Aluminum pig casting machine

A casting machine and aluminum ingot technology, applied in foundry workshops, casting equipment, ingot casting workshops, etc., can solve the problems of manual adjustment of slagging, bundling, low work efficiency, and irregular stacking, etc. Cost saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

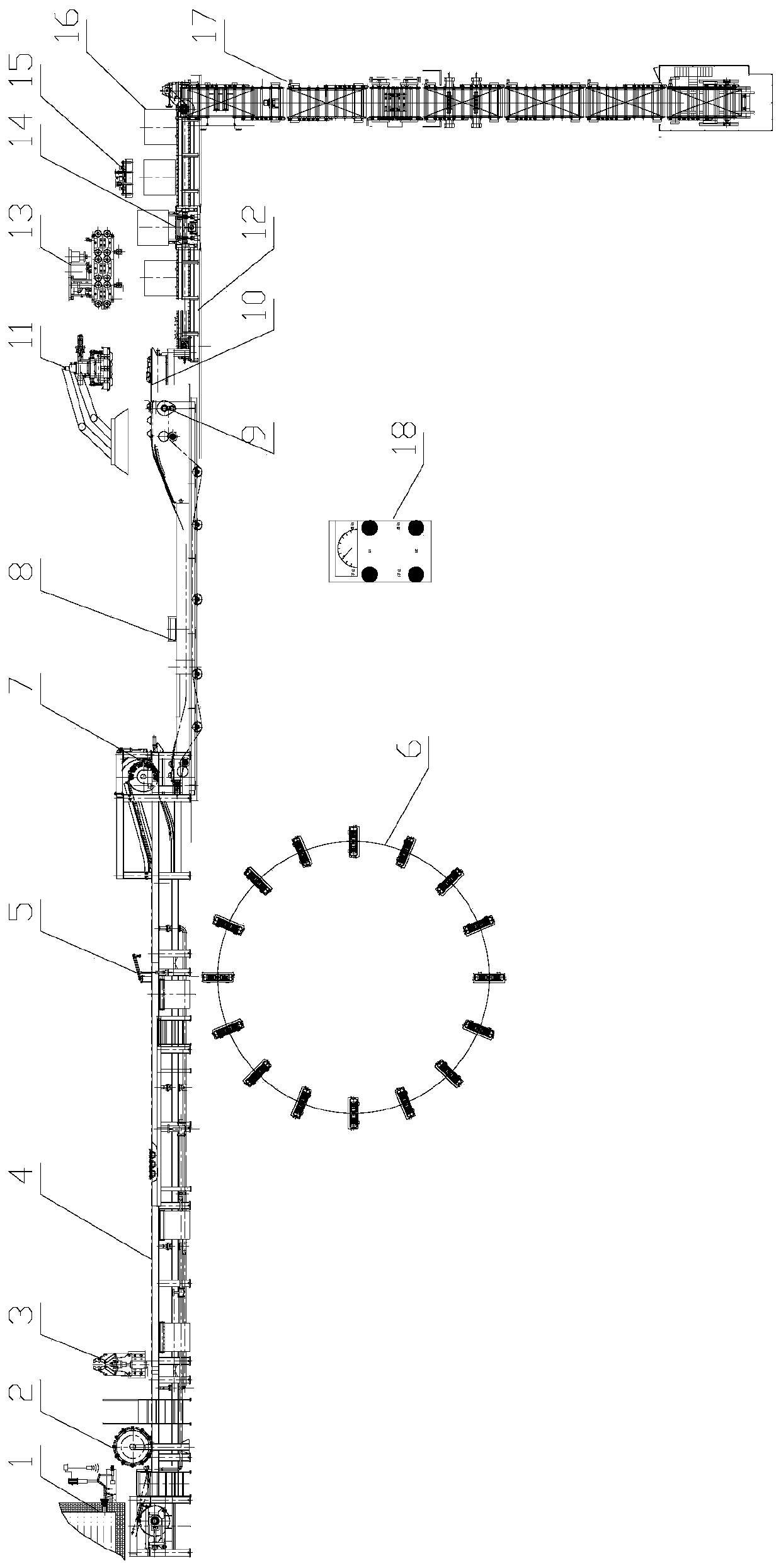

[0027] like figure 1 As shown, the aluminum ingot casting machine of the present invention includes an automatic aluminum water flow adjustment device 1, an aluminum liquid distribution system 2, a robot slag breaking machine 3, a horizontal casting machine 4, an aluminum ingot marking machine 5, and a disc Ingot receiving conveyor 6, electric chain ingot supporting device 7, cooling conveyor 8, aluminum ingot turning device 9, alignment conveyor 10, stacking robot 11, finished product conveyor 12, automatic strapping machine 13, online weighing device 14. Aluminum ingot stacking laser marking machine 15, storage plate chain 17 and electrical control system 18.

[0028] The aluminum water flow automatic adjustment device 1 includes a servo system, a detection device and an adjustment device. The function is to control the weight of the aluminum ingot by controlling the liquid level, realize automation, break the manual inaccurate control method, reduce hidden dangers, save tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com