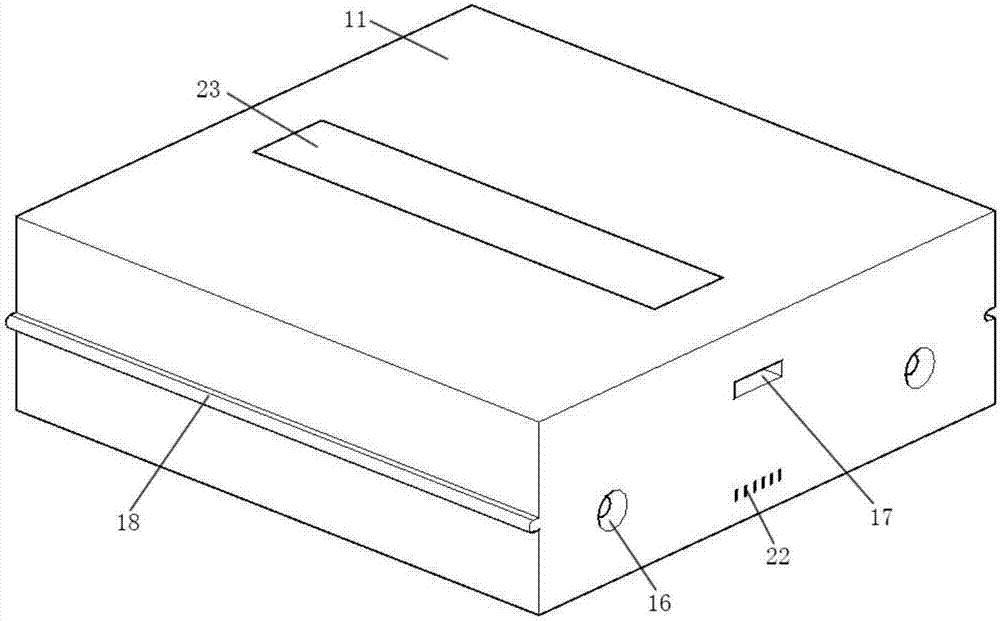

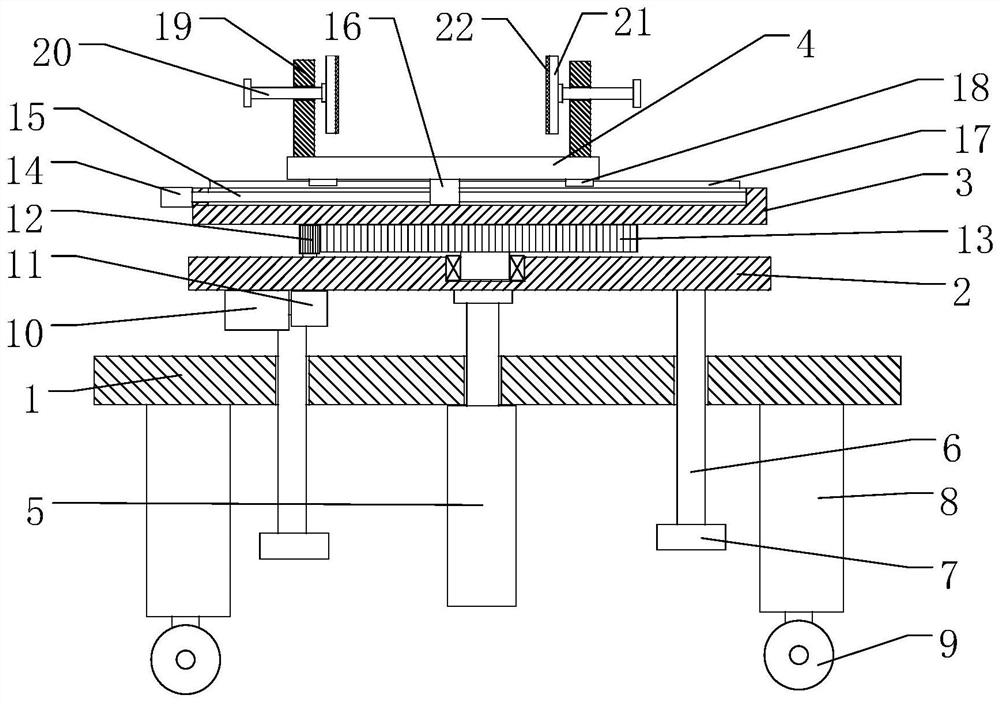

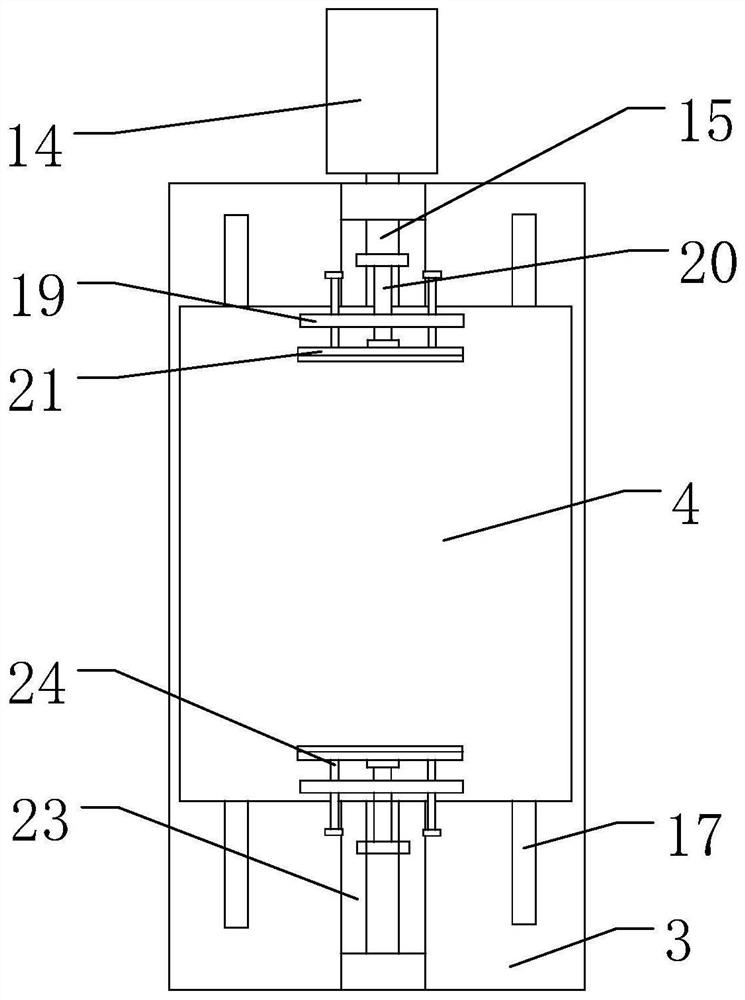

Floating type automatic sucker rod screwing on and off device

ActiveCN105545231AEasy to fully automatePromote intelligent developmentDrilling rodsDrilling casingsCouplingModular design

A floating type automatic sucker rod screwing on and off device comprises a support, a back-up wrench, a moving wrench and a rotary wrench. The support is sequentially and coaxially provided with the back-up wrench, the moving wrench and the rotary wrench from bottom to top. The back-up wrench is used for clamping a coupling of a first sucker rod and providing reactive torque needed in screwing on and off. The moving wrench is used for clamping the wrench part of a second sucker rod and achieving tightening buckling and tight buckling. The rotary wrench is used for screwing off and screwing on the sucker rods. The floating type automatic sucker rod screwing on and off device has the advantages that the blank of the floating type automatic sucker rod screwing on and off device is filled in, full-automatic and intelligent development of a drilling rig is facilitated, the number of drilling operating personnel is reduced, the operating personnel are far away from a well mouth, the injuries of occurring accidents to the operating personnel are reduced, the integration degree is high, and modular design of downstream equipment is facilitated.

Owner:SHANDONG SHENGLI PETROLEUM EQUIP IND TECH RES INST

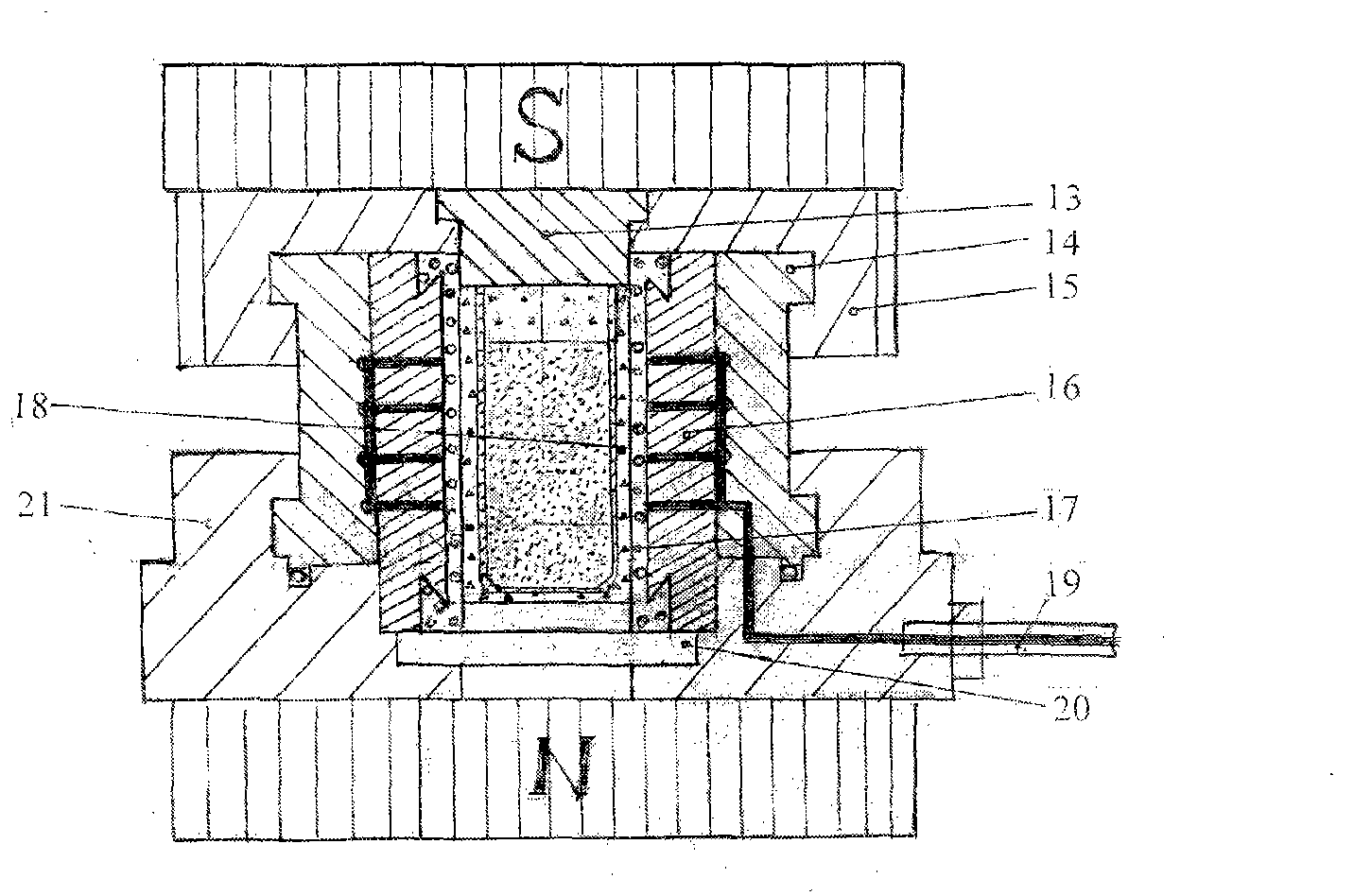

Technology and device for forming dry bag quick isostatic pressing in oriented magnetic fields

InactiveCN103878368AImprove automationIncrease the level of mechanizationInorganic material magnetismInductances/transformers/magnets manufactureResource utilizationMagnetic poles

The invention belongs to the field of technologies for manufacturing magnetic materials, and provides a technology and a device for forming dry bag quick isostatic pressing in oriented magnetic fields. The technology and the device have the advantages that an oriented magnetic field technology is ingeniously and organically combined with the technology and the device for forming dry bag isostatic pressing by the aid of a novel design concept, so that dry bag isostatic pressing can be formed in the oriented magnetic fields which have optional directions and optional magnetic field intensities by the aid of the novel technology and the novel device; orientation degrees of products can be obviously upgraded; two necessary working procedures in existing neodymium, iron and boron magnet production can be combined with each other to form one working procedure by the novel technology and the novel device, and the automation and mechanization levels are high; powder is not in contact with pressing blanks and oil in production procedures, and accordingly a latex sheath for binding the corresponding pressing blank can be omitted; the pressing blanks are quite uniform in density distribution and internal stress distribution; the pressing blanks can be machined, and original powder can be recycled; single-hole and multi-hole thin-walled pipes, sleeves and multi-magnetic-pole products which are heavy and are in complicated shapes or have large length-diameter (L / d) ratios can be produced by the aid of the technology and the device, the rare earth mineral resource utilization rate can be greatly increased, and the neodymium, iron and boron magnet industrial production level of China can be upgraded to the world leading level.

Owner:吴庆华 +2

Egg feeding device for egg production line

InactiveCN102616565AReduce labor costsReduce manual labor intensityConveyor partsEngineeringActuator

The invention relates to an egg feeding device for an egg production line and belongs to the technical field of food raw material sorting. The egg feeding device comprises a sucking disc and a valve body connected with the sucking disc through a guide pipe, wherein the sucking disc is in threaded connection with a hollow pin and is mounted on a jaw chuck; an air cylinder shrinks, the jaw chuck shrinks along a guide rail XY so as to reach the size of an egg tray, suck the eggs and lift the eggs to the production line; and the air cylinder stretches, the jaw chuck stretches along the guide rail XY, so that the requirement on the space size of a conveying roller in the production line is achieved and the eggs are put down. The egg feeding device disclosed by the invention is simple in structure, convenient in use, safe and reliable and is suitable for eggs of various poultries. The egg feeding device can be used as a tail end executor of an egg sucking and feeding manipulator, can be used as a manipulator terminal under the later allowable conditions and provides convenience for full automation of the egg production line.

