Floating type automatic sucker rod screwing on and off device

A sucker rod, floating technology, applied in drill pipe, drilling equipment, earthwork drilling, etc., to achieve the effect of reducing quantity, high degree of integration, and reducing personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

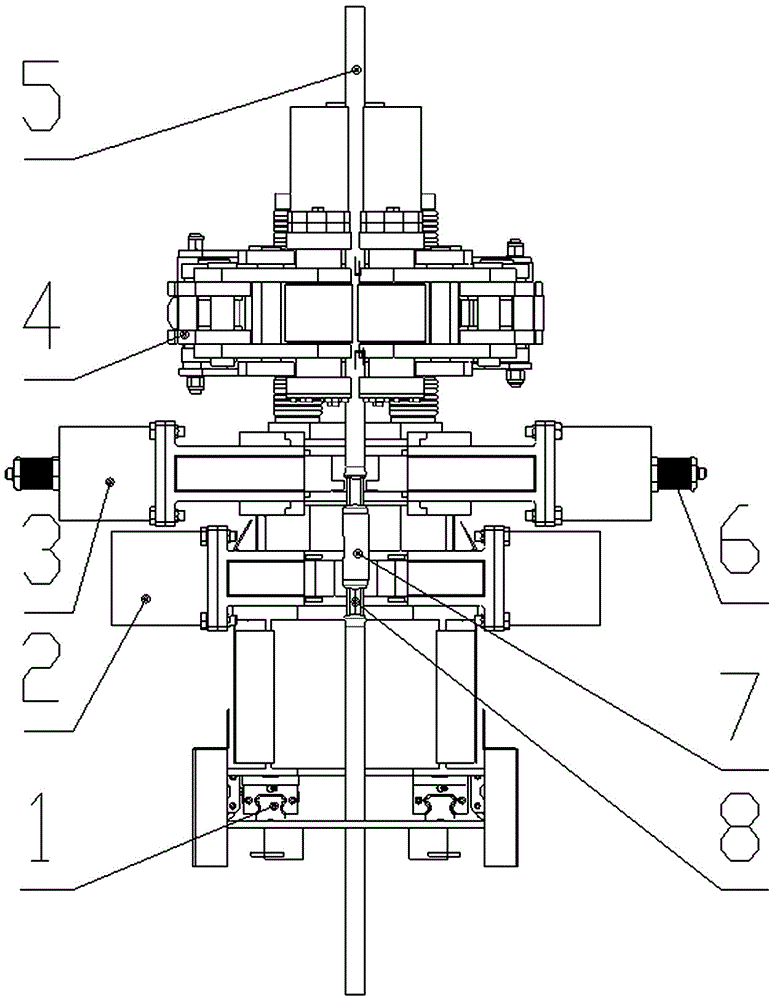

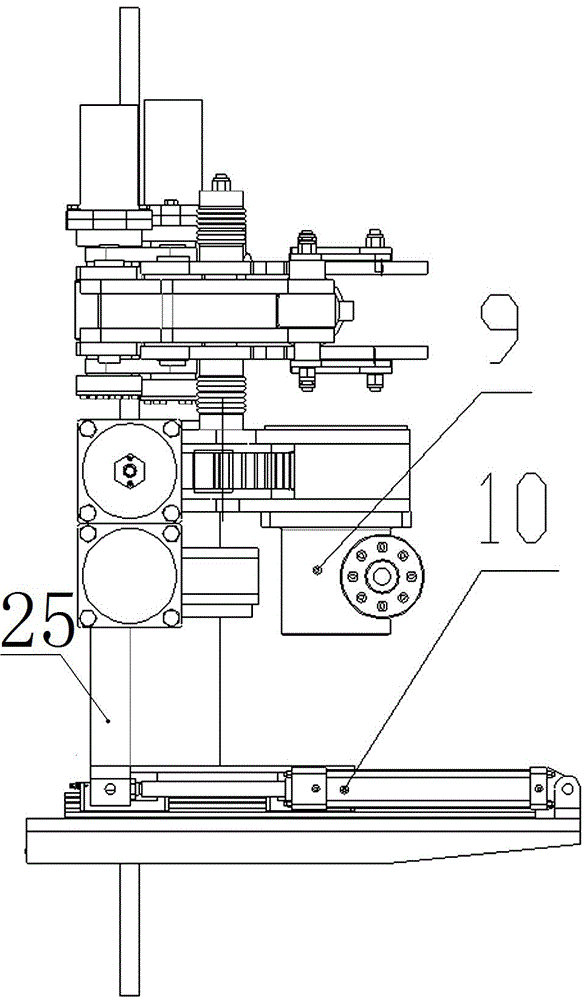

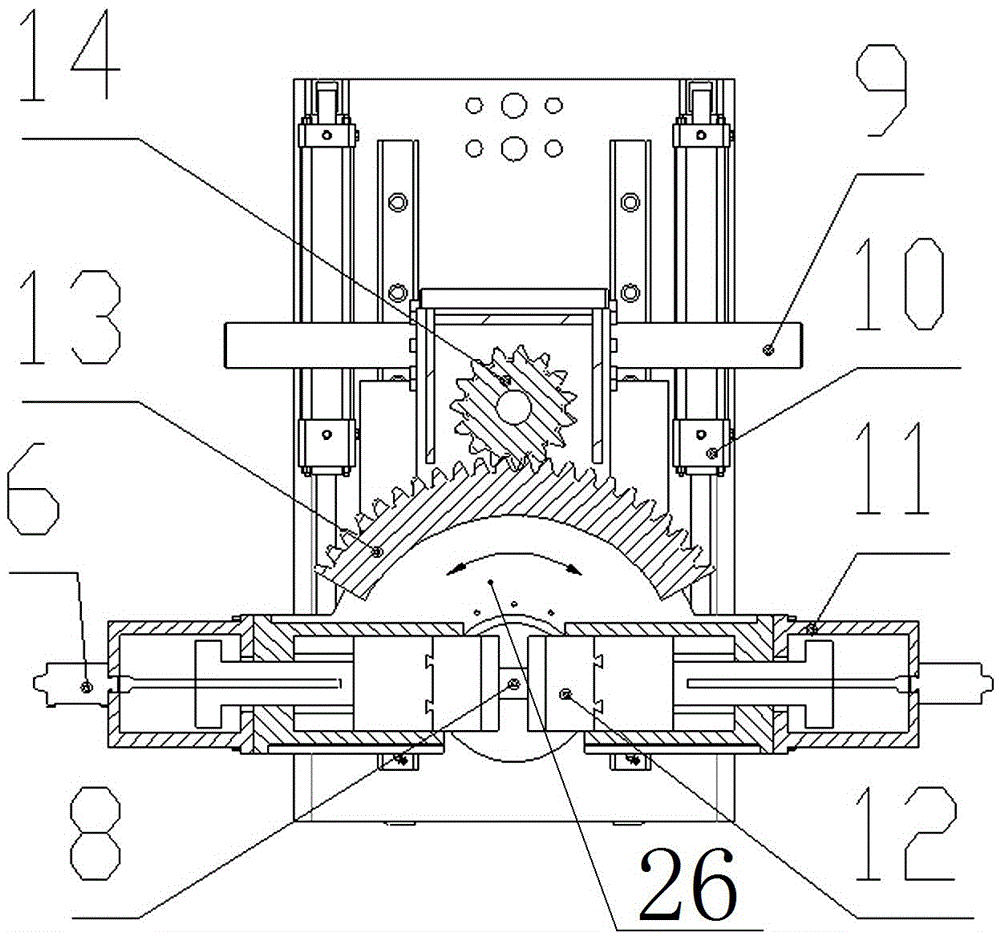

[0029] see Figure 1-6 , a floating sucker rod automatic on-off device, comprising a bracket 25, a guide rail 1, a back-up tong 2, a moving tong 3 and a rotating tong 4, wherein the back-up tong 2 and the moving tong are coaxially installed on the bracket 25 sequentially from bottom to top 3 and the rotary tong 4, the bracket 25 is installed on the guide rail 1 and moves laterally through the guide rail oil cylinder 10 installed on the guide rail 1; Reverse torque; the movable tongs 3 are used to clamp the wrench side of the second sucker rod and realize buckling and buckling. It includes a base and a clamping unit and a rotating unit installed thereon. The clamping unit includes a rotating seat 26 and The movable tong cylinder 11 installed on it and the tooth plate 12 driven by the movable tong cylinder 11 to move relatively laterally, the movable tong cylinder 11 is equipped with a displacement sensor; the swing unit includes a swing cylinder 9, a pinion 14 and a half ring g...

Embodiment 2

[0032] see Figure 1-6, a floating sucker rod automatic on-off breakout device, on the basis of Embodiment 1, the rotary tongs clamping cylinder 18 controls the rollers of each rotary tong to move closer to or away from each other through the linkage mechanism 17; the linkage mechanism 17 includes a