Hexagon nut

A technology of hexagonal nuts and nut bodies, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of reducing production efficiency, affecting maintenance efficiency, rusting of hexagonal nuts and bolts or screw rods, etc., to increase production efficiency, The effect of reducing downtime and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

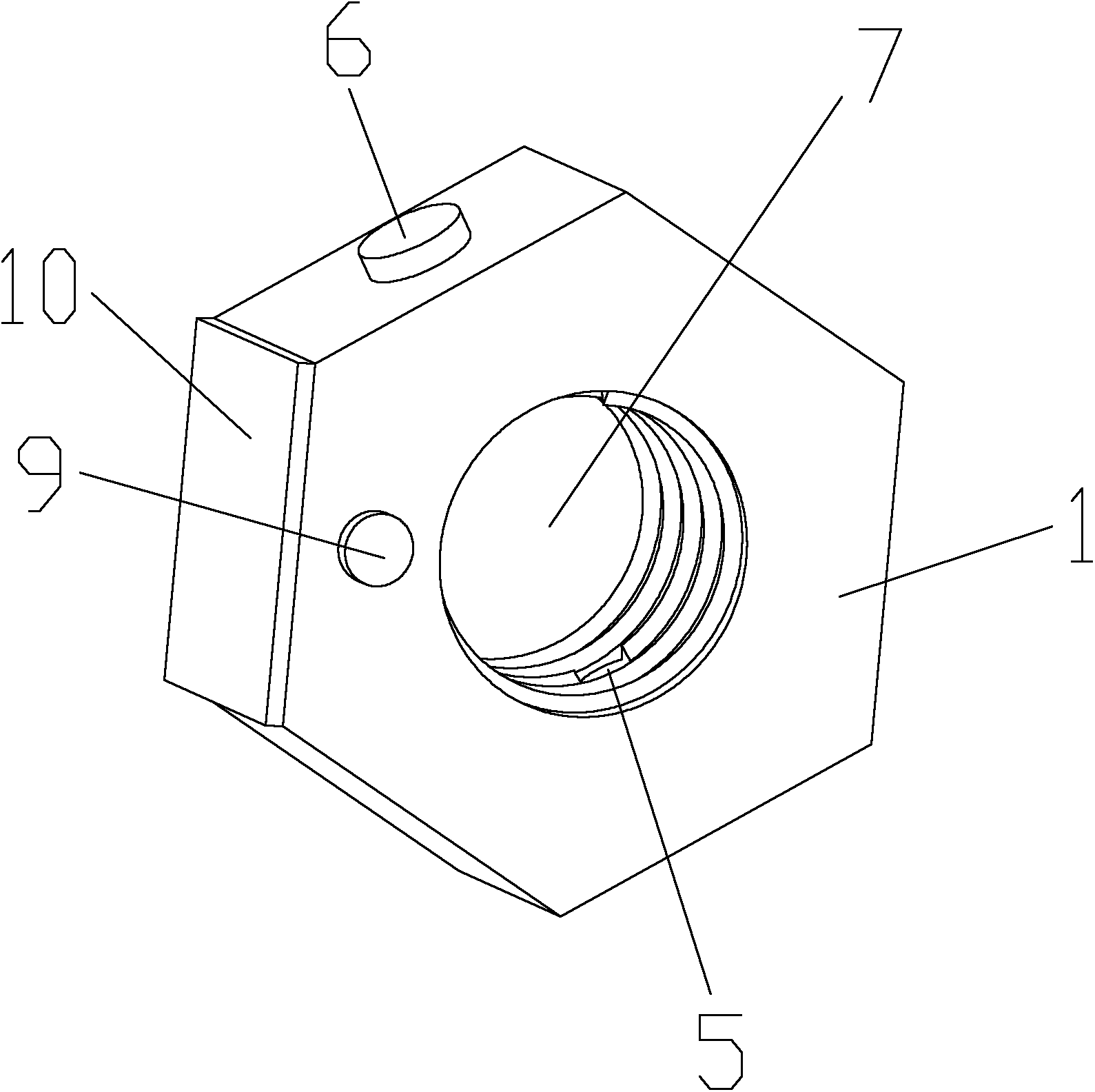

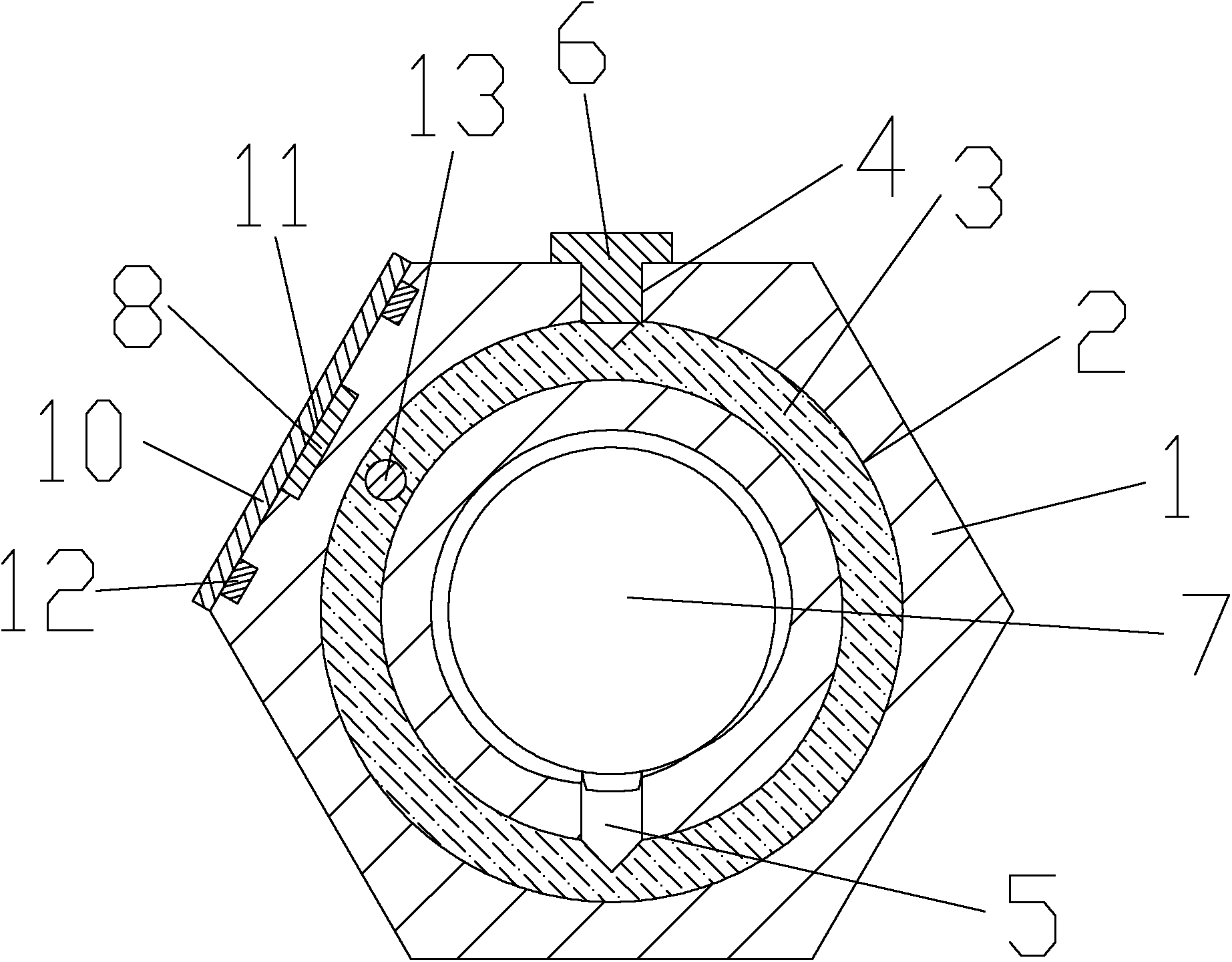

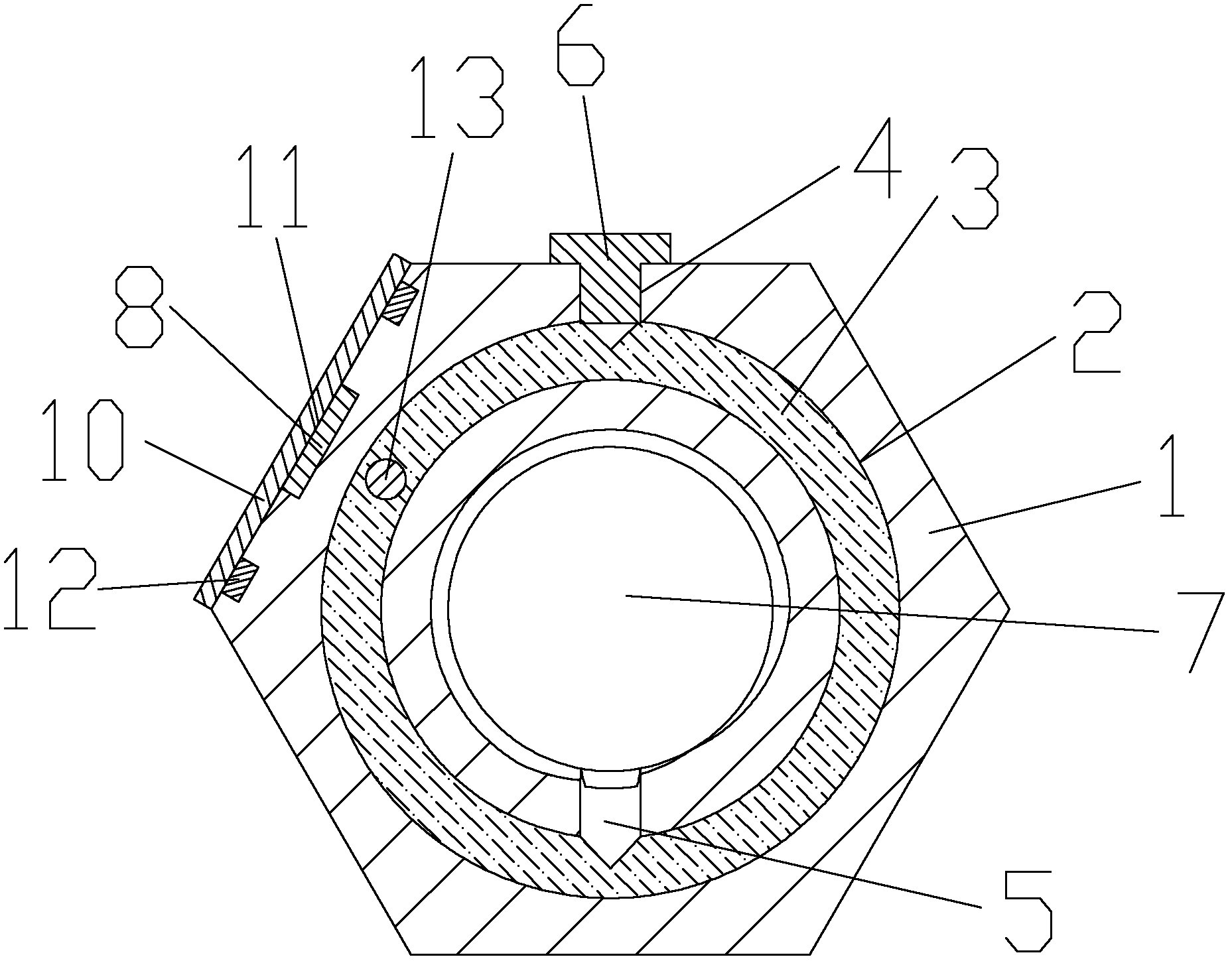

[0016] as attached figure 1 , 2 The hexagonal nut of the present invention shown includes a nut body 1, and an oil groove 2 is arranged in the nut body 1; the oil groove 2 is in the shape of a ring; solid lubricating oil 3 is filled in the oil groove 2; The nut body 1 is also provided with an oil injection hole 4 and an oil outlet hole 5; the oil injection hole 4 communicates with the outside world; the oil injection hole 4 is provided with a plug 6; the oil outlet hole 4 is connected to the threaded hole of the nut body 7 are connected; the oil injection hole 4 and the oil outlet hole 5 are located on the same straight line; the nut body 1 is provided with a photoresistor 8 and a power supply 9; the photoresistor 8 is provided with a light shield 10; the nut body 1 A groove 11 matching the photoresistor 8 is provided on the side of the side; the photoresistor 8 is arranged in the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com