Owner:镇江格瑞特仪器设备有限责任公司

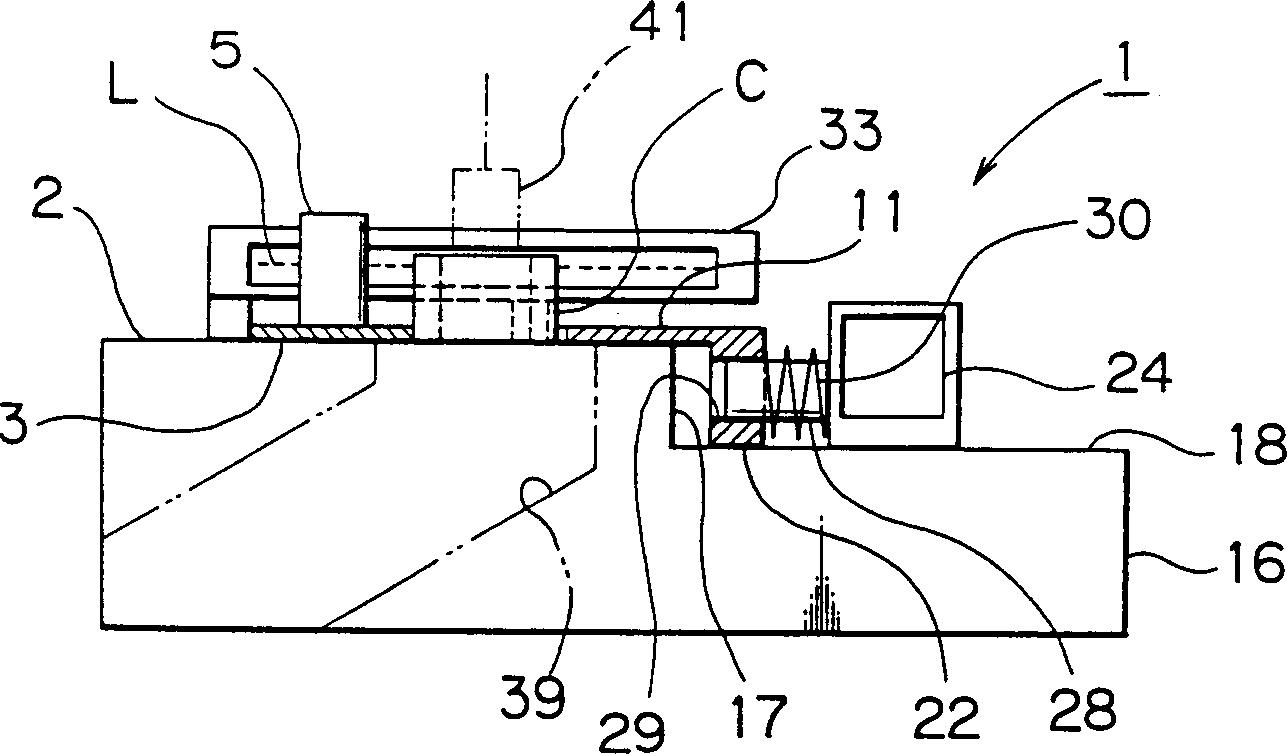

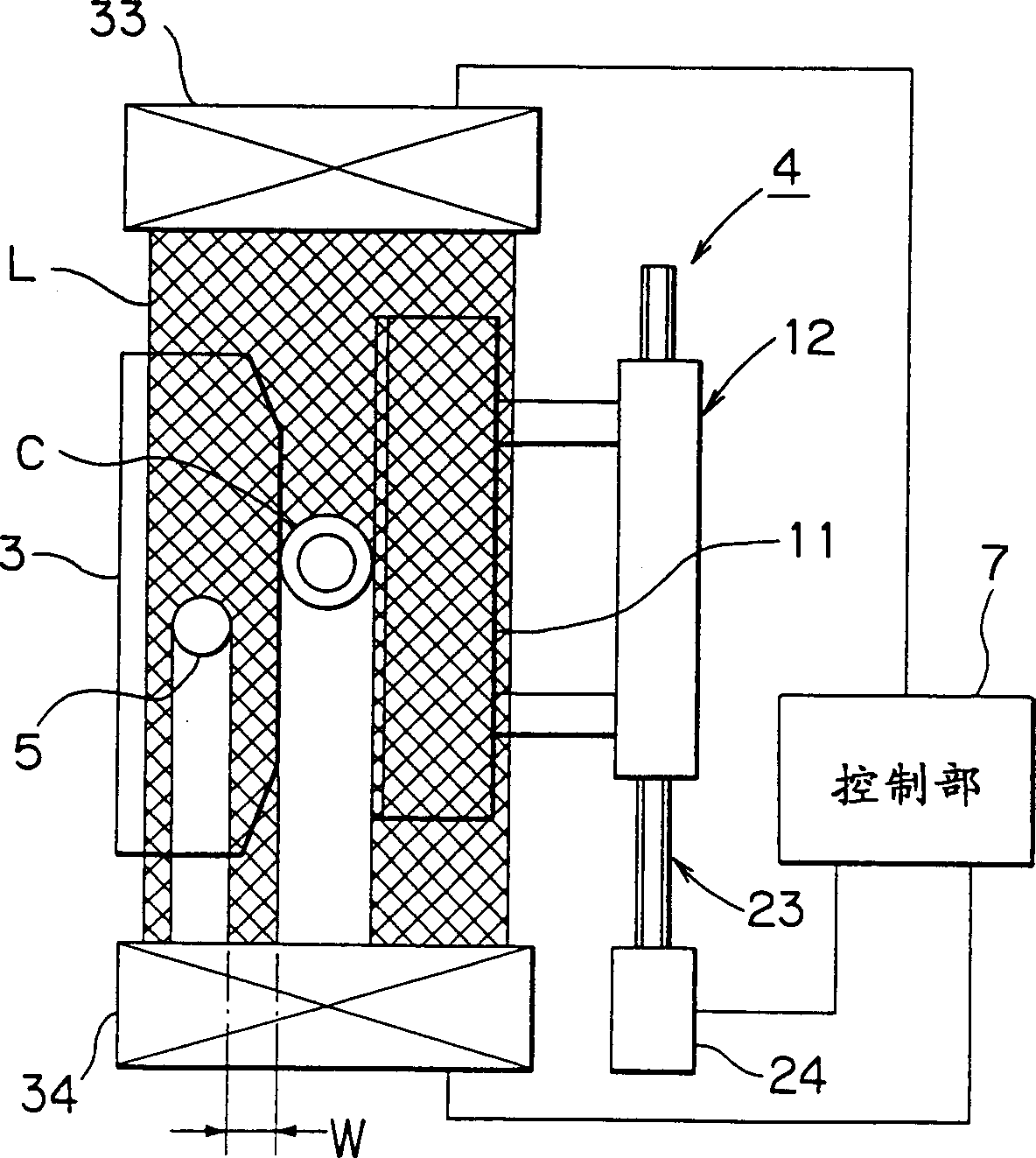

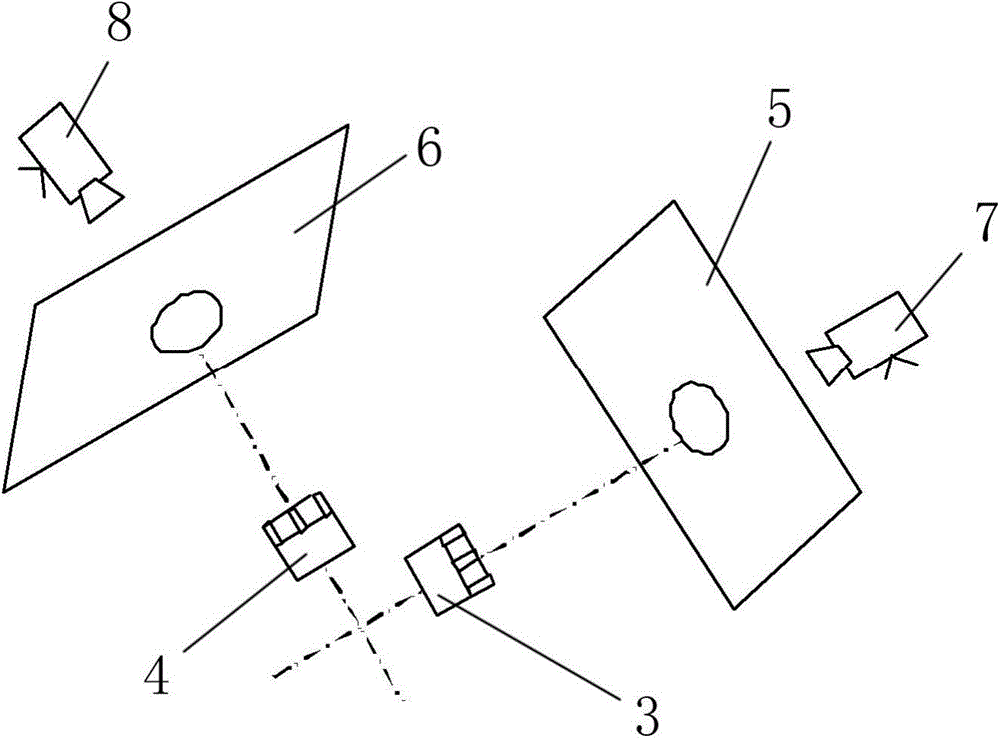

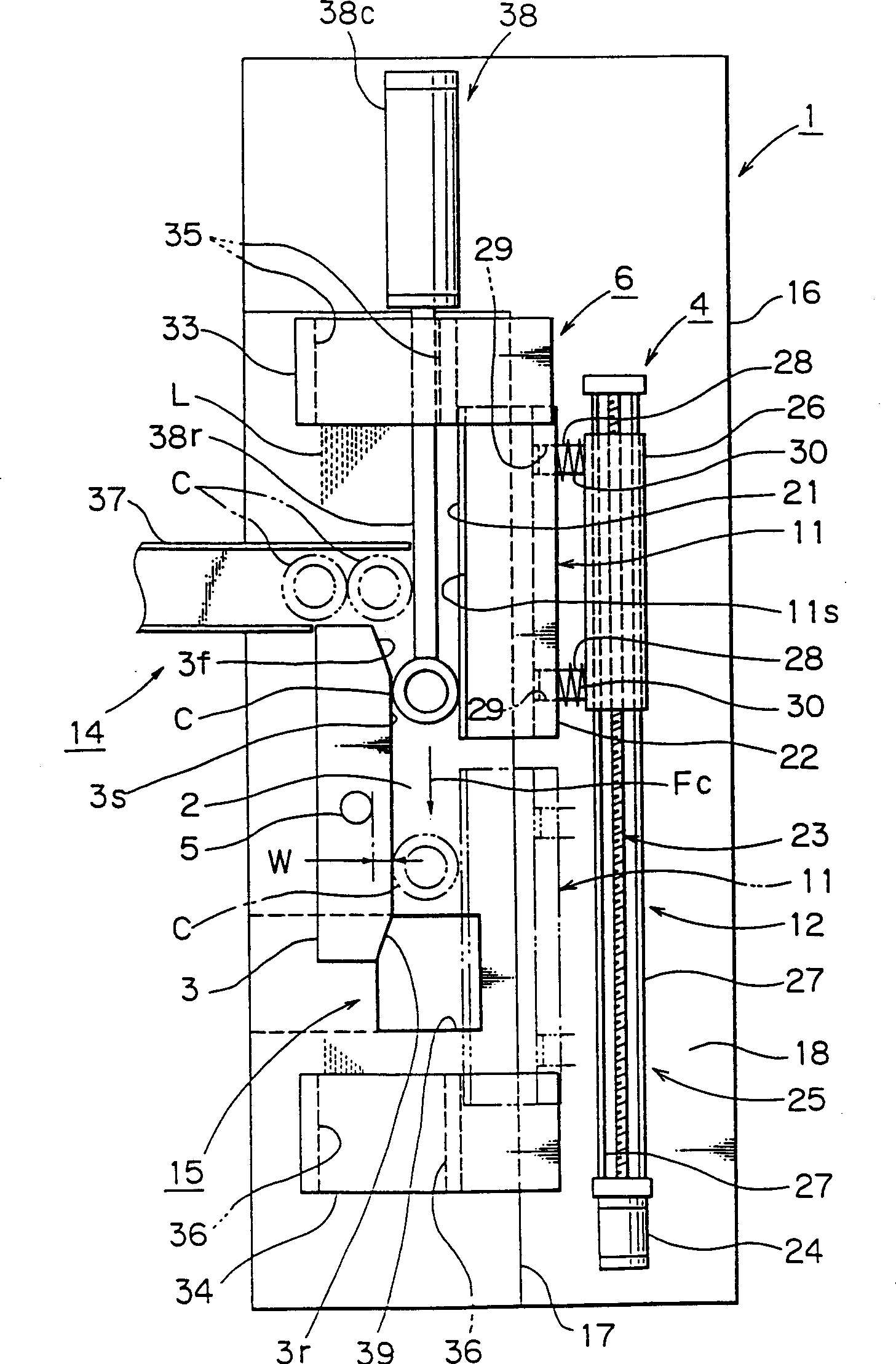

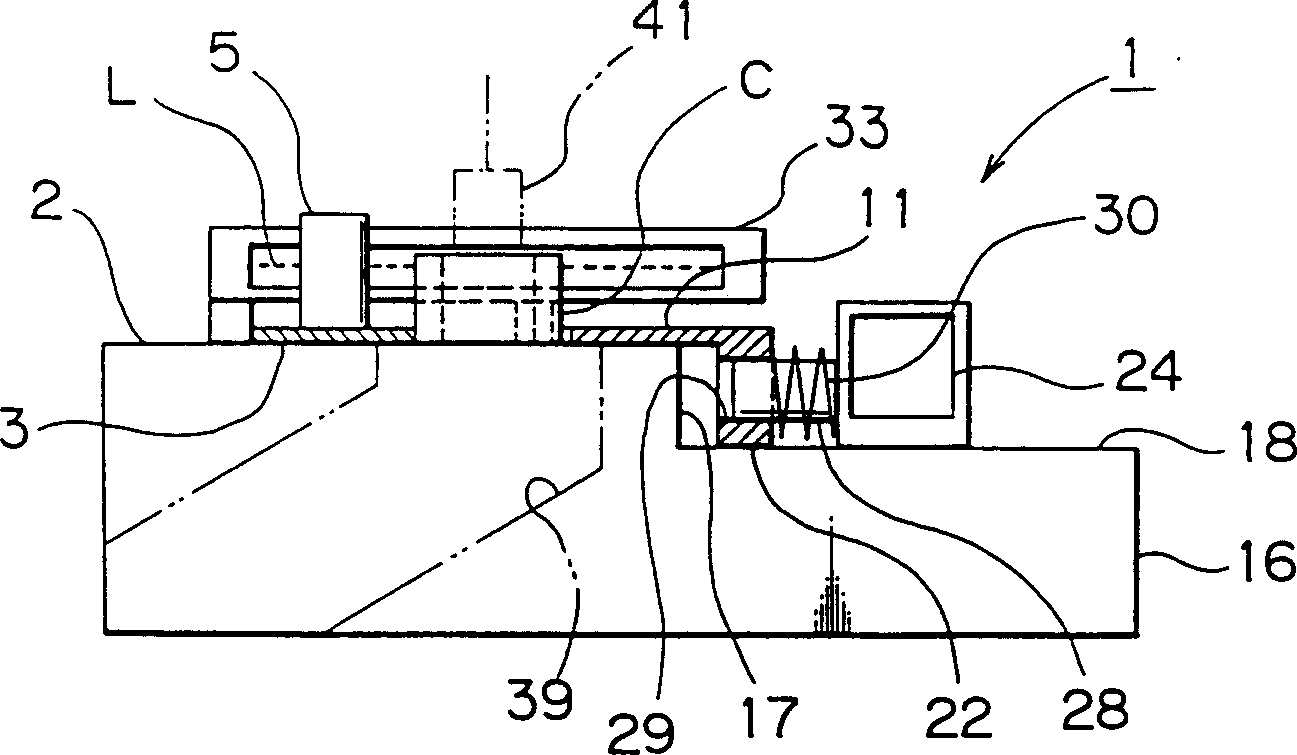

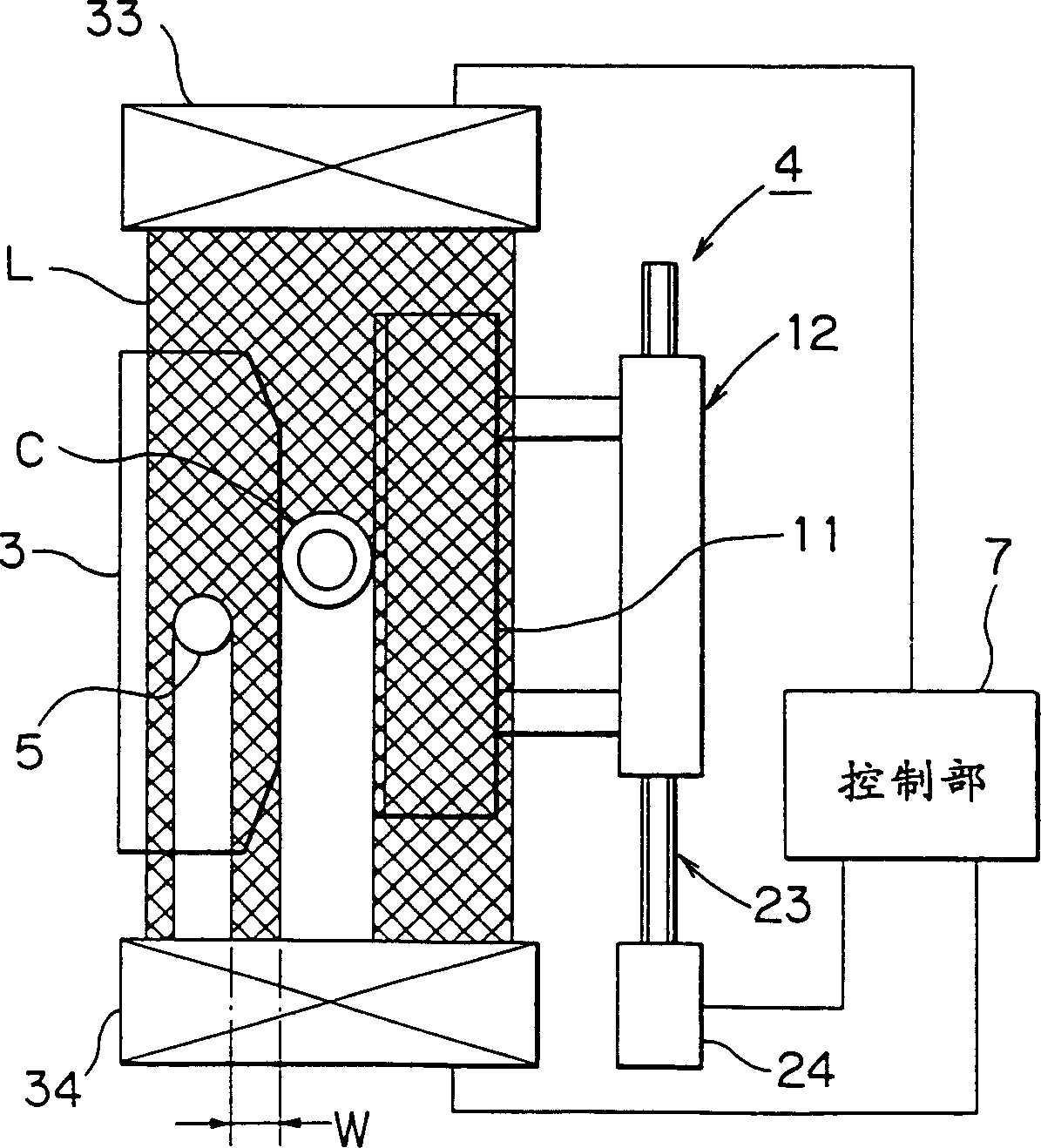

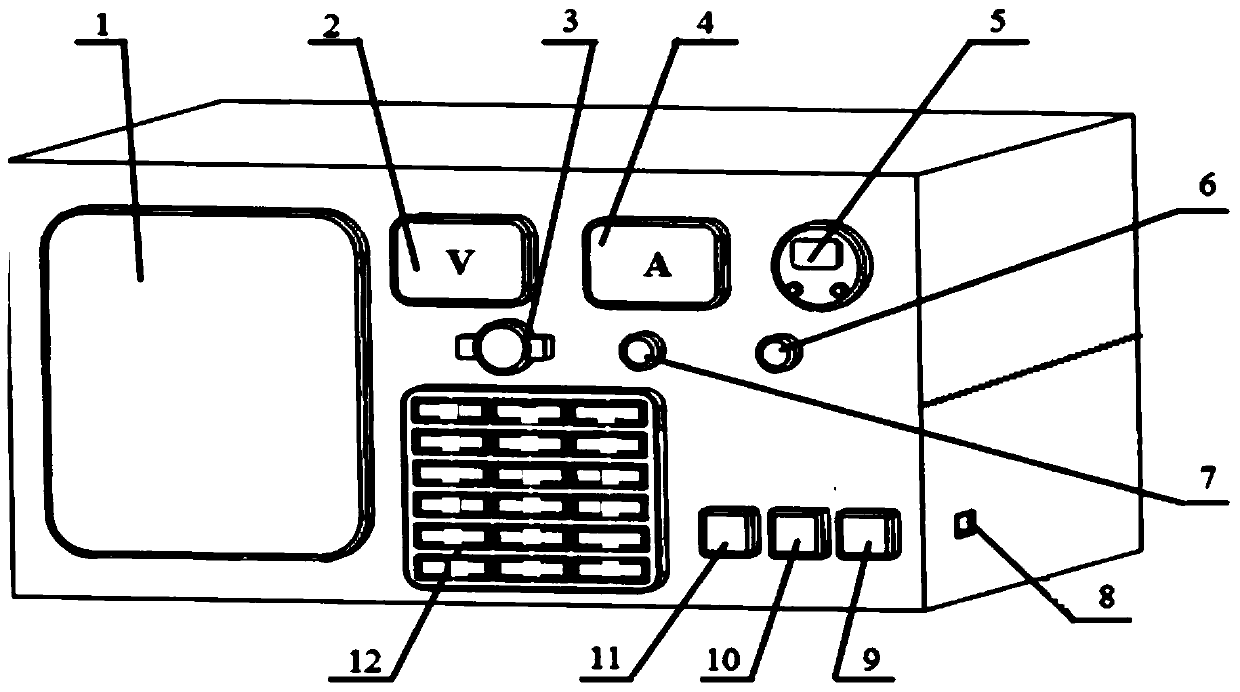

Deformation analyzer of barrel body

InactiveCN1382954AImprove stabilityImprove reliabilityRolling contact bearingsMaterial analysis by optical meansLaser lightMeasurement device

A cylindrical deformation measurement device, comprising: a fixed linear guide rail part 3 arranged on a flat surface 2, a cylindrical body transfer mechanism part 4, a reference column part 5, a laser scanning micrometer 6, and a control part 7 The cylindrical body transfer mechanism part 4 rotates the cylindrical body C in a state where the peripheral surface of one end side is in contact with the fixed linear guide rail part 3; the reference column part 5 is perpendicular to the rotational direction Fc of the cylindrical body C The laser scanning micrometer 6 scans the upper part of the cylinder C and the reference column part 5 simultaneously by the laser light L projected toward the rotation direction Fc, and measures the cylinder C. The interval W between C and the reference column portion 5; the control portion 7 measures the data to obtain the amount of deformation Ed. In this way, reproducible and highly accurate measurements can be performed, and at the same time, full automation can be easily performed, and more stable and reliable measurements can be performed.

Owner:MINEBEA CO LTD

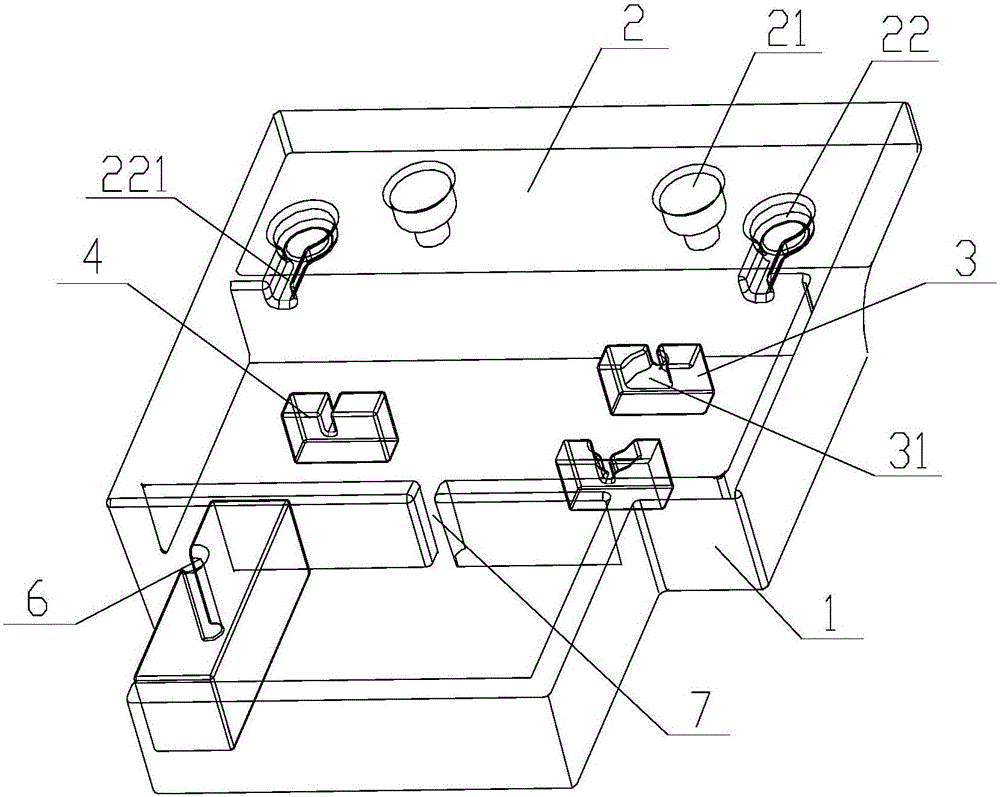

Universal earphone production tool and earphone production method

ActiveCN106358133AEasy to produceShorten production timeElectrical transducersDrive by wireIndustrial engineering

The invention provides a universal earphone production tool and an earphone production method. The universal tool comprises a bottom plate, an earphone shell storage area, a drive-by-wire clamping seat and a wire material storage plate which are sequentially arranged at the upper part of the bottom plate, wherein a jack corresponding to the plug of an earphone is formed in one side of the wire material storage plate, and a wiring groove is formed in one side of the drive-by-wire clamping seat; the plug is plugged into the jack, and the wire material of an earphone wire is arranged in the wire material storage plate; the drive-by wire of the earphone is arranged in the corresponding drive-by-wire clamping seat, the shell of the earphone is arranged in the earphone shell storage area; and a speaker body, a shell and an earphone wire of the earphone are assembled and connected, and the earphone wire connected with the speaker body is limited in the wiring groove. By utilizing the method, abrasion of the earphone appearance in the earphone producing process can be reduced, the earphone production time can be saved, and the production efficiency can be improved.