fixed seat 19. Two movable seats 20 and connecting rod groups, the two movable seats 20 are respectively symmetrically installed on both sides of the fixed seat 19 through the connecting rod groups; wherein each connecting rod group includes a first connecting rod 21 and a second connecting rod 22. The first connecting rod 21 and the second connecting rod 22 are two arranged side by side; the middle part of the first connecting rod 21 is hinged to one side of the fixed seat 19, and the first end of the first connecting rod 21 is connected to the rotary clamp The clamping oil cylinder 18 is hinged, the second end is hinged with the outside of the movable seat 20, the first end of th...

Embodiment 3

[0035] see Figure 1-6 , a floating sucker rod automatic on-off device, on the basis of Embodiment 2, the first ends of the first connecting rods 21 connected to the two movable seats 20 are respectively hinged with third connecting rods 23 The other ends of the two third connecting rods 23 are connected at a certain angle relative to each other through a pin shaft; the fixed base 19 is fixed with a V-shaped fork body 24, and the pin shaft is located in the V-shaped fork body 24 and can move along it and be limited.

[0036] The working process is basically the same as that of Embodiments 1 and 2, and only the working process of the above-mentioned added structure will be described below. When the clamping cylinders 18 of the rotary tongs extend to both sides, the two third connecting rods 23 also move outwards respectively. Move, the angle between the two third connecting rods connecting rods 23 gradually increases until the two become a straight line, at this time it can con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com