Coking and coal blending method with participation of fat coal

A technology for coking coal and fat coal, used in coke ovens, petroleum industry and other directions, can solve the problems of low metamorphism and non-compactness, and achieve the effect of reducing the cost of coal blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

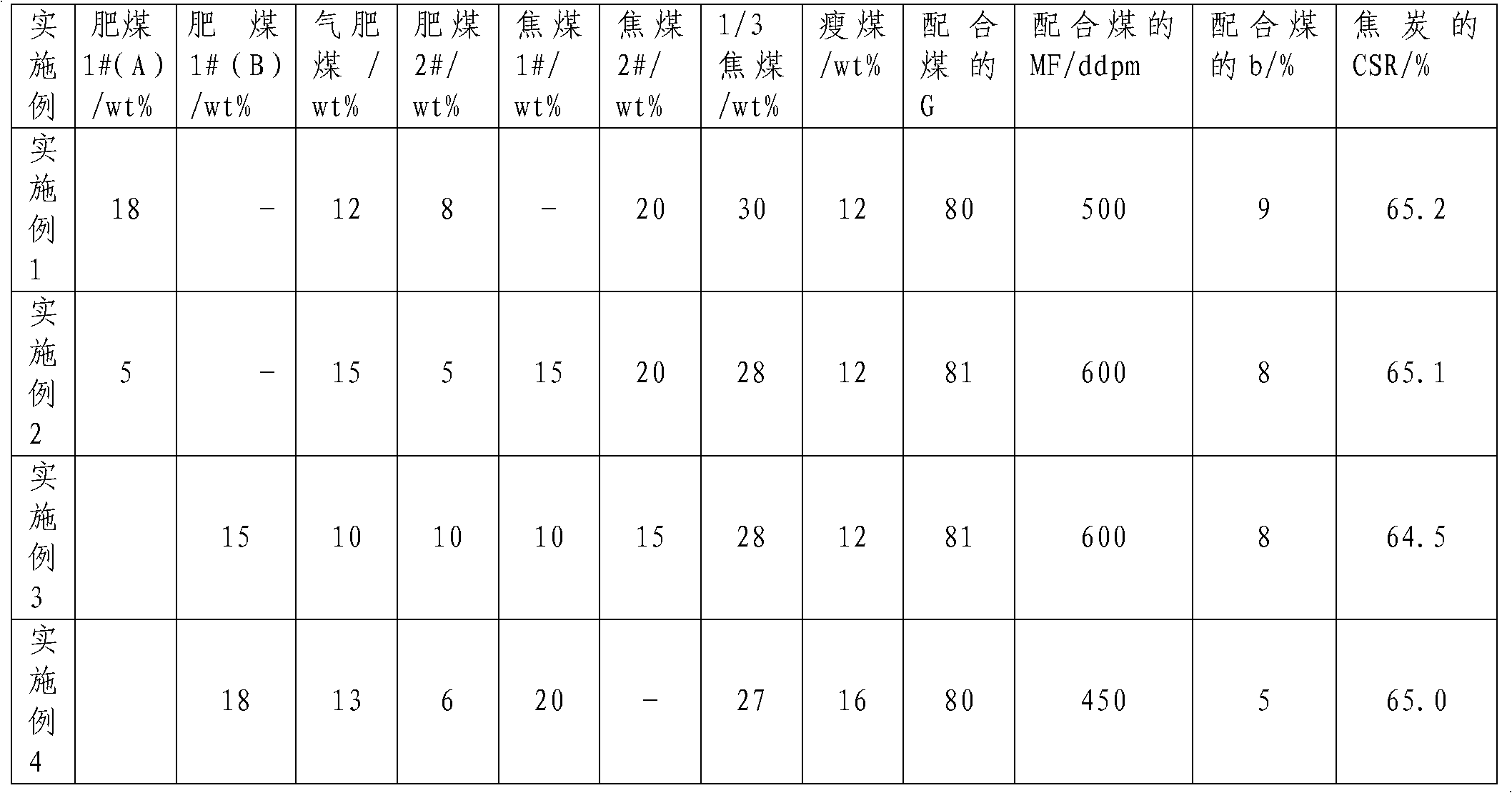

[0008] The present invention will be described in further detail below in combination with specific embodiments.