Owner:GOERTEK INC

Method for quickly preparing nano thermal insulation material by supercritical drying

PendingCN111778649AEliminate curing and molding stepsAvoid contactFibre treatmentSolvent treatment with solvent recoverySupercritical dryingFiber

The invention discloses a method for quickly preparing a nano thermal insulation material by supercritical drying. The method combines liquid preparation, dipping, gelation and drying. After fiber felt rolls are directly immersed in a drying kettle for molding and solidification, the fiber felt rolls are directly heated to dry with supercritical methanol or ethanol, so as to achieve complete sealing to prepare the nano thermal insulation material. The method omits the curing and molding step of fiber felt, injects gel solution into the drying kettle, uses the adsorption performance of the fiber felt to remove the excess gel, and directly performs supercritical drying after gelation. The method has simple process, is easy to realize complete automation, saves much equipment investment, at the same time avoids a large amount of organic solvent volatilization and personnel contact with volatiles, and the waste heat recovery in the production process can save energy to the greatest extent.

Owner:中化学华陆新材料有限公司

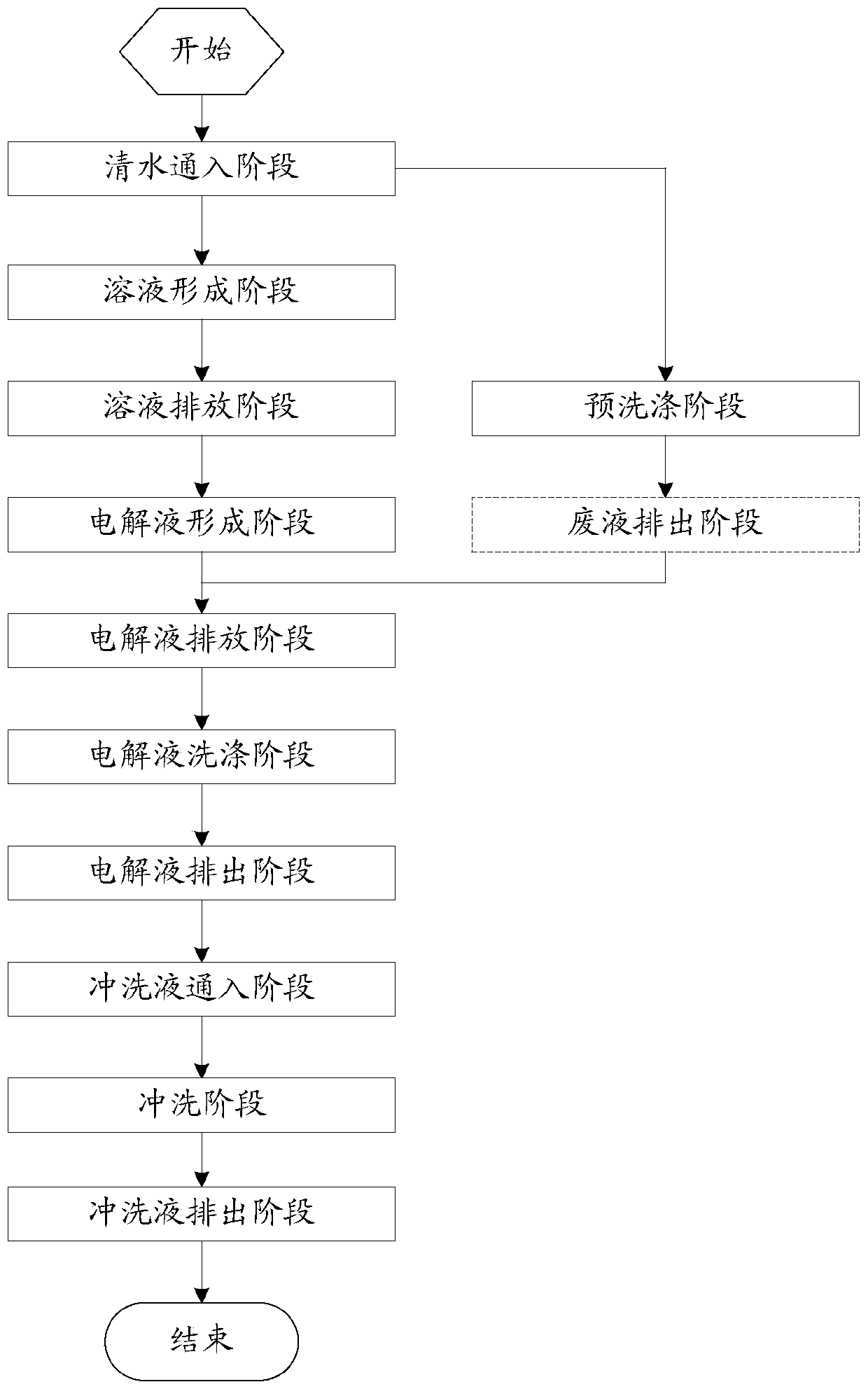

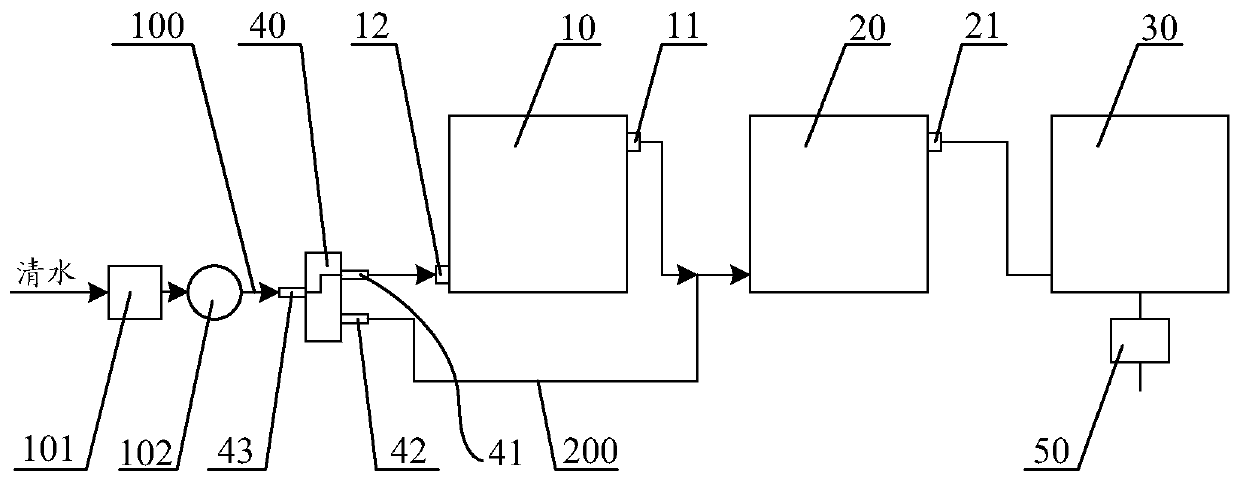

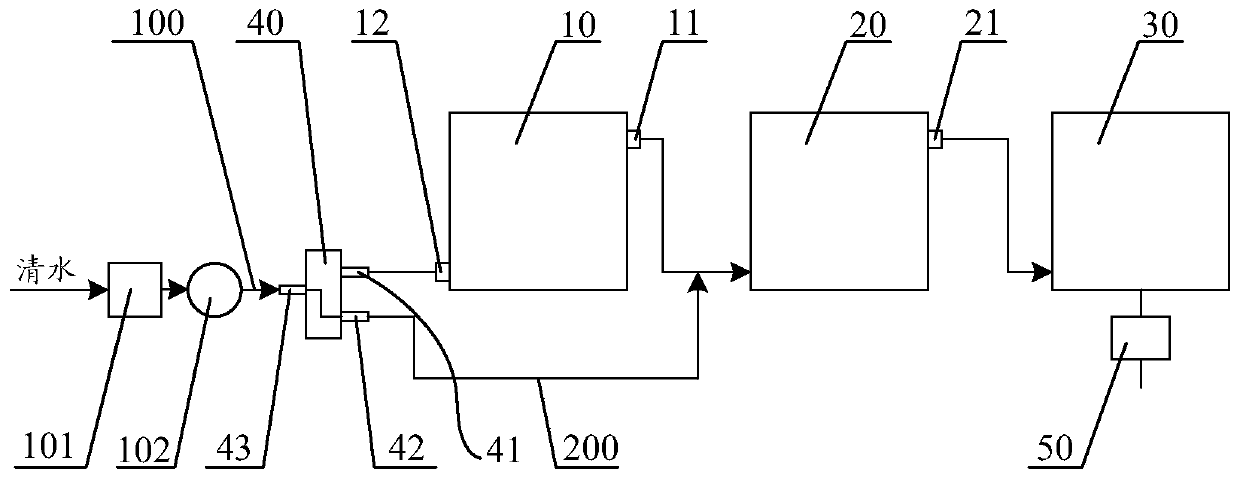

Washing method of washing system

ActiveCN109730611AImprove predictabilityImprove experienceCellsTableware washing/rinsing machine detailsElectrolytic agentAutomation

The invention discloses a washing method of a washing system. The washing method comprises an electrolyte washing process which comprises the following steps: a solution formation stage: introducing clean water into a dissolving cavity, so as to form an electrolyte solution; a solution discharging stage: discharging the formed electrolyte into an electrolysis cavity; an electrolyte formation stage: electrolyzing the electrolyte solution, so as to generate electrolyte with a set ion concentration; a electrolyte discharging stage: discharging the electrolyte with the set ion concentration into awashing cavity; and an electrolyte washing stage: washing objects in the washing cavity by virtue of the electrolyte with the set ion concentration. According to the washing method, the complete automation of the washing can be easily realized, so that the washing efficiency is improved, and the user experience is improved; and besides, the ion concentration of electrolyte can be in a predictablestability range in each washing process, so that the stability of the washing effect is guaranteed, and the predictability of the washing effect is improved.

Owner:JOYOUNG CO LTD

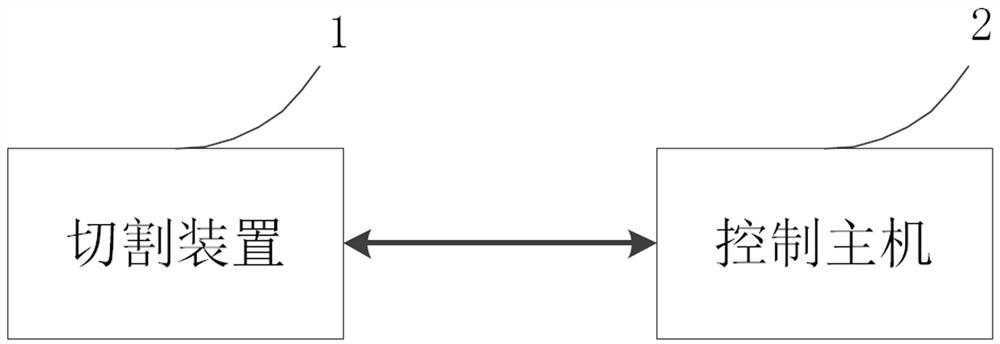

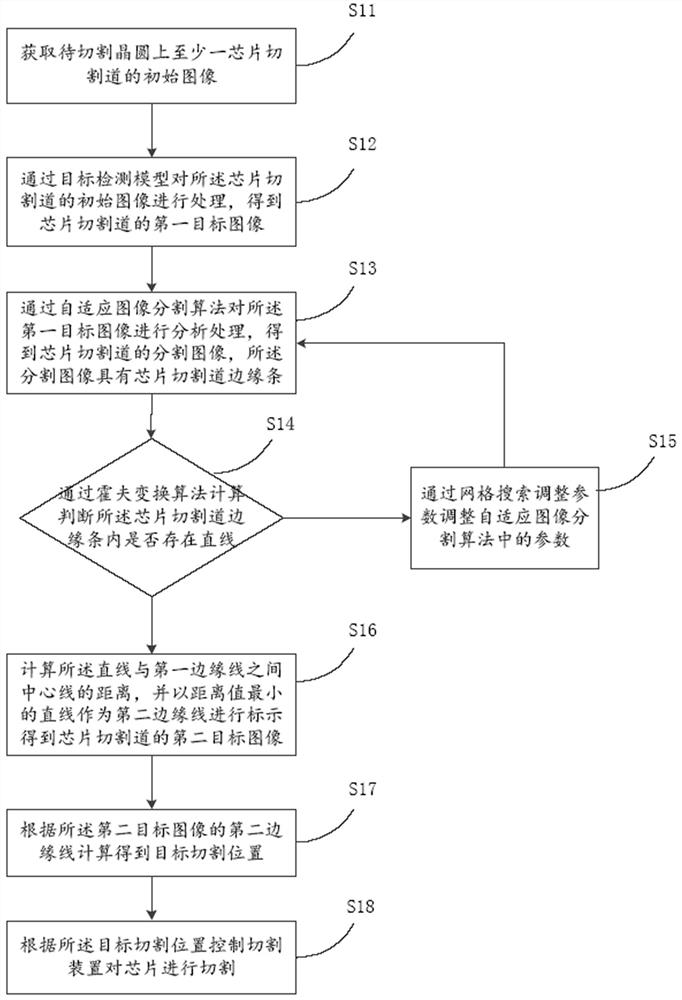

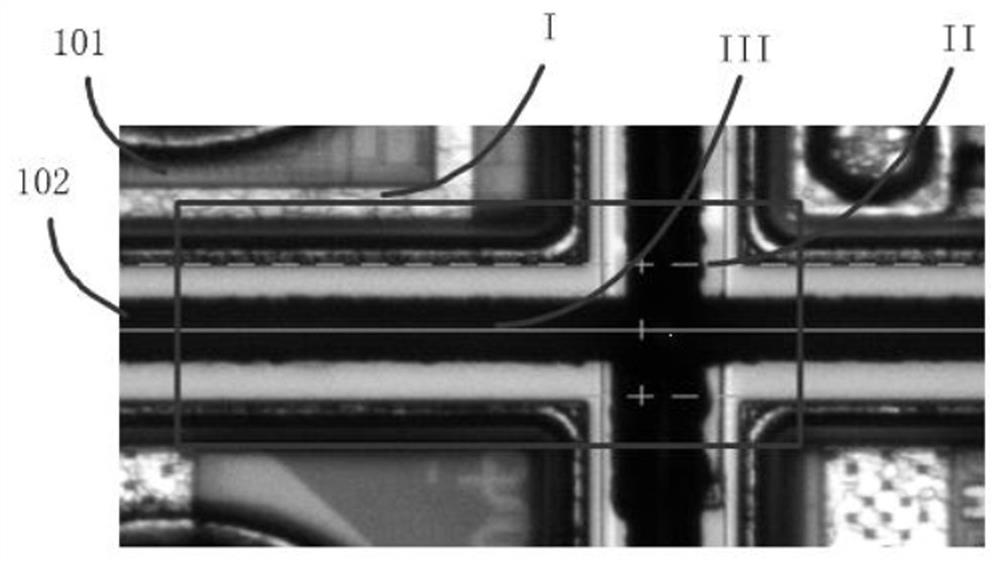

Chip cutting control method and system, equipment and computer readable storage medium

PendingCN113240693AImprove efficiency and chip cutting accuracyShorten the timeImage enhancementImage analysisEmbedded systemComputer hardware

The invention discloses a chip cutting control method and system, equipment and a computer readable storage medium. The method comprises the following steps: acquiring an initial image of at least one chip cutting channel on a wafer to be cut; processing the initial image of the chip cutting channel through a target detection model, obtaining a first target image of the chip cutting channel, wherein the first target image is provided with a first edge line of the chip cutting channel; carrying out edge line positioning analysis on the first target image, and obtaining a second target image of the chip cutting channel, wherein the second target image is provided with a second edge line of the chip cutting channel; calculating a target cutting position according to a second edge line of the second target image; and controlling a cutting device to cut the chip according to the target cutting position. According to the invention, the chip production efficiency is improved, the correction and alignment precision of the cutting knife is improved, the rejection rate of products is reduced, the production cost is reduced, and the full automation of the chip cutting process is realized.

