Chip cutting control method and system, equipment and computer readable storage medium

A control method and chip technology, applied in computing, semiconductor/solid-state device manufacturing, image data processing, etc., can solve the problems of deviation in cutting process, labor cost, impact of knife accuracy, etc., to improve accuracy, improve production efficiency, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In this embodiment, the artificial intelligence-based chip dicing tool calibration method and device are taken as an example, and the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

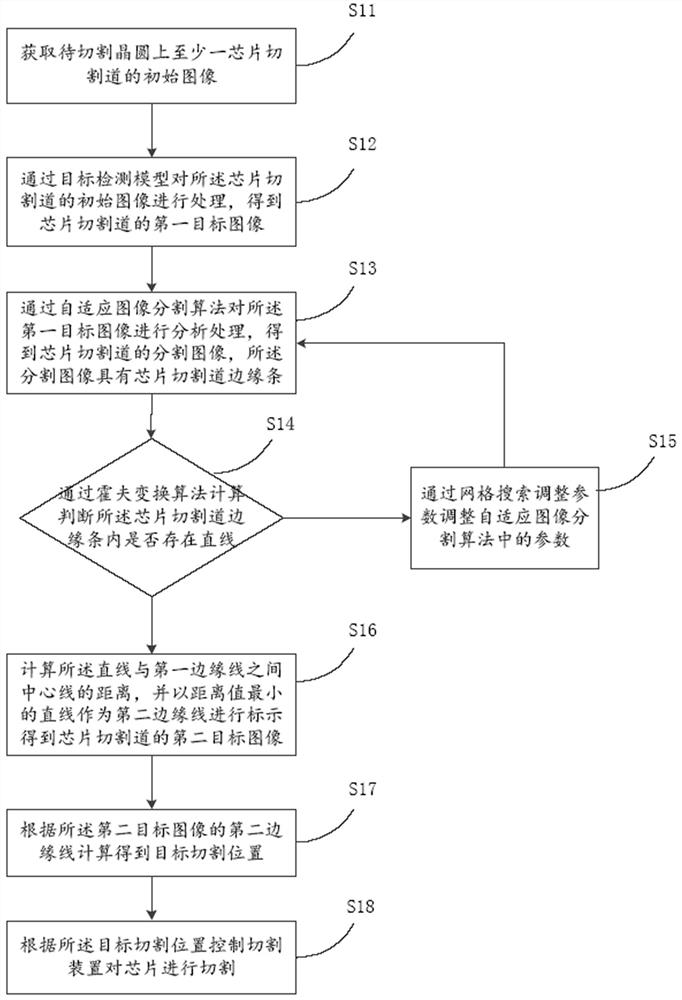

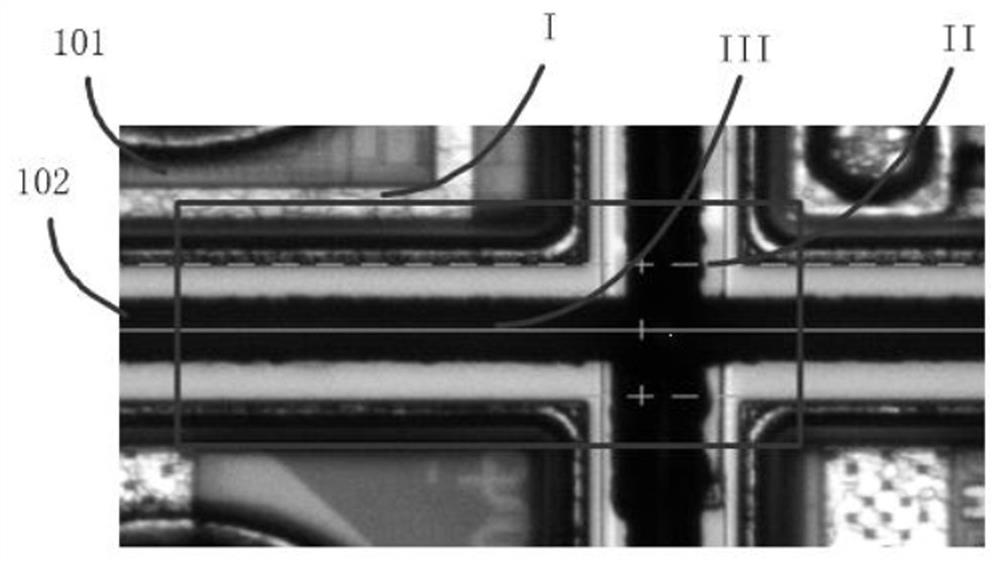

[0049] A chip dicing control method provided by an embodiment of the present invention includes the following steps: acquiring an initial image of at least one chip dicing line on a wafer to be diced; the chip dicing line is a gap between adjacent chips arranged along a predetermined direction ; The initial image of the chip dicing line is processed by the target detection model to obtain a first target image of the chip dicing line, and the first target image has a first edge line of the chip dicing line; for the first target image Perform edge line positioning analysis to obtain a second target image of the chip dicing line, the second target image has a second edge line of the chip dicing line, and the error between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com