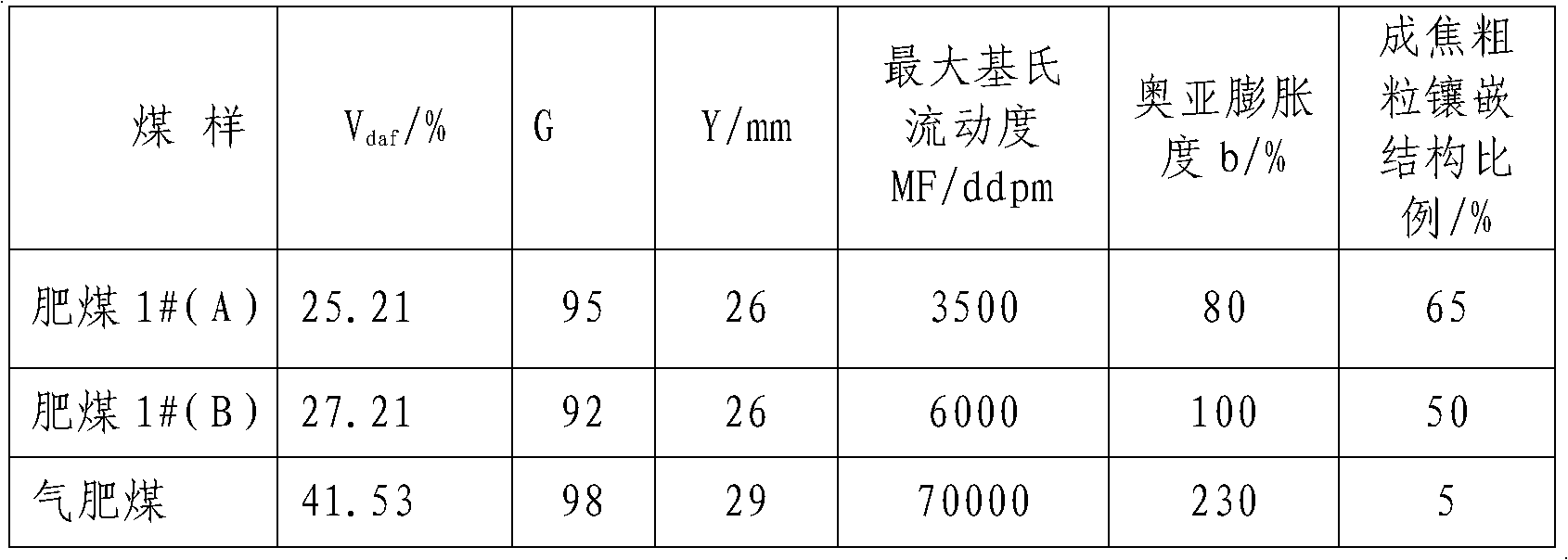

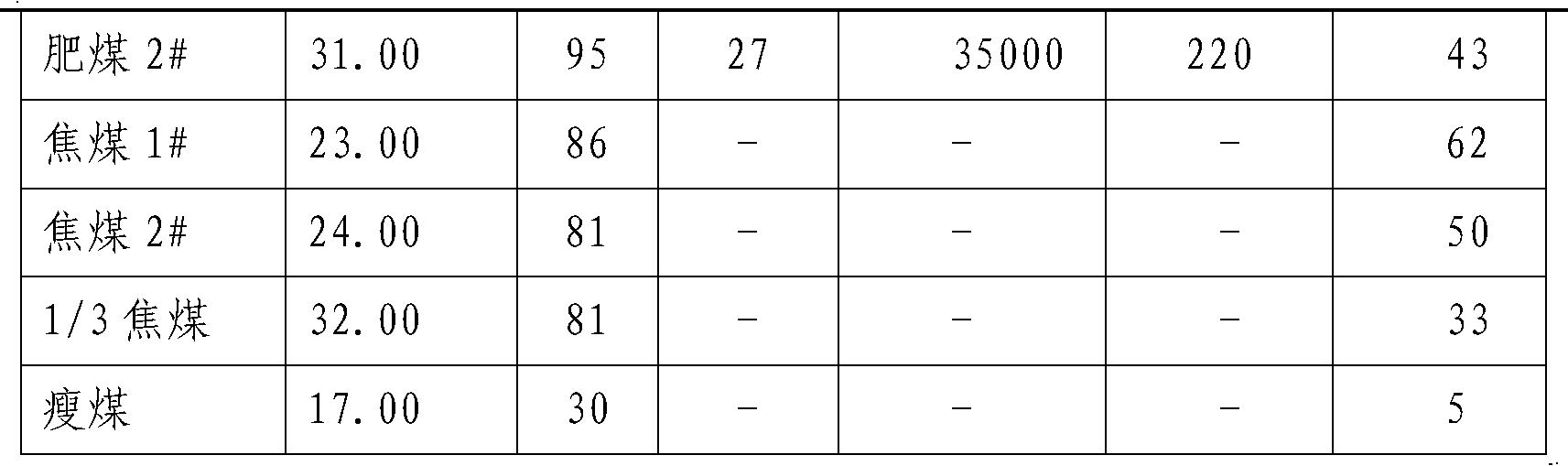

[0009] Coking coal blending method of the present invention, at first measure the single coal of fat coal 1# and become coke coarse-grain mosaic structure, the dry ash-free base volatile matter V of described fat coal 1# daf 25mm, maximum Gibbs fluidity MF<10000ddpm, the proportion in the blended coal is 5-20wt%, and the following coal blending steps are adopted:

[0010] The first step: colloid dilution raw material selection: choose the gas-fertilized coal with the maximum Gibbs fluidity MF > 60000ddpm, b value > 220%, and rich colloid.

[0011] The second step: add gas fat coal so that its proportion in the blended coal is 10-15wt%, and correspondingly reduce the proportion of fat coal 2# so that its proportion in the blended coal is not higher than 10wt%, so as to dilute Colloid with coal.

[0012] The third step: According to the coarse-grain mosaic structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion index | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com