Owner:珠海埃克斯智能科技有限公司

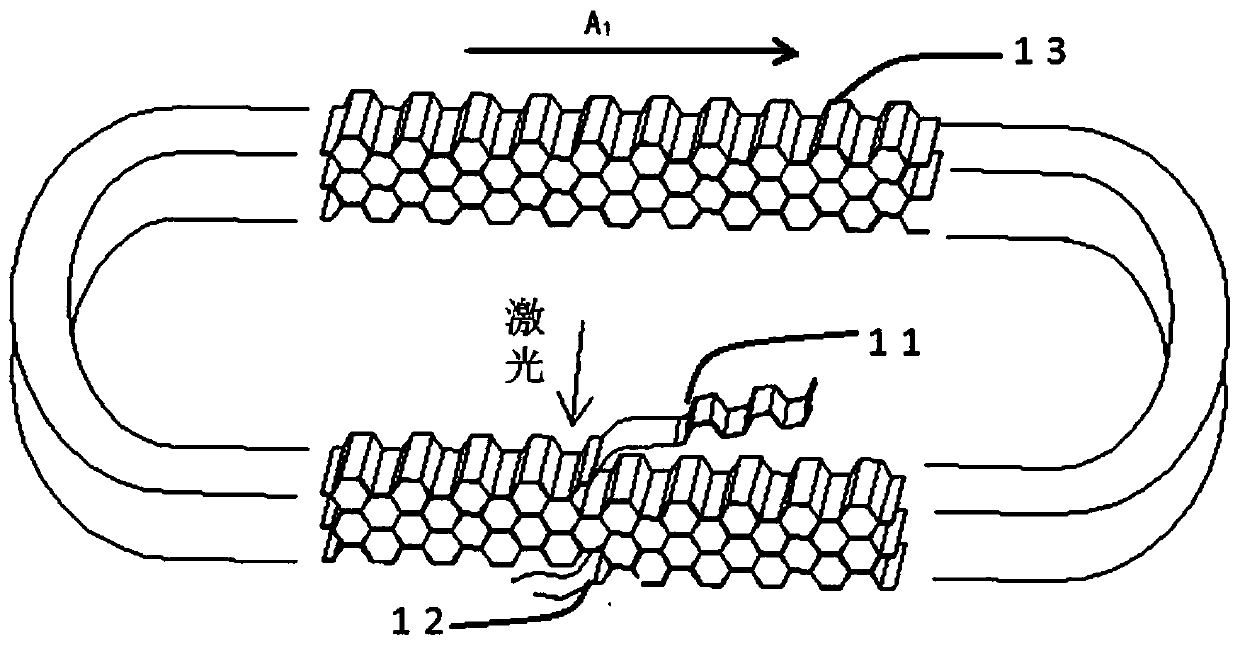

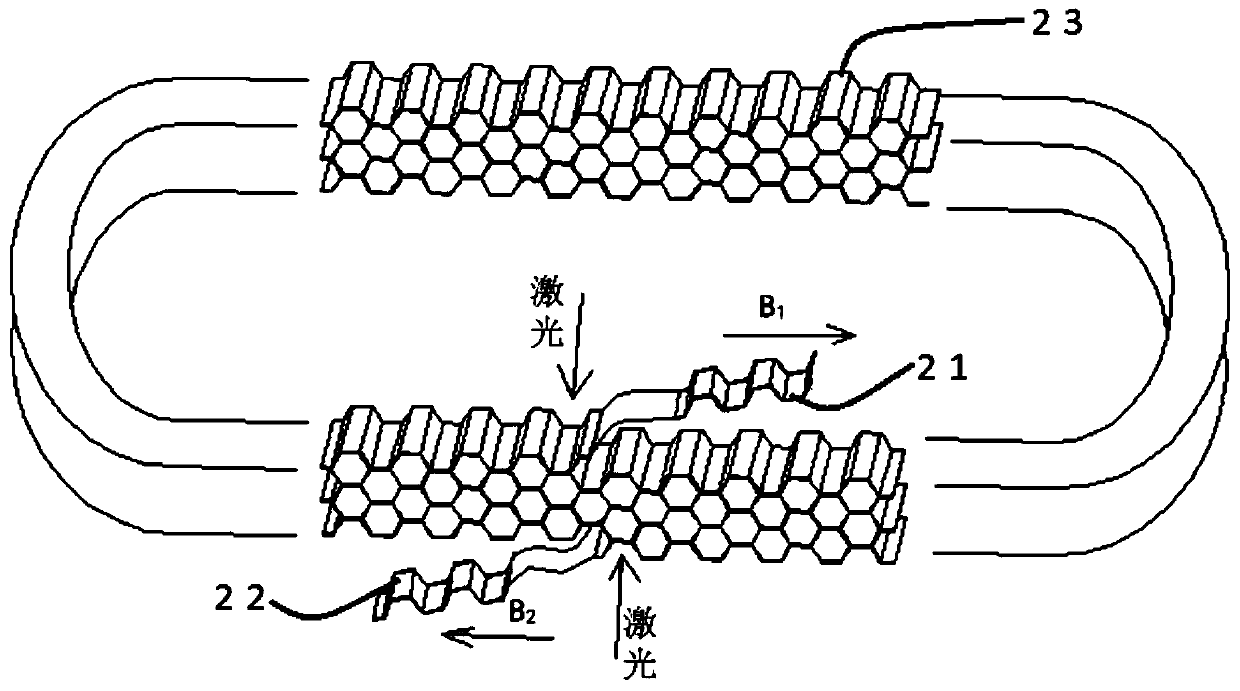

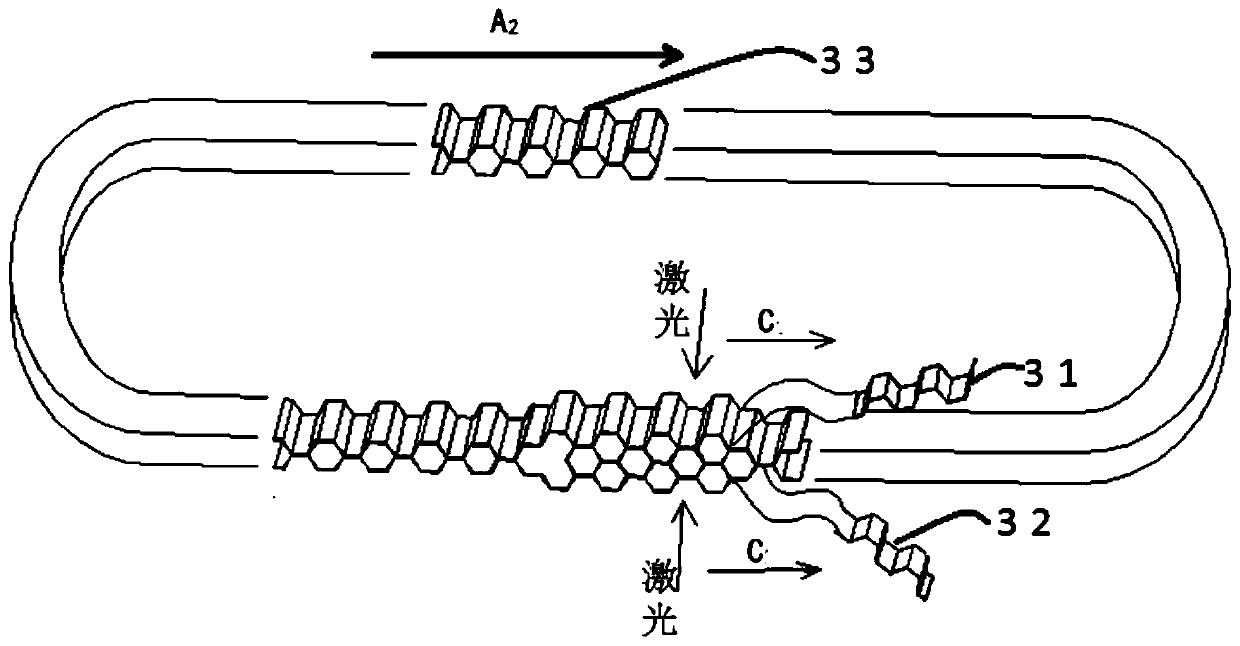

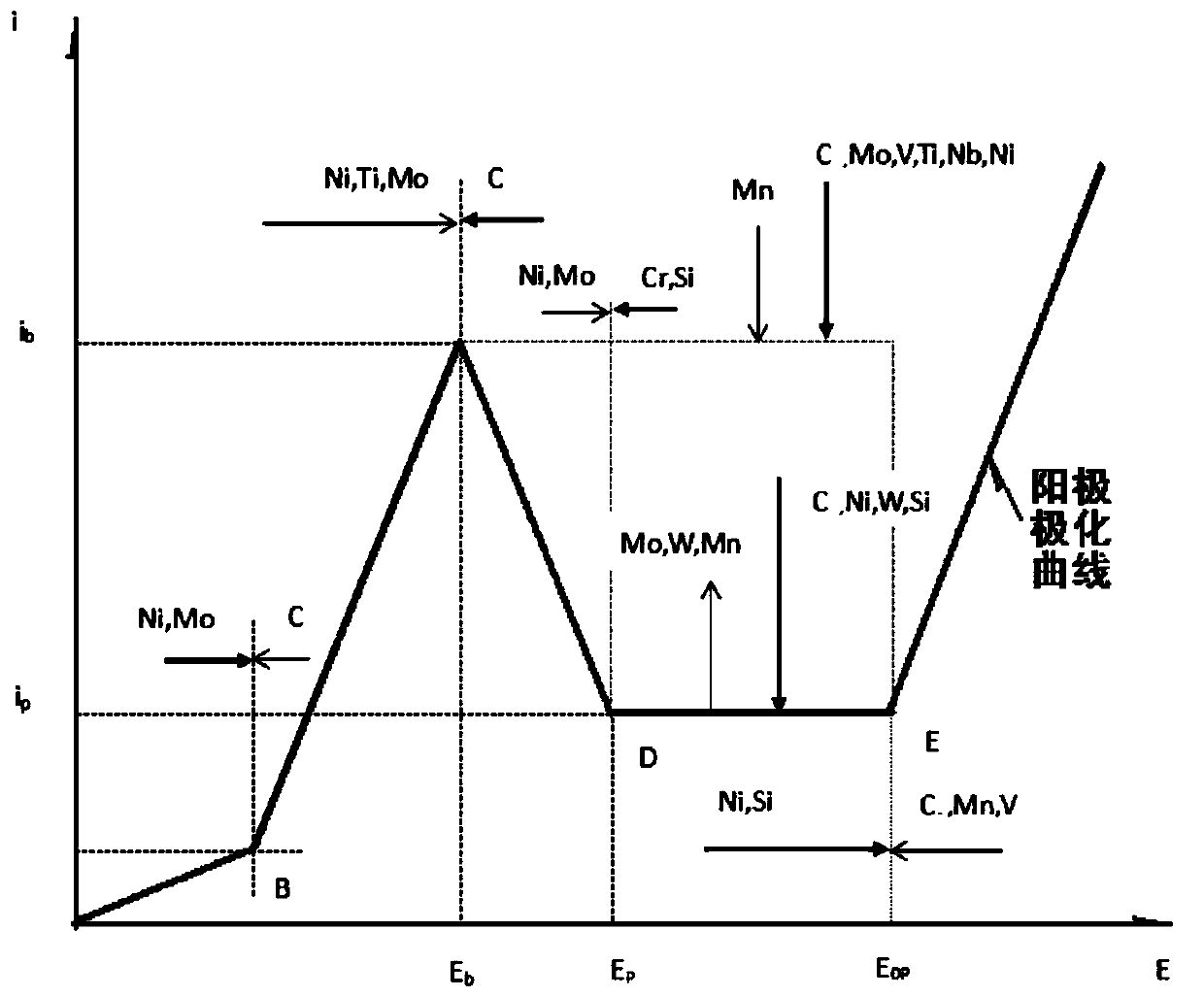

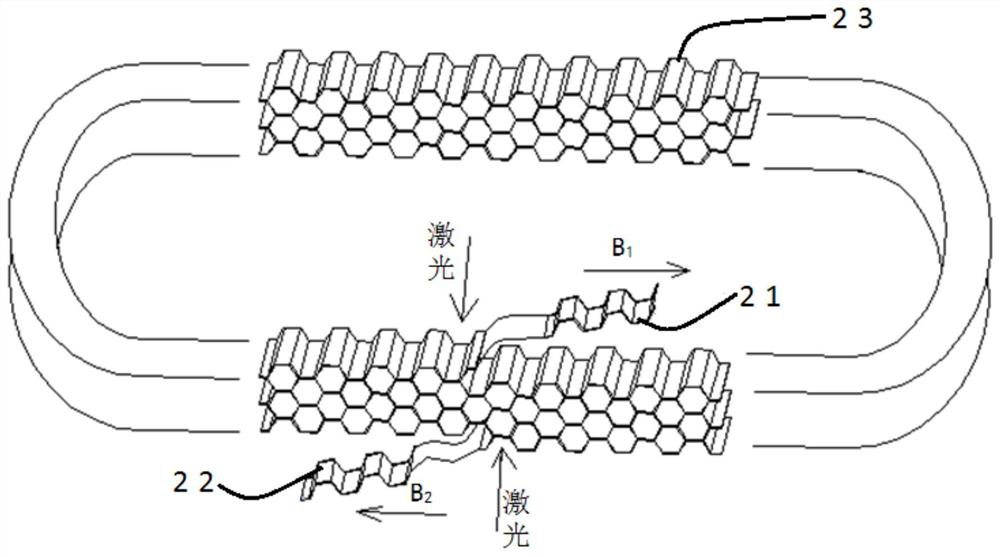

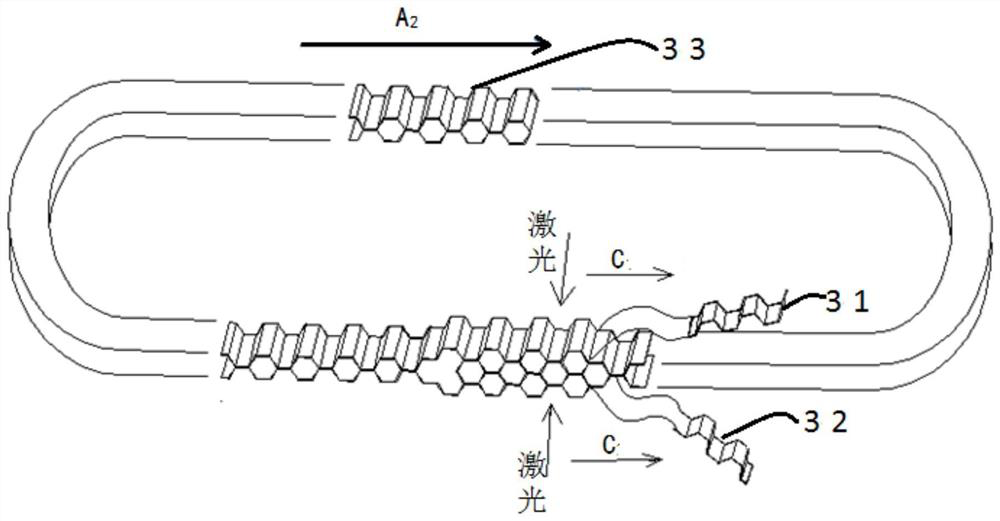

Manufacturing method for honeycomb structure

ActiveCN109848558AAvoid deformation effectsContinuityWelding/soldering/cutting articlesMetal working apparatusClosed loopHoneycomb structure

The invention provides a manufacturing method for a honeycomb structure. The manufacturing method comprises the steps that a corrugated ribbon is provided, wherein the corrugated ribbon is constitutedthrough alternative connection of concave surface sections and convex surface sections, and any one of the concave surface sections and any one of the convex surface sections in the corrugated ribbonare used to form a honeycomb core grid after closed loop connection; the corrugated ribbon is annularly coiled axially with an axis as the center, so the convex surface sections and the concave surface sections can overlay to constitute a plurality of honeycomb core grids, and then the sealed loop is constituted by the honeycomb core grids; and overlaid positions between the sections of the corrugated ribbon are fixedly connected, so the honeycomb structure constituted through successive connection of the honeycomb core grids is obtained. The manufacturing method provided by the invention isdifferent from traditional honeycomb processing in that overall cutting is carried out after processing of the honeycomb structure, so a process for single sheet cutting is omitted during production,production efficiency is greatly increased and manpower cost is reduced; the cutting process and influences of cutting on belt deformation are avoided, so product quality is greatly improved; and themanufactured honeycomb cores are continuous and circulative as a whole.

