A precision calibration device for a six-joint industrial robot

A technology of industrial robots and calibration devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor spatial positioning accuracy of industrial robots, inability to calibrate point attitude parameters, and inability to realize rapid automatic calibration, etc., to achieve reduced calibration Difficulty, low cost, and the effect of improving calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

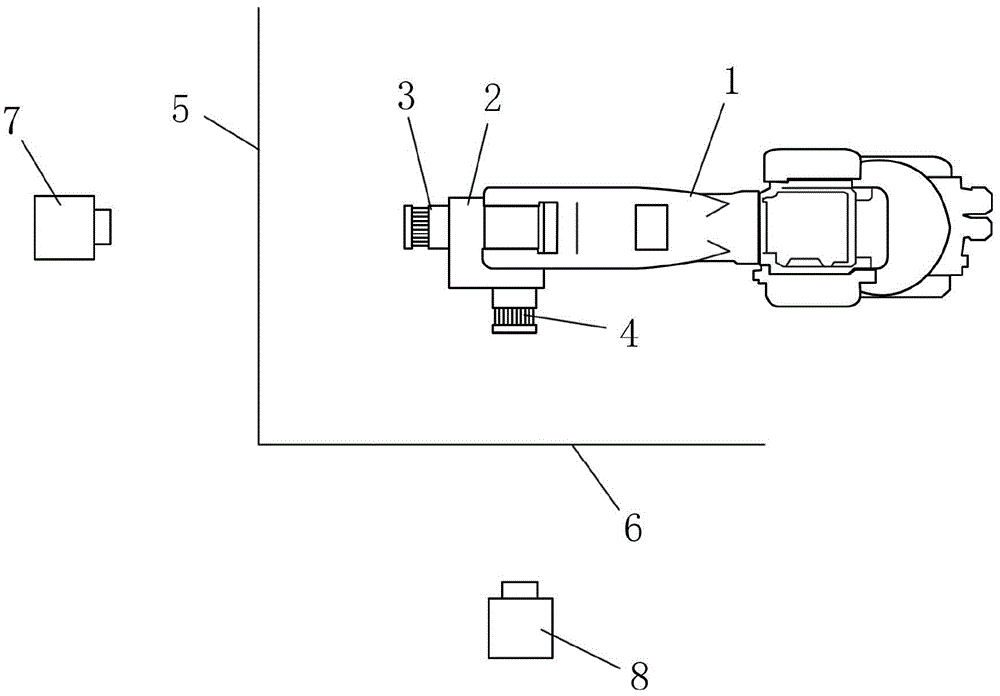

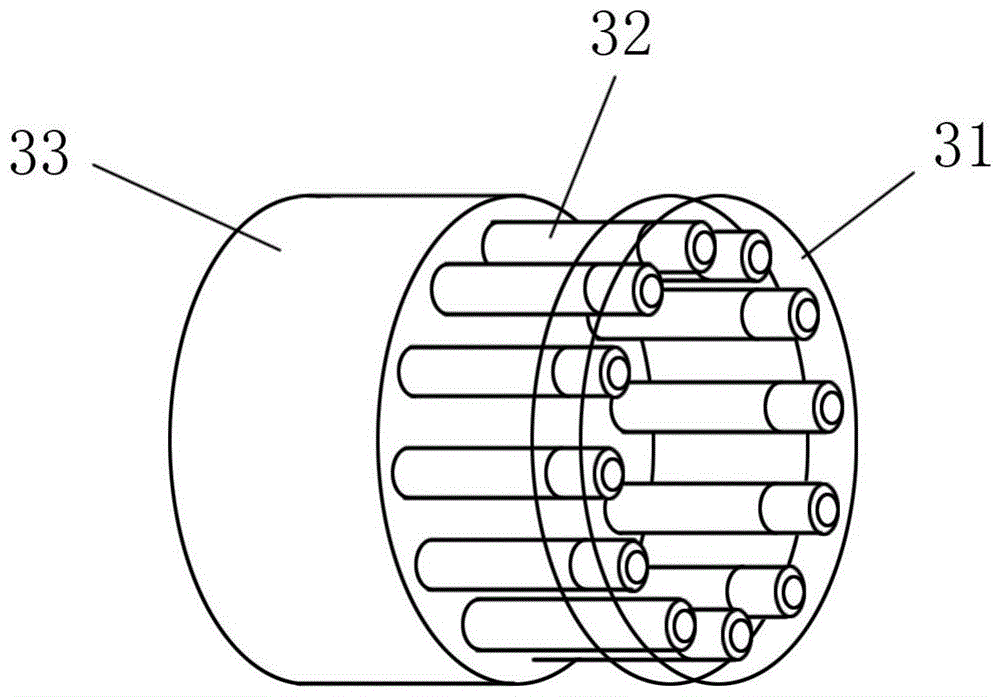

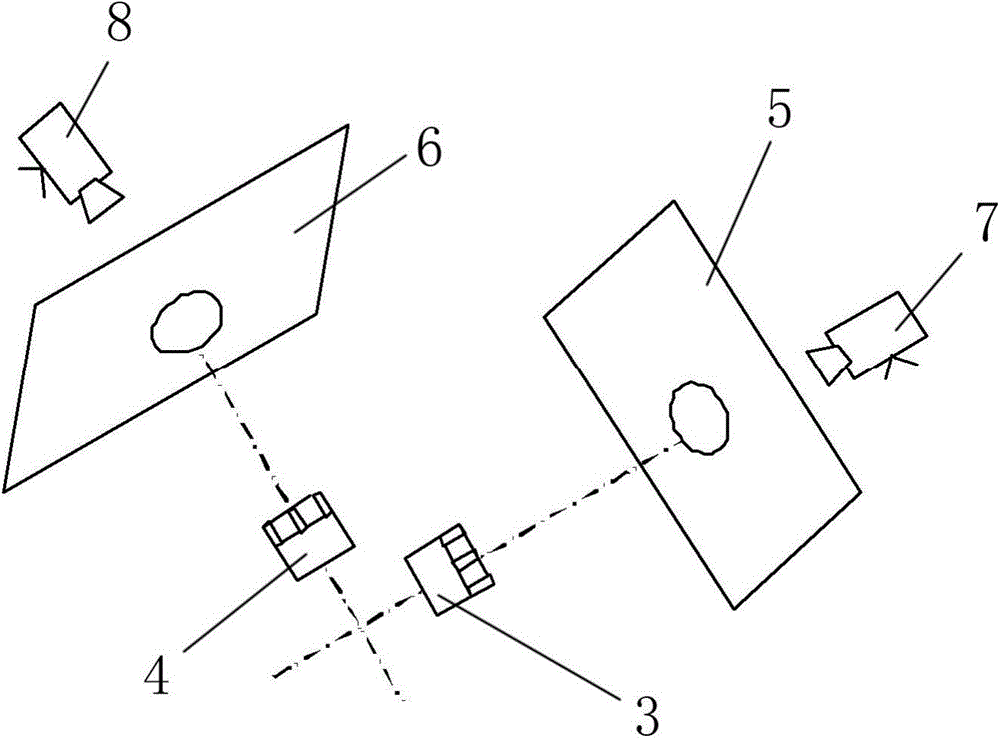

[0018] Such as figure 1 , figure 2 and image 3 As shown, a precision calibration device for a six-joint industrial robot includes a six-joint industrial robot 1, a connector 2 is connected to the end of the six-joint industrial robot 1, and a light source device 1 3 and a light source device 2 are fixed on the connector 2 4. In front of the light source device 1 3 and the light source device 2 4, projection screen 1 5 and screen 2 6 perpendicular to the light source device 3 and light source device 2 4 are arranged respectively, and the rear of the screen 1 5 and screen 2 6 are respectively placed A camera one 7 and a camera two 8 are arranged; the light source device one 3 includes a disc 31, a laser pointer 32 and a fixing member 33, and the disc 31 and the fixing member 33 all have 12 circular holes uniformly distributed in the circumferential direction, It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com