Owner:BEIJING ANDER TECH

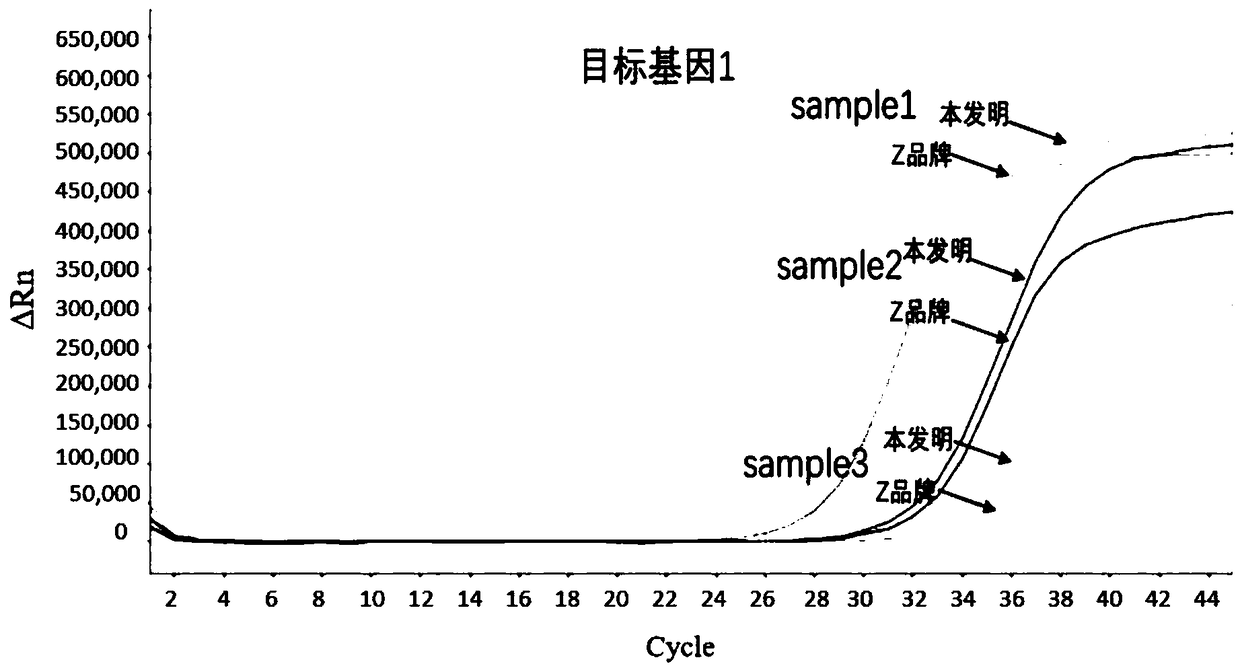

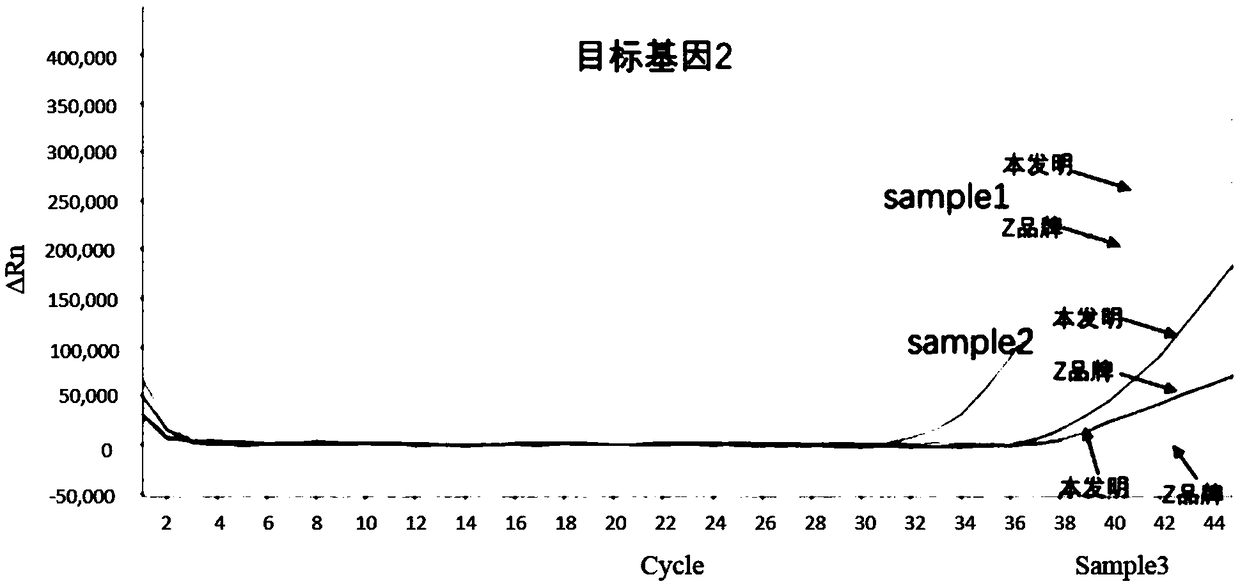

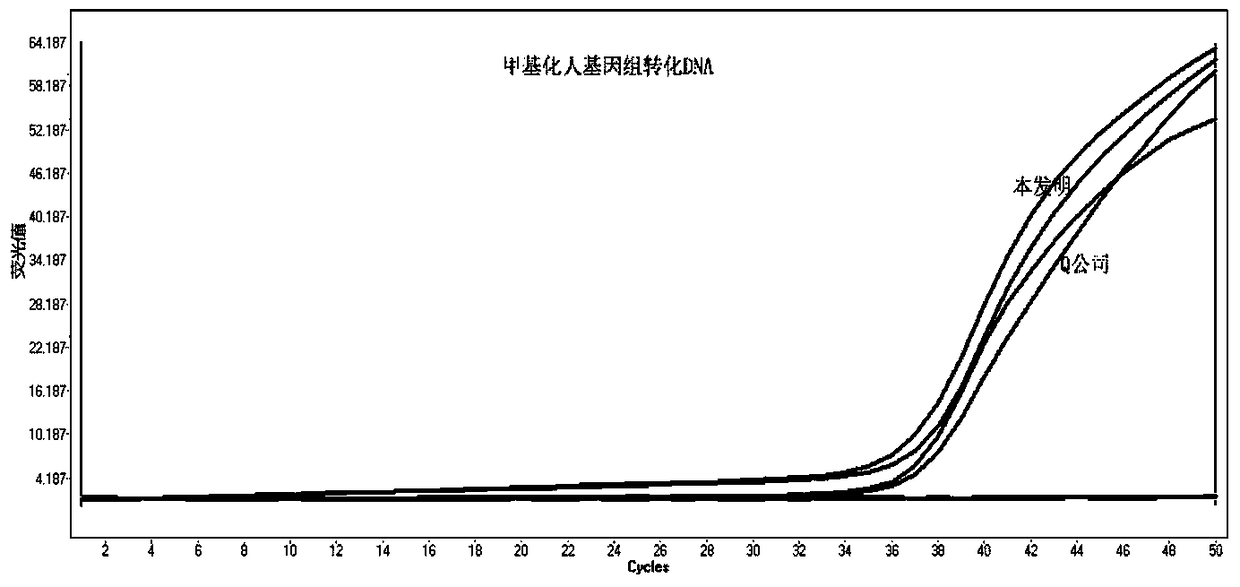

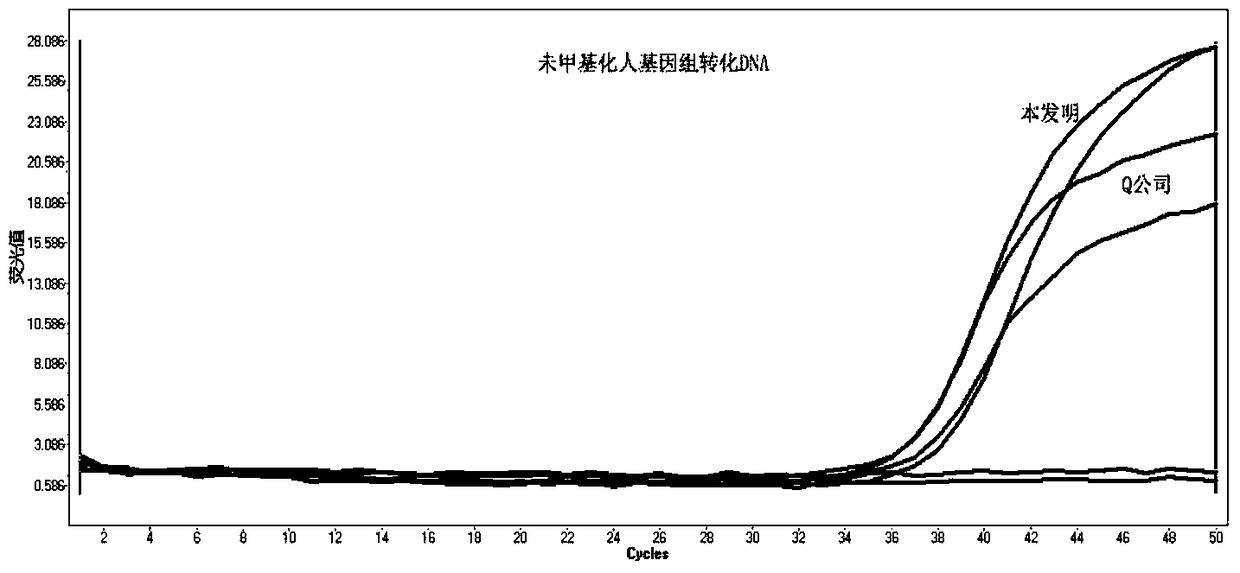

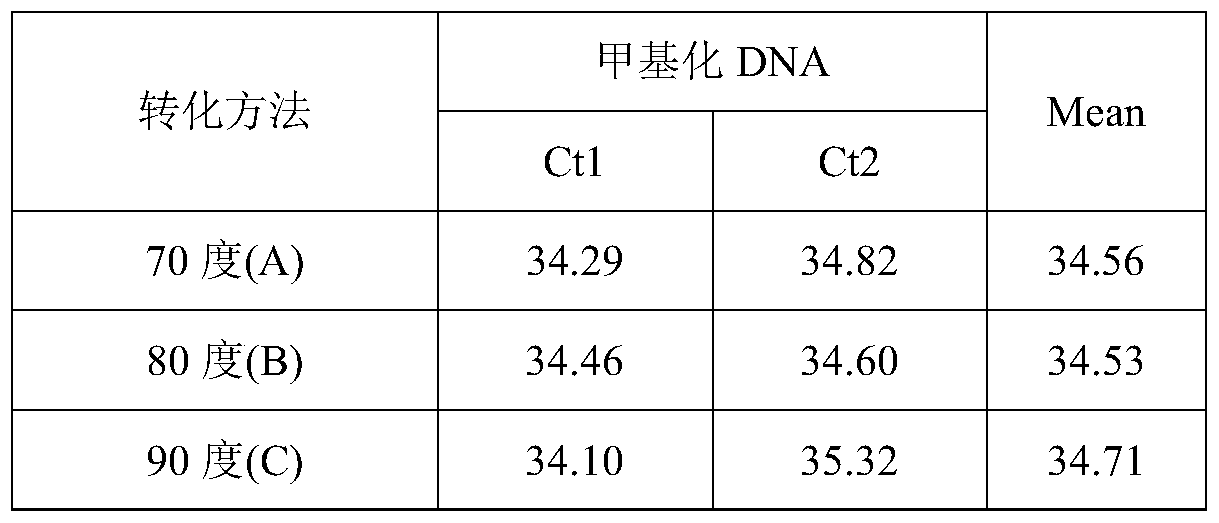

Nucleic acid purification method for DNA methylation analysis of human-derived stool

ActiveCN109439726ASimple and fast operationImprove conversion rateMicrobiological testing/measurementDNA methylationPurification methods

The invention provides a nucleic acid purification method for DNA methylation analysis of human-derived stool. The method comprises steps as follows: an initial nucleic acid sample is subjected to denaturation treatment; a denaturation treatment product is subjected to conversion treatment for 40-50 min at the temperature of 75-80 DEG C, un-methylated cytosine in the denaturation treatment productis converted into uracil in the conversion treatment process, and methylated cytosine is still cytosine; a conversion treatment product is purified, and a nucleic acid sample for DNA methylation analysis is obtained; the conversion treatment is performed in the presence of sodium hydrogen sulfite, sodium sulfite and a protective agent. The method can be effectively applied to methylation analysisof the low- content human-derived DNA sample such as DNA methylation analysis of human-derived stool, converted DNA with high conversion rate and high quality is obtained, and fully-automatic and standard operation of methylation study is facilitated.

Owner:SHANGHAI REALBIO TECH CO LTD

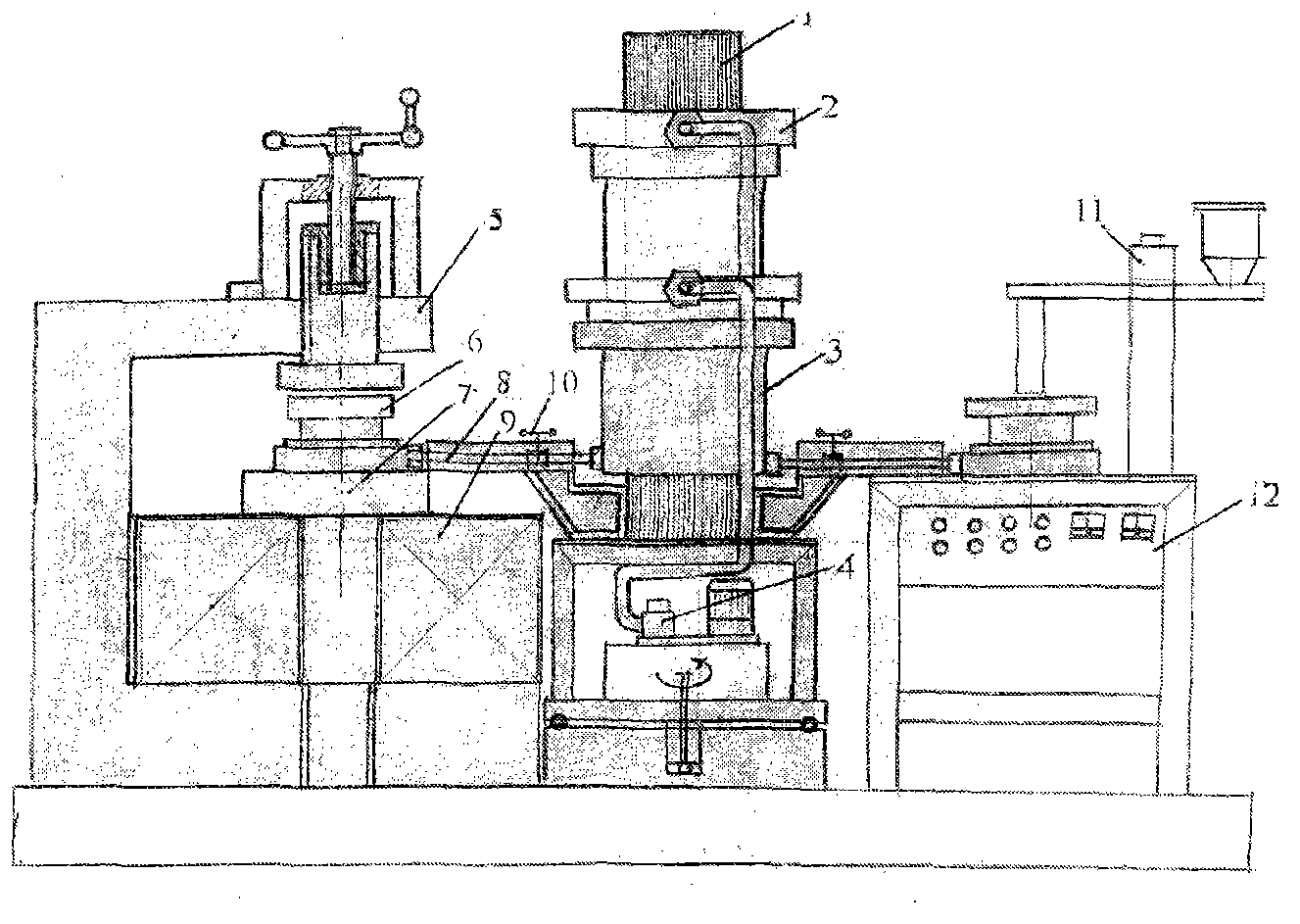

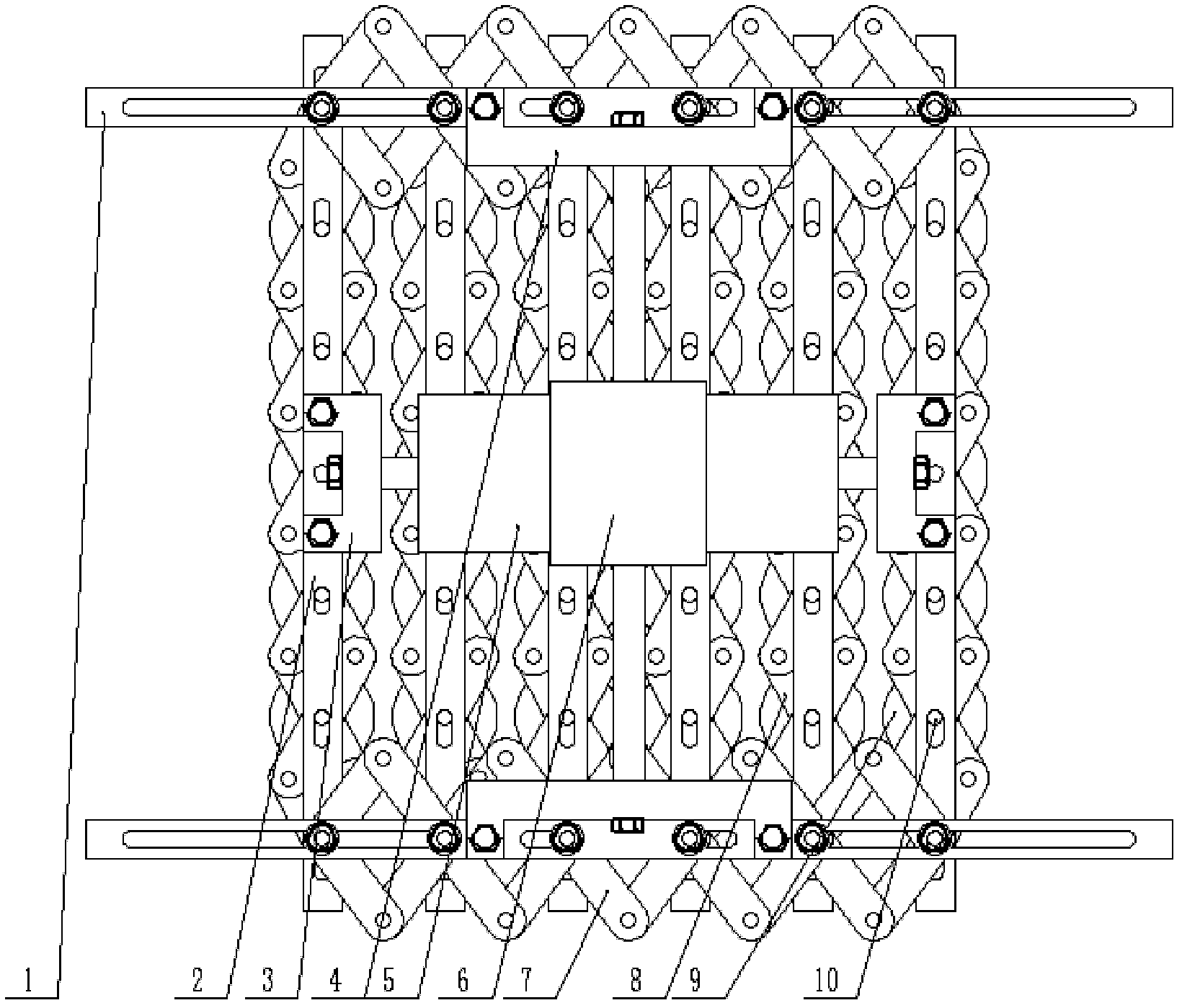

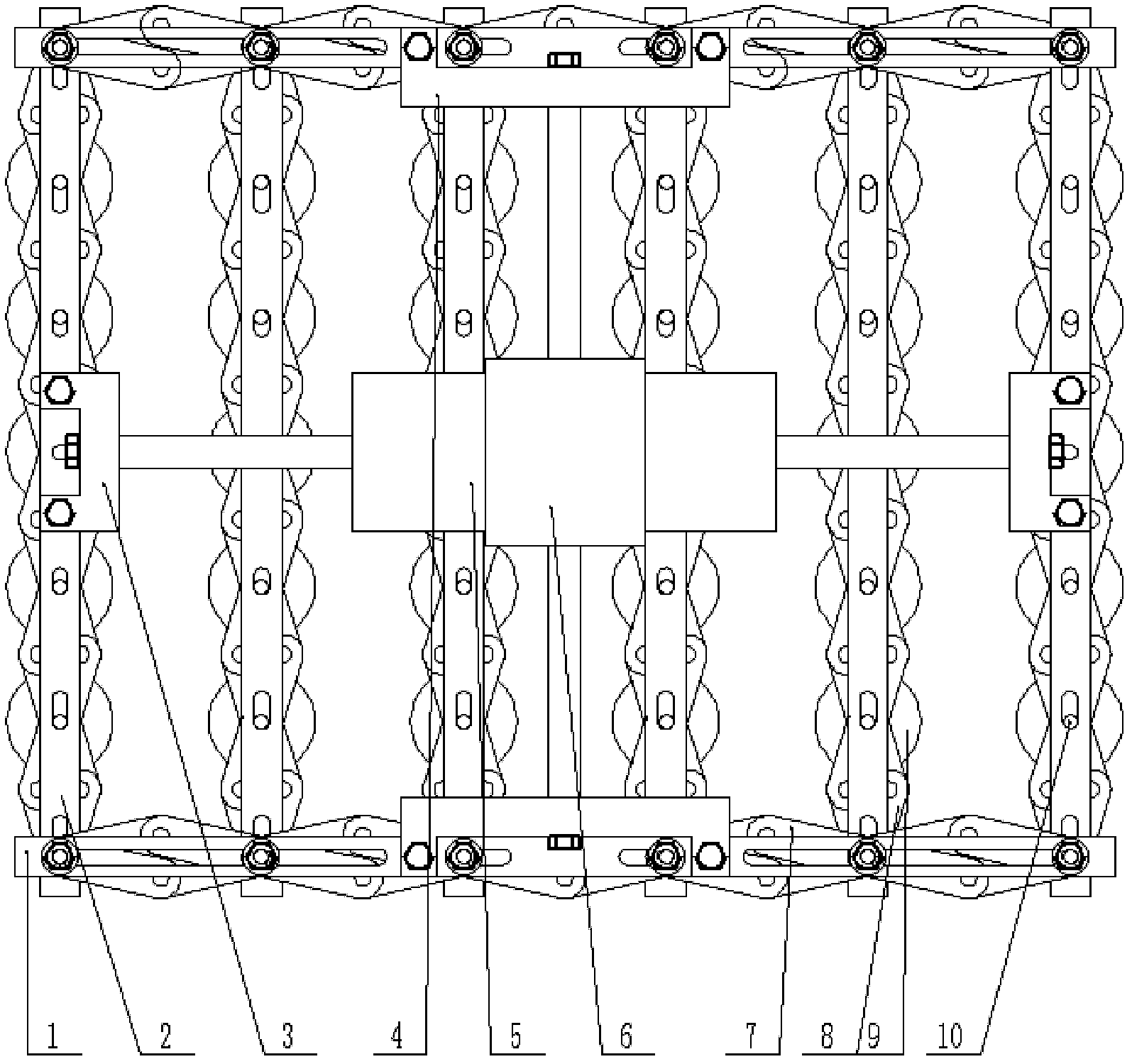

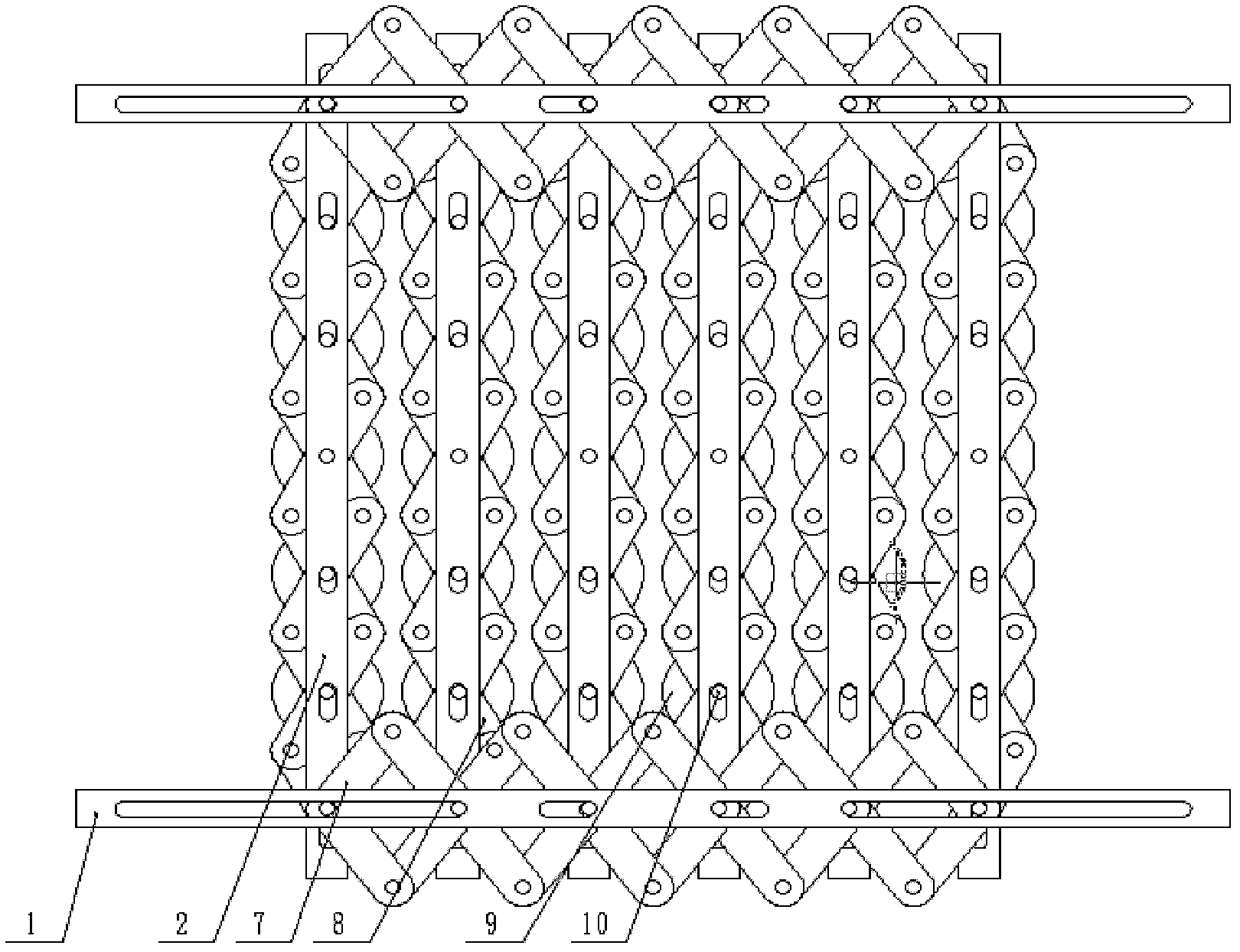

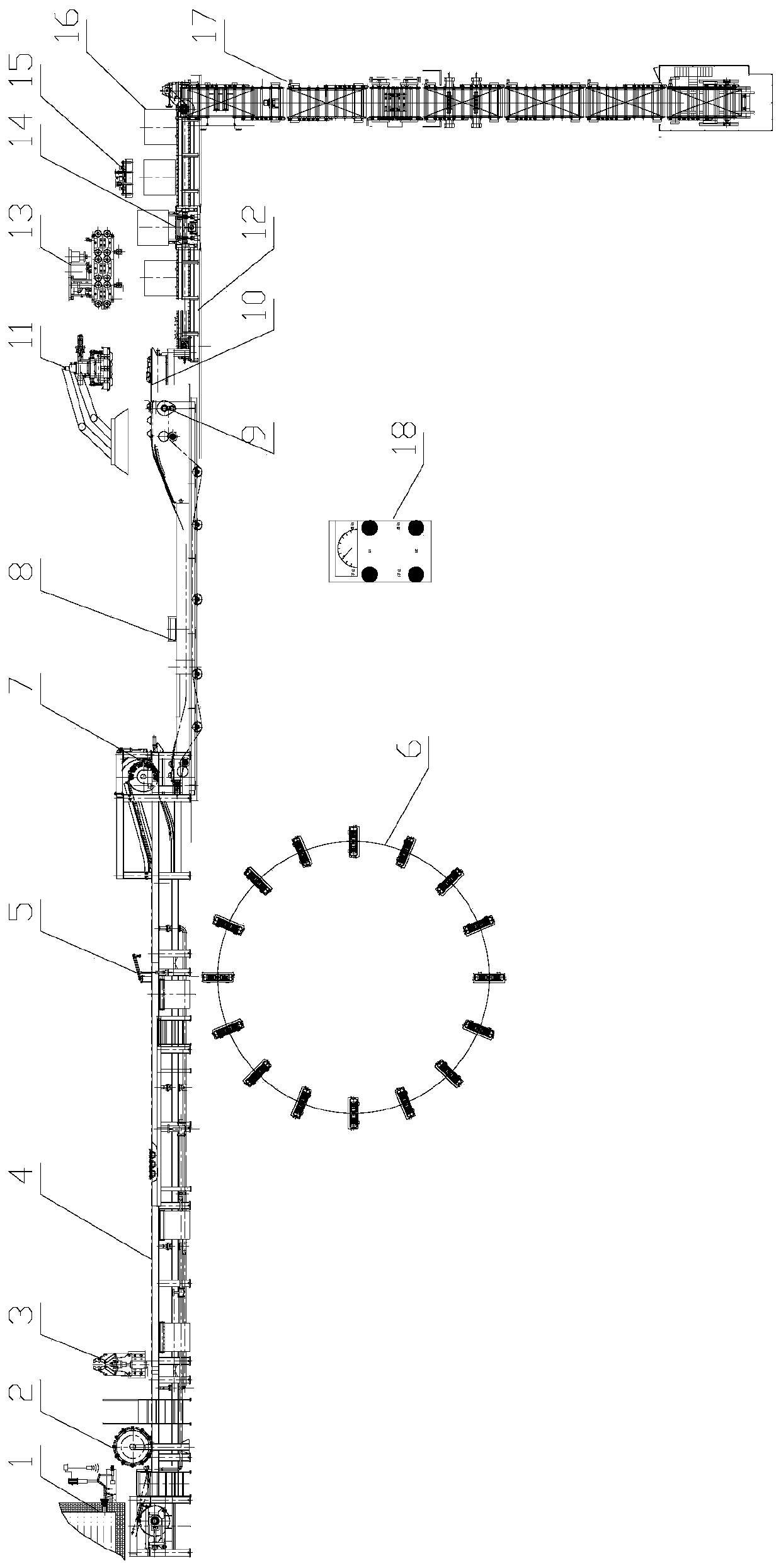

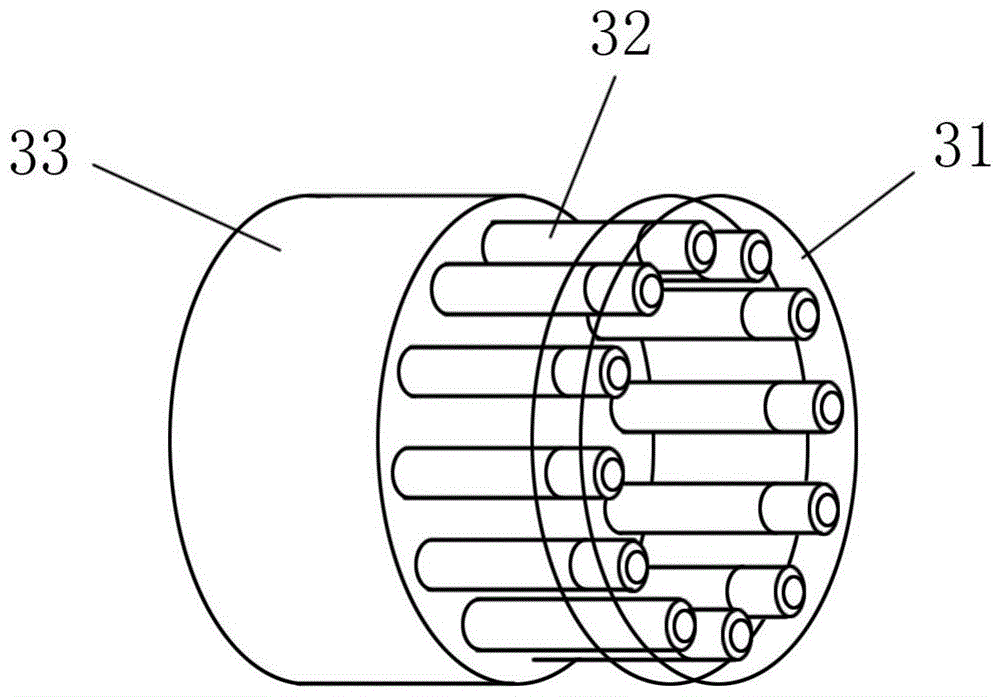

Full-automatic continuous type secondary heating device for semisolid metal blanks

The invention relates to a full-automatic continuous type secondary heating device for semisolid metal blanks and belongs to the technical field of semisolid metal processing. The full-automatic continuous type secondary heating device comprises an induction heating power supply, an induction heating mechanism, a material carrying and conveying mechanism, a blank rotating mechanism and an automatic feeding mechanism. The induction heating mechanism comprises seven induction heating coils and a drive device, the induction heating coils are arranged on the drive device, the seven induction heating coils and one vacancy are evenly distributed at 45 degrees in the circumferential direction, and the coils are connected in series and are connected with the induction heating power supply. The blanks are placed on the material carrying and conveying mechanism through the automatic feeding mechanism and sequentially heated by the seven induction heating coils, and the blank rotating mechanism is connected to the material carrying and conveying mechanism, so the blanks can be in a continuous rotation state in the heating process. The full-automatic continuous type secondary heating device can meet requirements for quick heating, even temperature and full-automatic heating in the aluminum alloy semisolid thixotropic processing process and has the advantages of being safe to operate, stable in running and easy to control.

Owner:有研金属复材技术有限公司

Aluminum pig casting machine

PendingCN111515354AReduce exhaust pollutionShorten the timeMolten metal supplying equipmentsIngot casting plantsElectrical controlProcess engineering

The invention aims at disclosing an aluminum pig casting machine. The aluminum pig casting machine comprises a molten aluminum flow automatic adjusting device, a molten aluminum distributing system, arobot slagging machine, a horizontal casting machine, an aluminum pig marking machine, a disc pig receiving conveyor, an electric chain pig receiving and holding device, a cooling conveyor, an aluminum pig overturning device, a whole row conveyor, a stacking robot, a finished product conveyor, an automatic bundler, an online weighing device, an aluminum pig stack laser marker, a storage plate chain and an electrical control system, wherein the parts are sequentially arranged. Compared with the prior art, the molten aluminum flow automatic adjusting device, the slagging robot, the automatic bundler, the online weighing device, the online marker and the delivery device are additionally arranged, full automation is achieved, the time is saved, the production efficiency is greatly improved, the cost is reduced, the aluminum pig casting machine is convenient and easy to carry out, and is easily achieved under existing conditions, and the purposes of the aluminum pig casting machine are achieved.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +2

A method for dna sulfite conversion and purification

ActiveCN105462960BShort conversion timeSimple equipmentMicrobiological testing/measurementDNA preparationMagnetic beadSulfite salt

The invention discloses a DNA sulfite conversion and purification method. The method does need early sodium hydroxide denaturating treatment conducted on nucleic acid, adopts varying-temperature conversion conditions different from a commercialized reagent on the market and can perform a conversion experiment under the constant temperature condition. A magnetic bead method is adopted to perform nucleic acid purification after nucleic acid methylation conversion, a high-salt low pH value is utilized to perform nucleic acid separation and purification, then a low-salt high pH value is utilized to perform elution, the step of performing desulfonating by adopting sodium hydroxide on the market at present is omitted in the purification process, and meanwhile high-conversion-rate, high-quality and high-purity DNA can be obtained only by adopting a one-step washing step. The DNA sulfite conversion and purification method has the advantages of being quick, simple and convenient to operate and improving the conversion efficiency, the extraction efficiency and the extraction purity.

Owner:杭州千基生物科技有限公司 +1

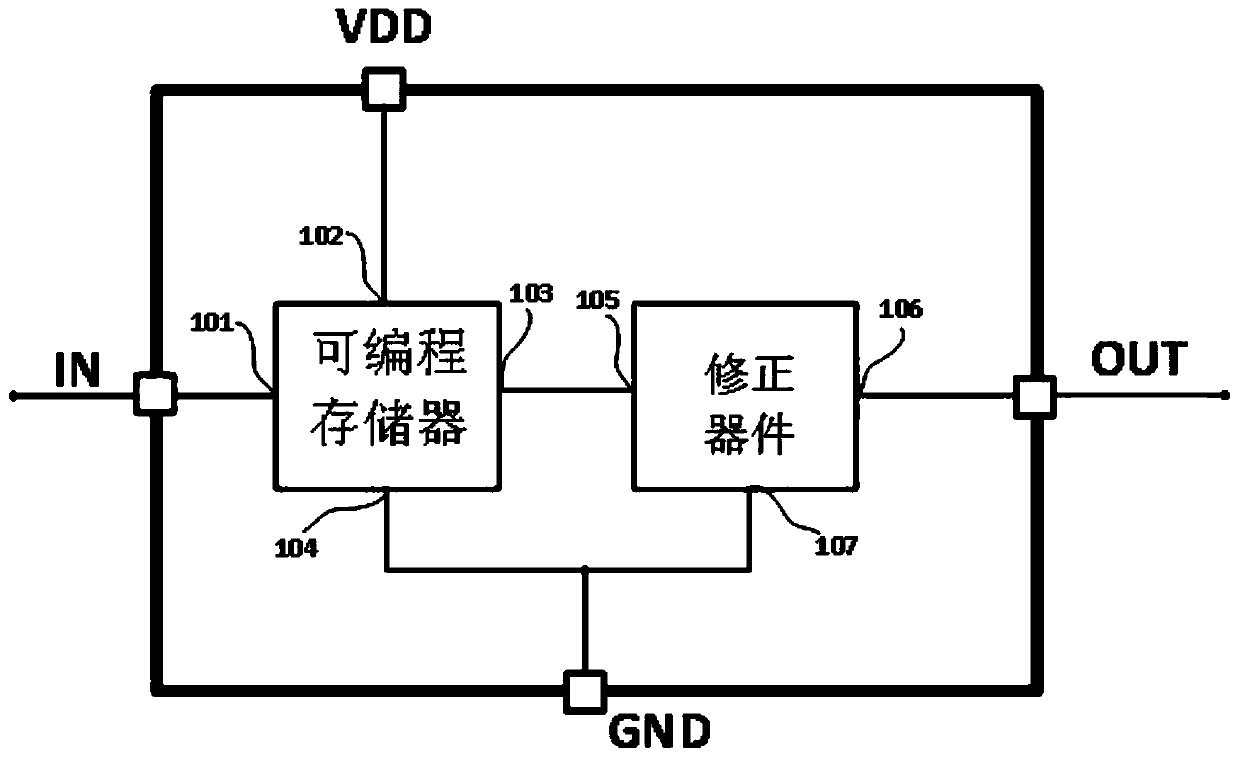

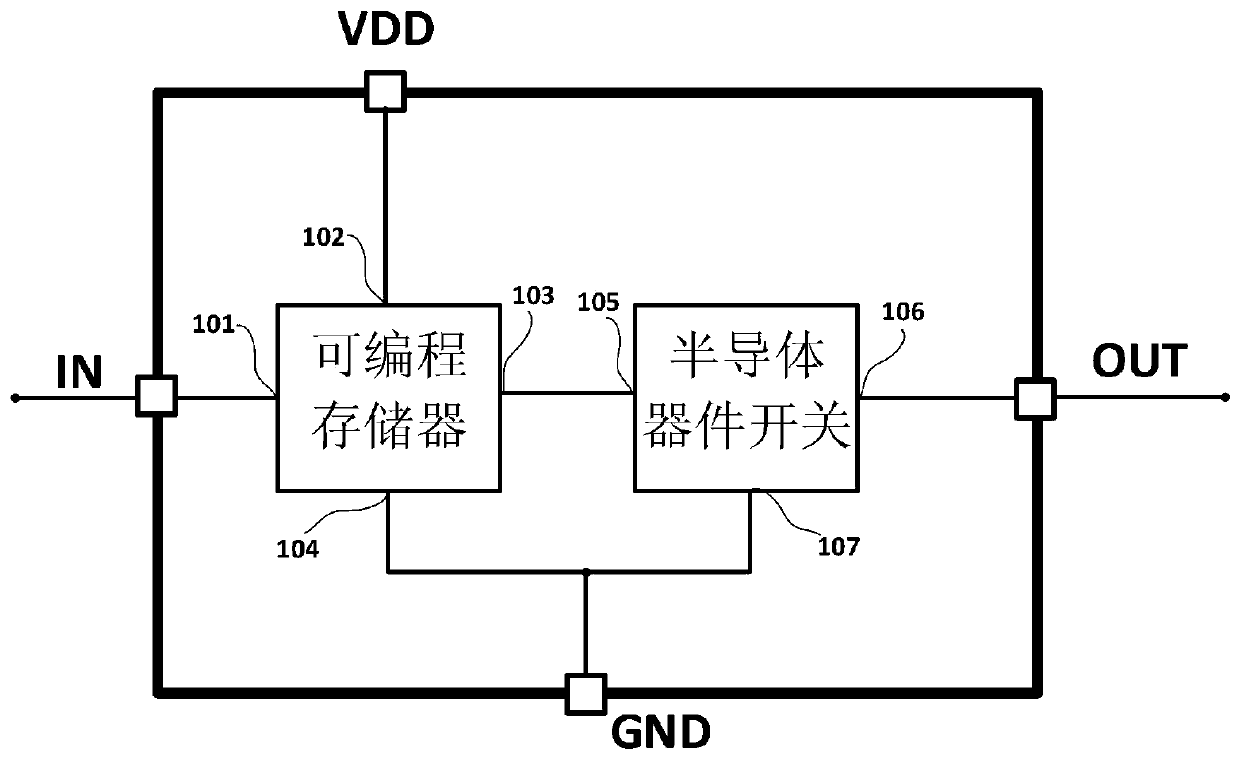

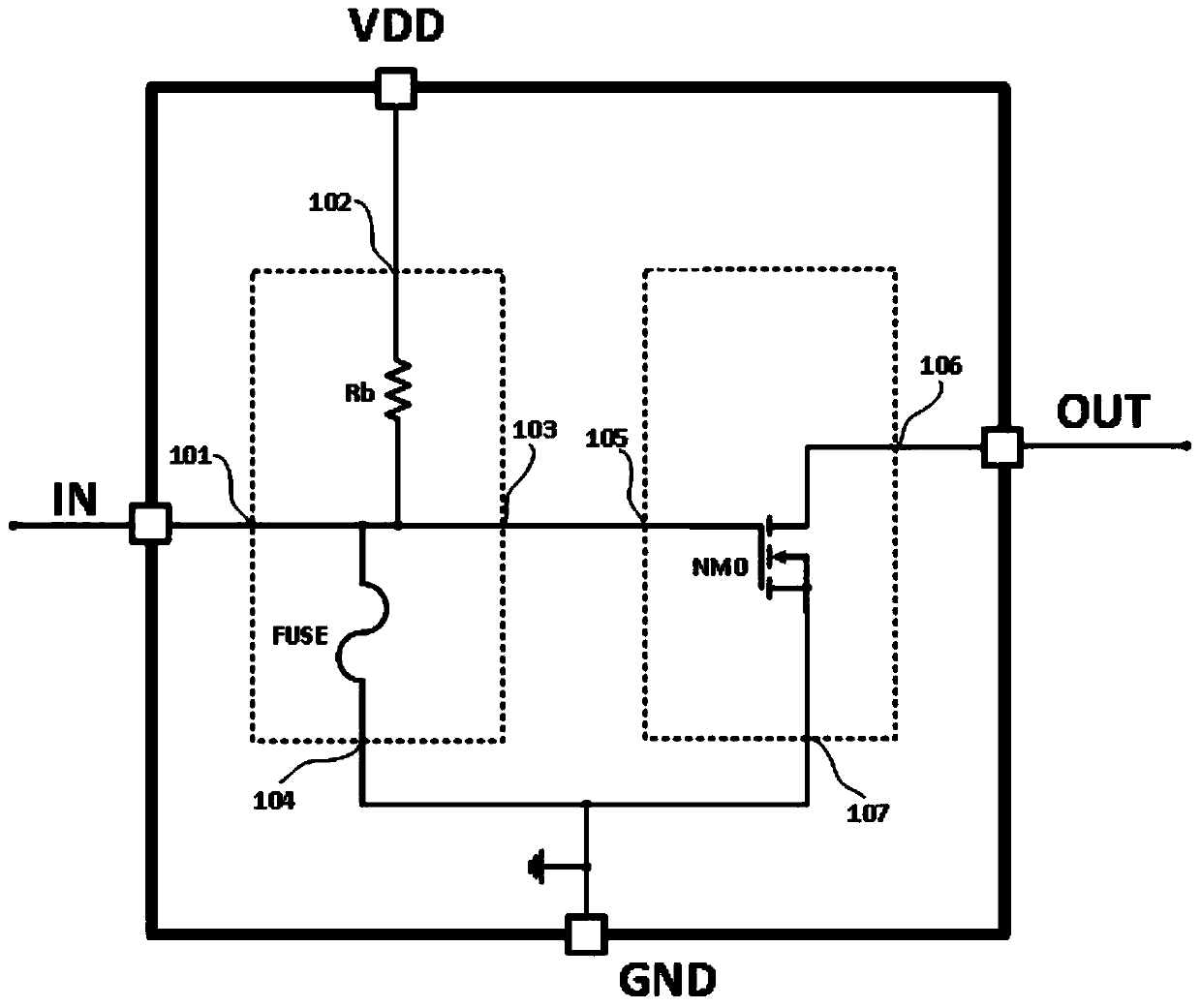

Electronic correction chip for circuit parameters of circuit board

InactiveCN110350768AEasy to fully automateIncrease productivityDc-dc conversionElectric variable regulationPerformance indexPrinted circuit board

The invention provides an electronic correction chip for circuit parameters of a circuit board. Parameters of a main circuit are adjusted through the correction chip, thereby achieving the correctioneffect on the performance index; pre-connected or pre-disconnected components and other components of the main circuit are welded to the printed circuit board together, and no extra welding or dismounting work is needed, and the correction work can be achieved only by applying voltage excitation in the testing process, thereby achieving the full automation easily, improving the production efficiency, and reducing the cost.

Owner:苏州源特半导体科技有限公司

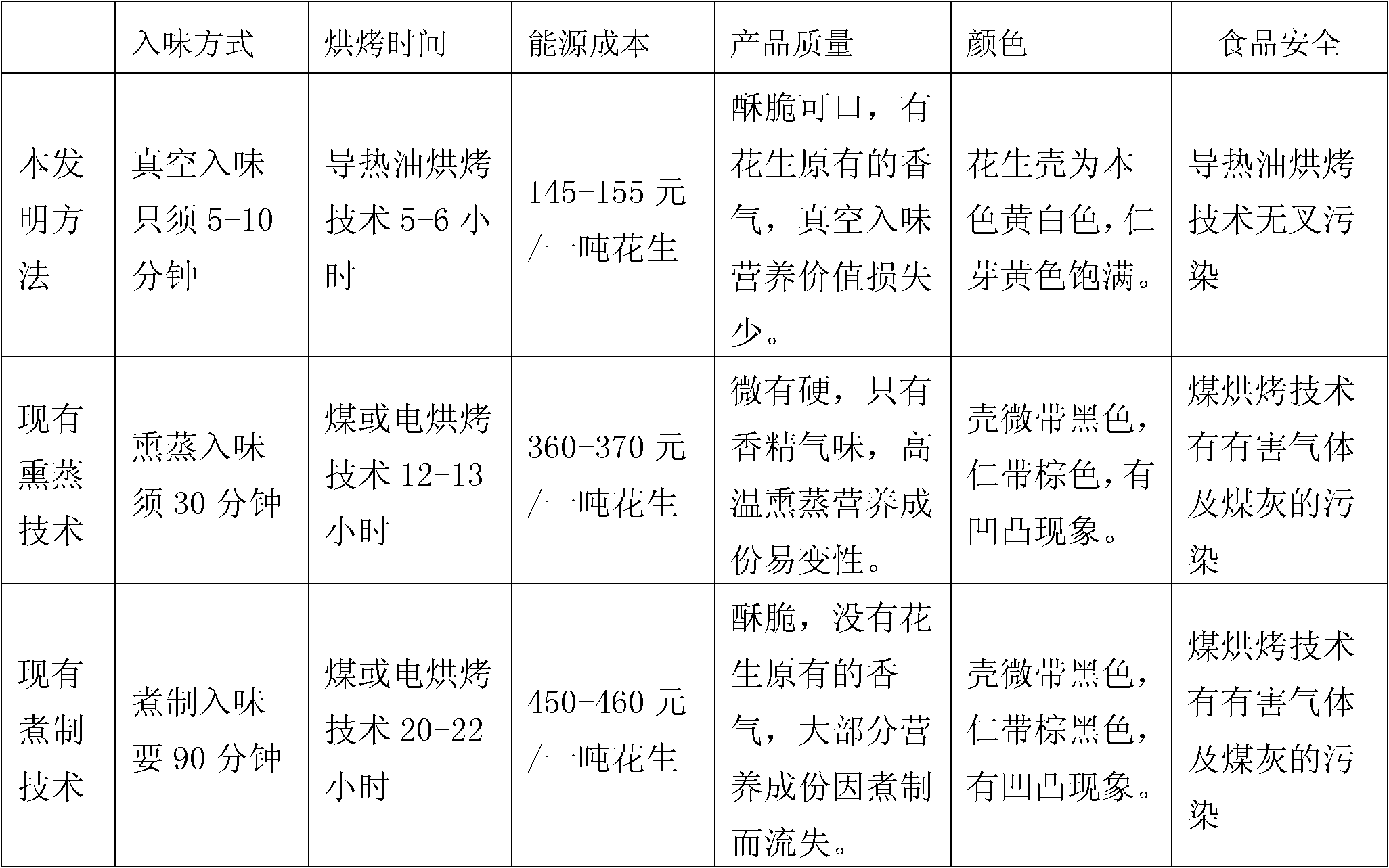

Method for making dried salted peanut

The invention discloses a method for making dried salted peanut. The method comprises the following steps of: cleaning full, bright red and uniform four-grain red peanut, sucking an accessory solution into the peanut kernel by using vacuum negative pressure, leaching the surface of the tasty peanut, baking the peanut by using heat conducing oil as a heat source, cooling, packing, and thus obtaining the dried salted peanut. By the making method, automatic production control is facilitated, the conventional workshop type making mode of the dried salted peanut food is effectively changed into anindustrialized production mode, the quality stability of the dried salted peanut is ensured, the nutritional components of the peanut are reserved, and the peanut made by the method has the advantages of high nutritional value, crisp and delicious taste, lasting aftertaste and the like.

Owner:HUNAN YALIN FOOD

Full-automatic printing press with excellent performance

InactiveCN109016820AExtended service lifeGuaranteed to workCylinder pressesPlaten pressesOperation modePrinting press

The invention discloses a full-automatic printing press with the excellent performance. The full-automatic printing press includes a paper receiving device, a paper feeding device and a second conveying belt, a storage box is arranged at the lower part of the paper feeding device, and a control panel is fixedly mounted on the outer surface of the storage box; and a singlechip is arranged in the paper feeding device, a first conveying belt is arranged on one side of the paper feeding device, an impression cylinder is arranged in the first conveying belt, and a paper transmitting cylinder is arranged at the lower end of the impression cylinder. According to the full-automatic printing press with the excellent performance, a dust-proof thin film, a gravity lubrication device and an ink-feeding assembly are arranged, the small dust and other particles can be prevented from entering the full-automatic printing press, the specific operation can be achieved according to the operation mode setby an operator, the printing automation is achieved, and the lubrication effect is achieved; and meanwhile, the oil ink can be replenished timely, the printing efficiency can be made better, the full-automatic printing press is suitable for different working conditions, and better use prospects are brought.

Owner:沈家洛

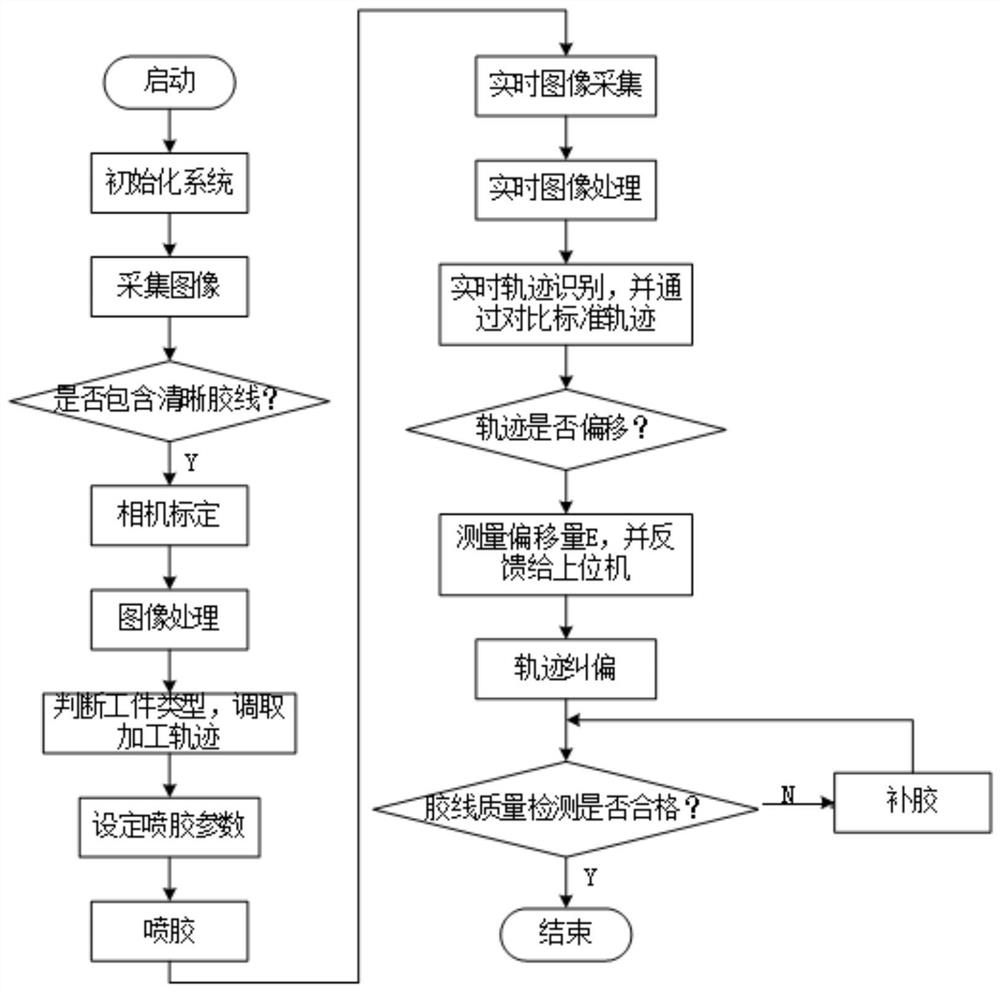

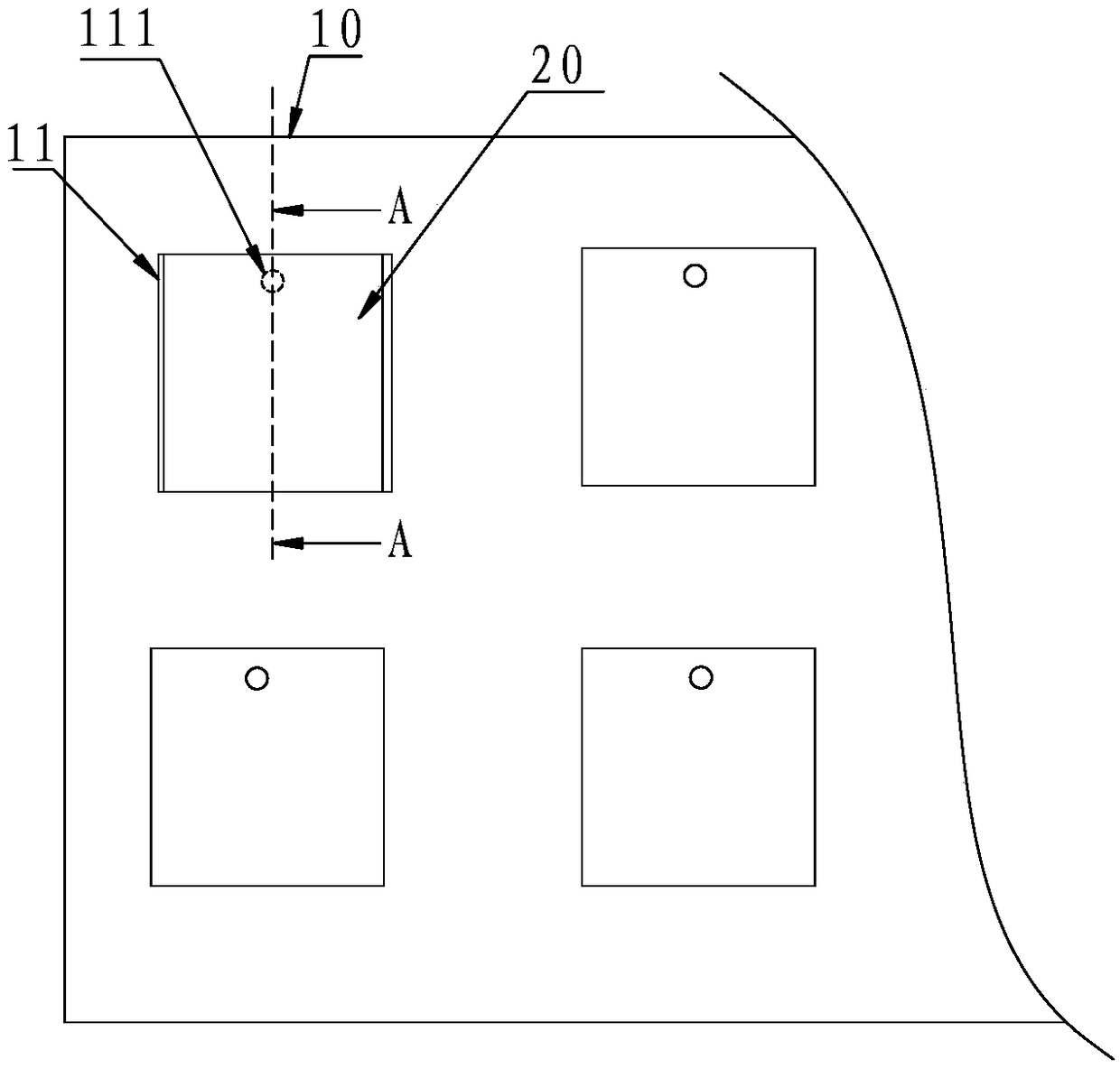

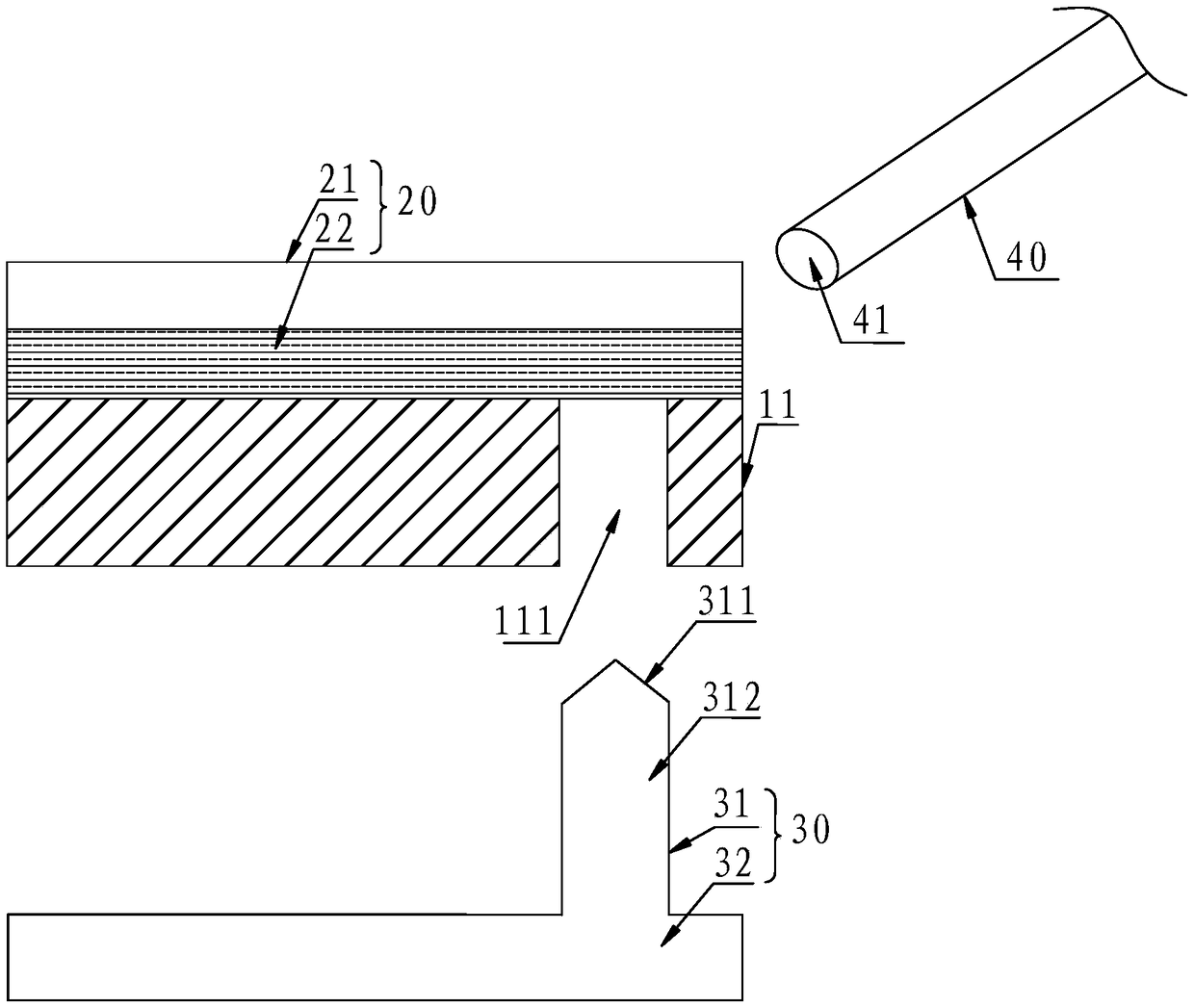

Real-time deviation correction method based on robot gluing

ActiveCN111097664BImprove abilitiesImprove accuracyLiquid surface applicatorsCoatingsProduction lineMachine vision

This invention will provide a real-time deviation correction method based on robot gluing. First, through the complete development of an online visual inspection system for robot gluing quality with both deviation correction functions, it can fill the gap in this field in China, and the equipment is equipped with machine vision online detection. The characteristics of real-time and high precision can improve the efficiency of quality inspection while ensuring the reliability of the inspection results, so as to realize the control of glue quality; secondly, the use of online visual inspection system can reduce the labor cost of the enterprise, improve the inspection efficiency, and make it easy to build Fully automated and intelligent production line. The present invention completely uses the software to automatically compare and judge the real-time gluing curve with the preset standard and simulated ideal trend, instead of manually completing the empirical judgment task, and subdivides the deviation detection part into two comparisons Work, greatly improving the ability and accuracy of detecting deviations.

Owner:广西柳州联耕科技有限公司

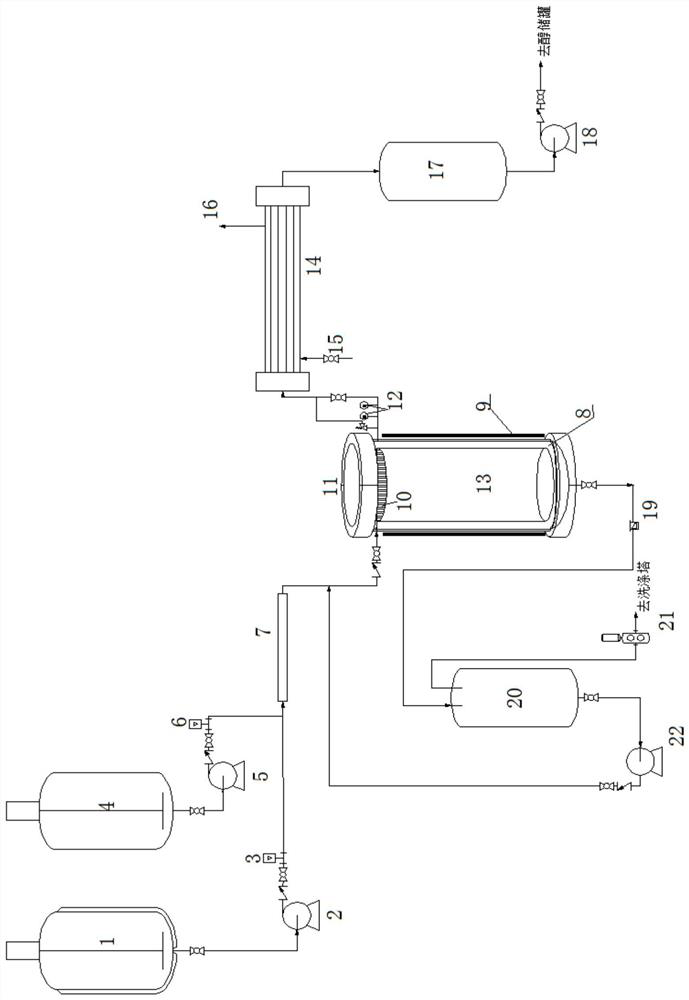

A device for peeling off the protective film layer of electromagnetic film

ActiveCN106379034BEasy to fully automateHigh speedLamination ancillary operationsLaminationProduction lineElectromagnetic shielding

The invention discloses a device for stripping a protective film layer of an electromagnetic film. The device is used for stripping the protective film layer of the electromagnetic film in pressing fit with a film pasting area of an FPC (Flexible Printed Circuit) substrate, and comprises an auxiliary jig and an air injection gun, wherein the auxiliary jig comprises a support base; a film ejecting column capable of penetrating through a locating hole is arranged on the upper surface of the support base; the height of the film ejecting column is larger than the hole depth of the locating hole. The embodiment of the invention provides the device for stripping the protective film layer of the electromagnetic film, and the device replaces manpower for stripping through a blade, so that the stripping speed and the stripping efficiency are greatly improved, meanwhile, the device is low in manufacturing cost and can be re-utilized, and the production cost is reduced indirectly; in addition, the device is simple to operate, can be controlled through a mechanical arm or other control devices, realizes unmanned operation, and is beneficial for full automation of a production line.

Owner:东莞市五株电子科技有限公司

General tooling for headphone production and headphone production method

The invention provides a general tooling for earphone production and a method for producing earphones, wherein the general tooling comprises a bottom plate, an earphone shell placement area arranged on the upper side of the bottom plate in sequence, a wire control card holder and a wire storage board; There is a jack corresponding to the plug of the earphone, and a wire slot is arranged on one side of the wire control card holder; the plug is inserted into the jack, and the wire of the earphone wire is placed in the wire storage board; the wire control of the earphone is placed in the corresponding In the wire control card holder, the shell of the earphone is placed in the earphone shell placement area; the speaker unit of the earphone is assembled and connected with the case and the earphone cable, and the earphone cable connected with the speaker unit is limited in the wiring groove . The use of the above invention can reduce the wear and tear of the appearance of the earphone during the production process of the earphone, save the production time of the earphone, and improve the production efficiency.

Owner:GOERTEK INC

Fully automatic continuous secondary heating device for semi-solid metal billets

The invention relates to a full-automatic continuous type secondary heating device for semisolid metal blanks and belongs to the technical field of semisolid metal processing. The full-automatic continuous type secondary heating device comprises an induction heating power supply, an induction heating mechanism, a material carrying and conveying mechanism, a blank rotating mechanism and an automatic feeding mechanism. The induction heating mechanism comprises seven induction heating coils and a drive device, the induction heating coils are arranged on the drive device, the seven induction heating coils and one vacancy are evenly distributed at 45 degrees in the circumferential direction, and the coils are connected in series and are connected with the induction heating power supply. The blanks are placed on the material carrying and conveying mechanism through the automatic feeding mechanism and sequentially heated by the seven induction heating coils, and the blank rotating mechanism is connected to the material carrying and conveying mechanism, so the blanks can be in a continuous rotation state in the heating process. The full-automatic continuous type secondary heating device can meet requirements for quick heating, even temperature and full-automatic heating in the aluminum alloy semisolid thixotropic processing process and has the advantages of being safe to operate, stable in running and easy to control.

Owner:有研金属复材技术有限公司

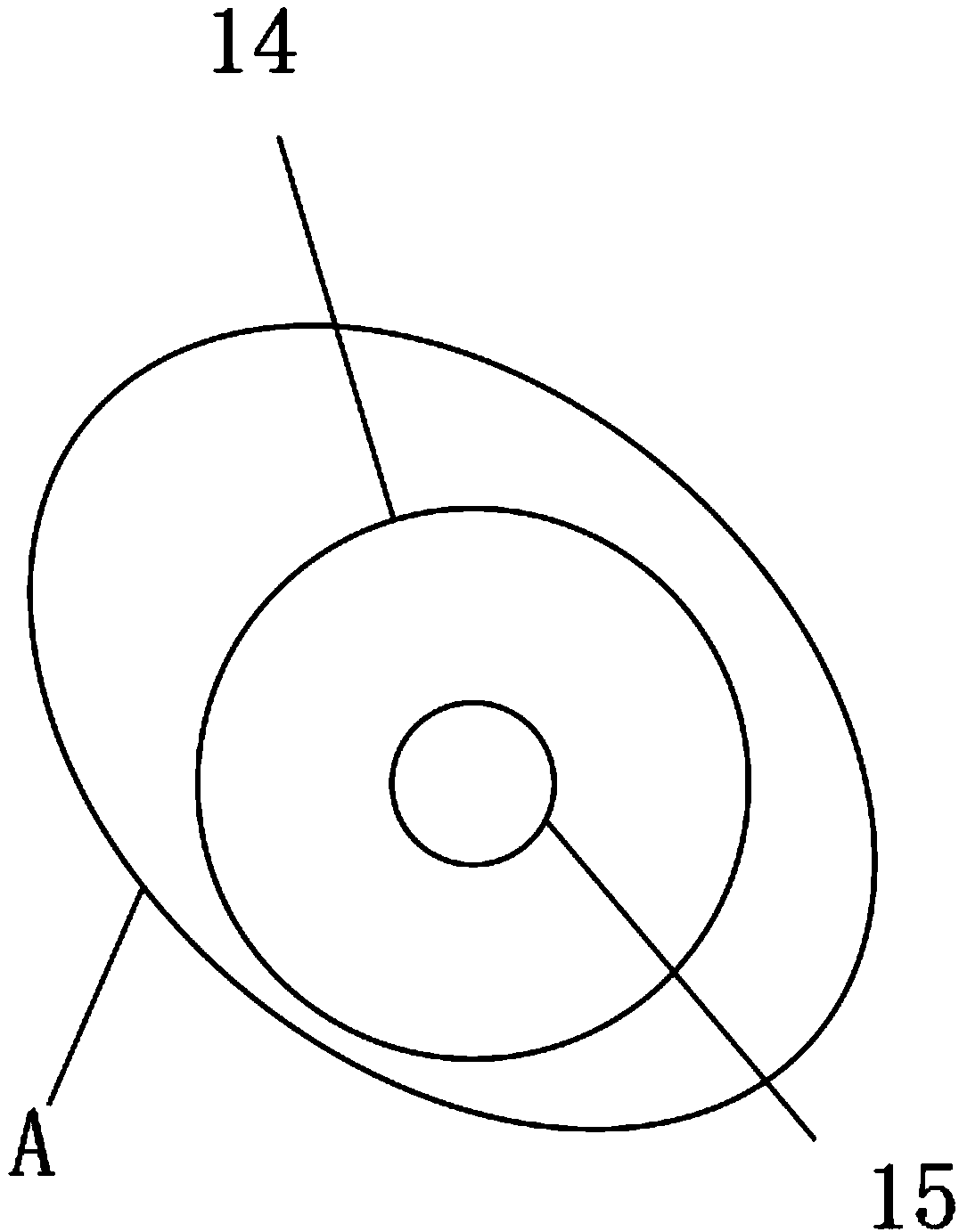

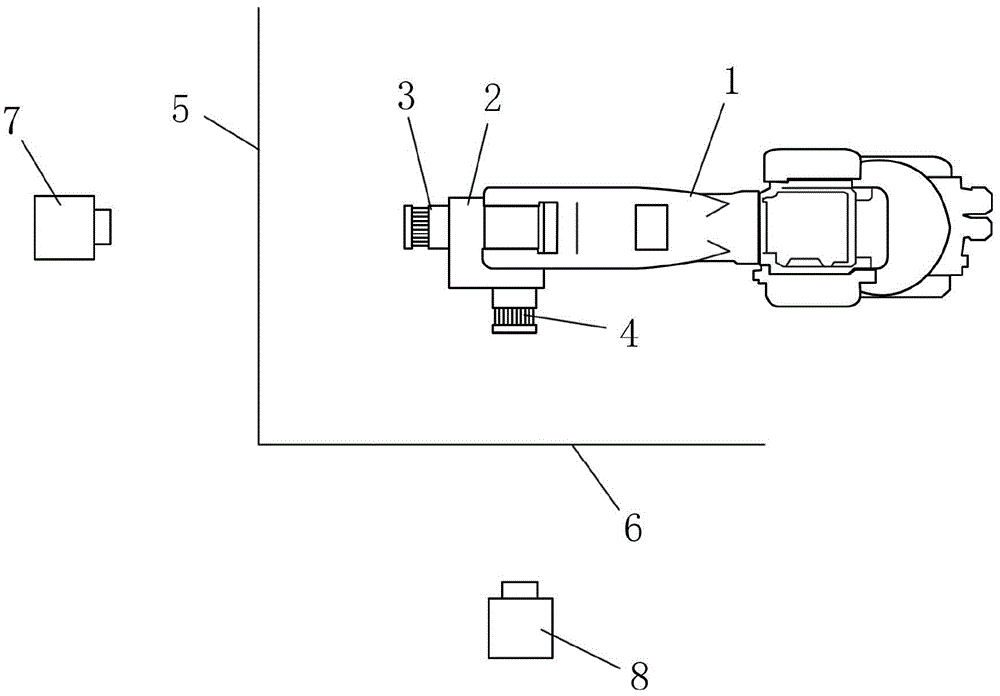

A precision calibration device for a six-joint industrial robot

ActiveCN104197831BEasy to fully automateIncrease brightnessProgramme controlProgramme-controlled manipulatorEngineeringArthrobotrys

The invention discloses a precision calibration device for a six-joint industrial robot. The front of the device one and the light source device two are respectively provided with a projection screen one and a screen two perpendicular to the light source device one and the light source device two, and a camera one and a camera two are respectively placed behind the screen one and the two light source devices; the light source device one and the two The light source device 2 includes a disk, a laser pointer and a fixing piece. Both the disk and the fixing piece have 12 circular holes uniformly distributed on the circumference for installing the laser pointer. The coaxiality of the laser pointer is ≤0.01mm, and the laser pointer The upper and lower ends of the pen are respectively installed on the disk and the fixing piece. Compared with the prior art, the present invention has the following advantages: the precision of the joint robot can be calibrated quickly and at low cost; a laser pen array uniformly distributed on the circumference is used as a light source to form structured light, and the laser has good monochromaticity and good coherence , good directivity, high brightness and other characteristics, which improves the calibration accuracy and reduces the cost of the system.

Owner:SICHUAN UNIV

Nucleic acid purification method for DNA methylation analysis of human stool

ActiveCN109439726BImprove conversion rateQuality improvementMicrobiological testing/measurementDNA methylationSulfite salt

Owner:SHANGHAI REALBIO TECH CO LTD

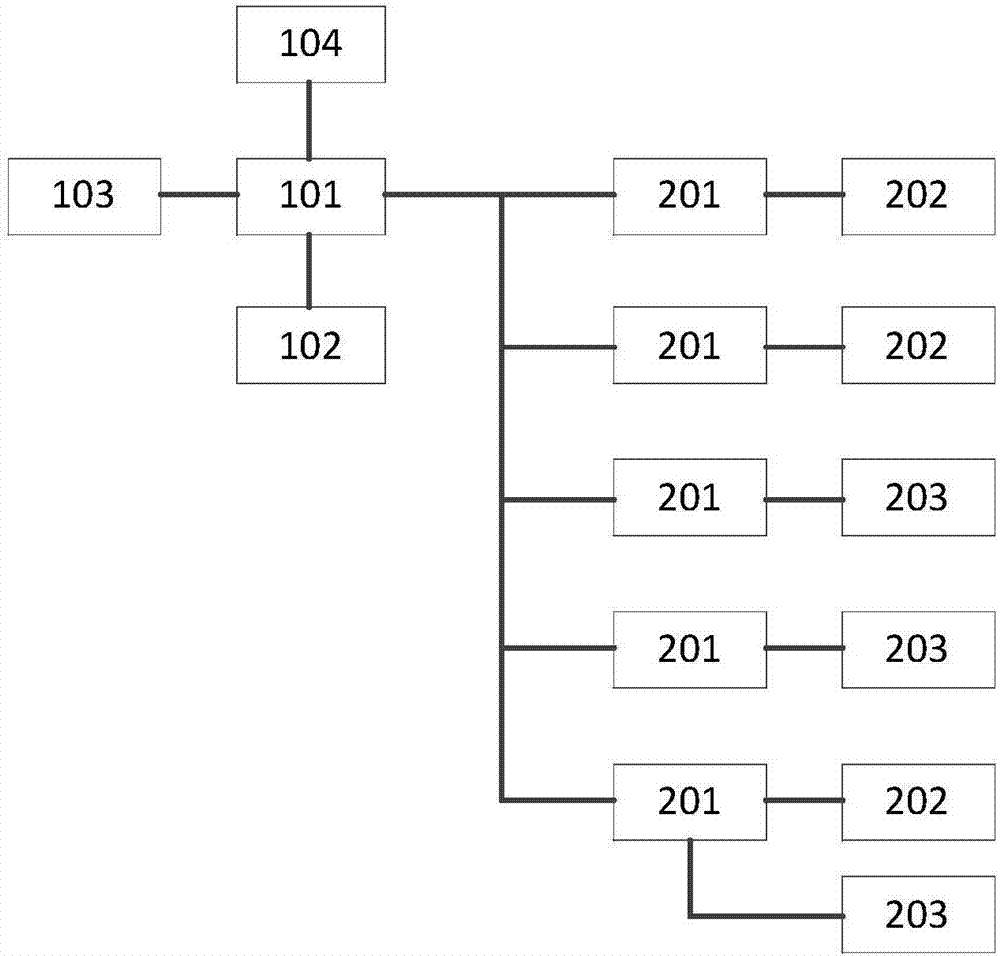

Multifunctional dismountable type ground heating floor control system

InactiveCN107976931AVersatileImprove scalabilityProgramme controlMeasurement devicesControl systemAgricultural engineering

The invention provides a multifunctional dismountable type ground heating floor control system. The system comprises center control, human-machine interaction, a water heater and a water suction pump.The center control is connected with and controls the human-machine interaction, the water heater and the water suction pump, and is also serially connected with multiple floor chips through buses. The floor chips are connected with one or two kinds of combinations of a sensor group and an operator group. According to the invention, the system is applied to multifunctional dismountable type ground heating floors; the ground heating floors are enabled to provide various functions; the system is highly expandable and convenient to operate and use; it is easy for users to accept the system; andfull automation of the smart home is facilitated.

Owner:贵州众暖科技开发有限公司

Automatic computer host detection device

PendingCN113074771AEasy to fully automateMeet the needs of detection from different anglesMeasurement apparatus componentsEngineeringWorkbench

Owner:CHINA THREE GORGES UNIV

Deformation analyzer of barrel body

InactiveCN1178043CImprove stabilityImprove reliabilityRolling contact bearingsMaterial analysis by optical meansMicrometerLaser scanning

Owner:MINEBEA CO LTD

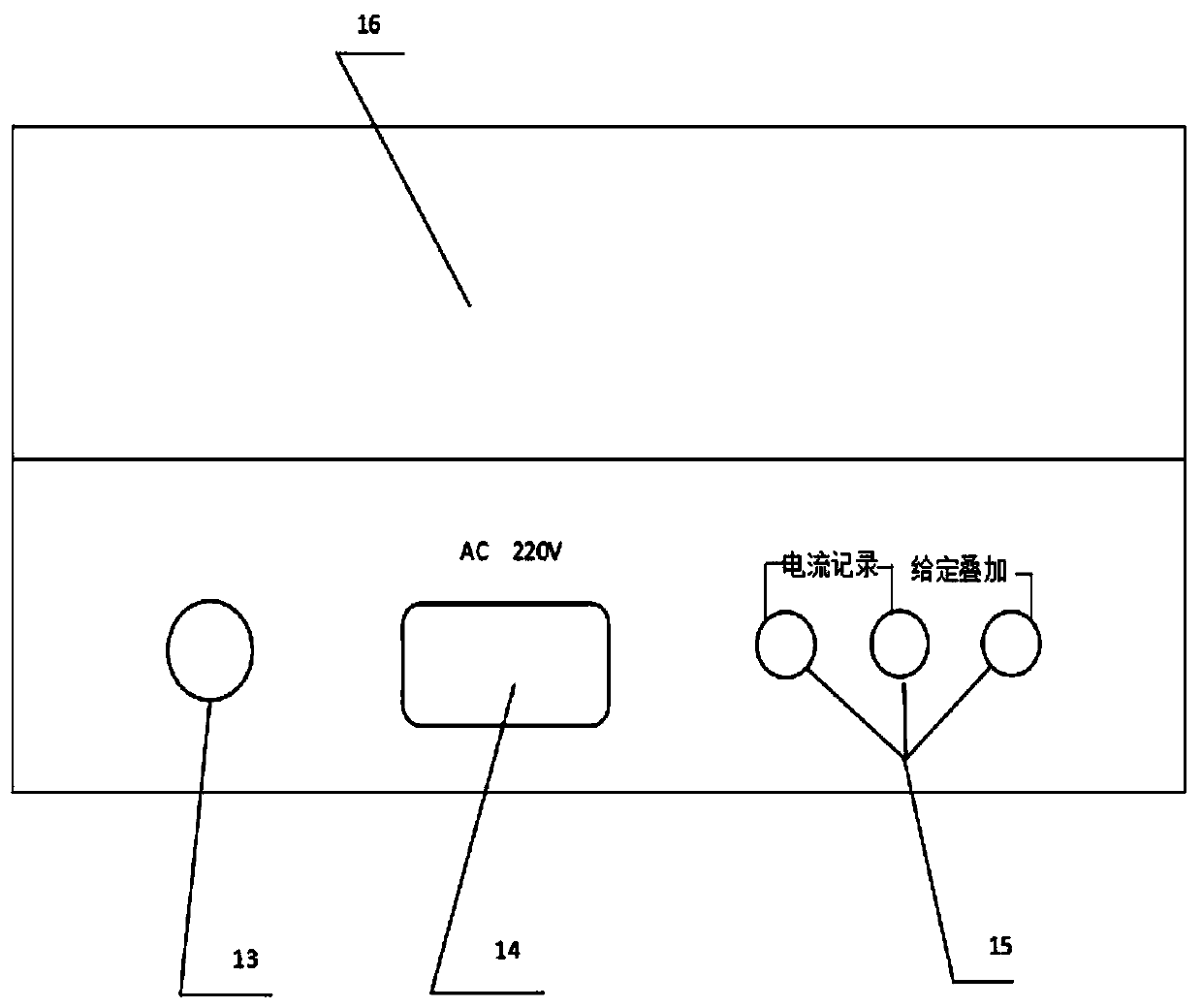

Electrochemical method and device for sorting structural steel grades

ActiveCN107607606BAchieve the purpose of sortingLow costMaterial electrochemical variablesLiquid-crystal displayHemt circuits

An electrochemical method and device for sorting structural steel grades. The main purpose is to provide an electrochemical method capable of quickly and accurately sorting structural steel grades and a device for realizing the method. It is characterized in that: the main step of the method is to measure and obtain the anodic polarization curve of the unknown brand structural steel in a special electrolyte solution by performing electrochemical experiments on the structural steel of the unknown brand, and analyze the characteristic parameters of the anodic polarization curve, and then Compared and identified with the standard anodic polarization curve characteristic parameters of known grades of structural steel in the standard sample database, the grade of the steel is finally identified; the device includes an electrochemical test module and a polarization curve identification module; the electrochemical The test module includes a three-electrode electrolytic cell, a test circuit and a motor stirring circuit; the polarization curve identification module includes an 89C51 chip, an analog-to-digital conversion chip and a liquid crystal display circuit.

Owner:NORTHEAST GASOLINEEUM UNIV

How to make a honeycomb structure

ActiveCN109848558BAvoid deformation effectsContinuityExhaust apparatusSilencing apparatusStructural engineeringMechanical engineering

Owner:BEIJING ANDER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com