Method and device for assembling drawn cup needle roller bearing

A technology for stamping outer rings and needle roller bearings, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., and can solve problems such as uneven precision, ineffective rotation, and missing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0017] Example.

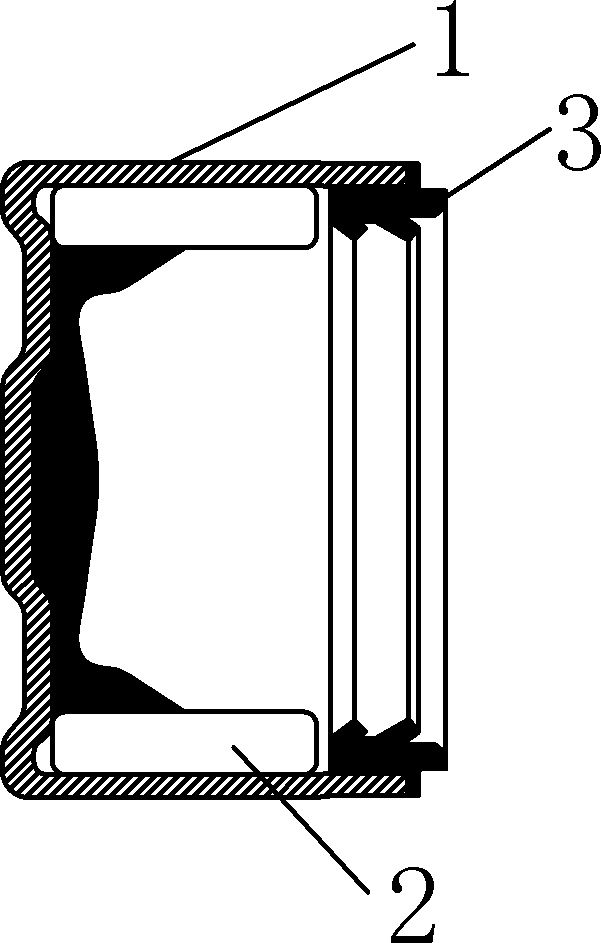

[0018] The structure of the drawn outer ring needle roller bearing is as follows: figure 1 As shown, including - outer ring 11, needle roller 12 and rubber oil seal 13.

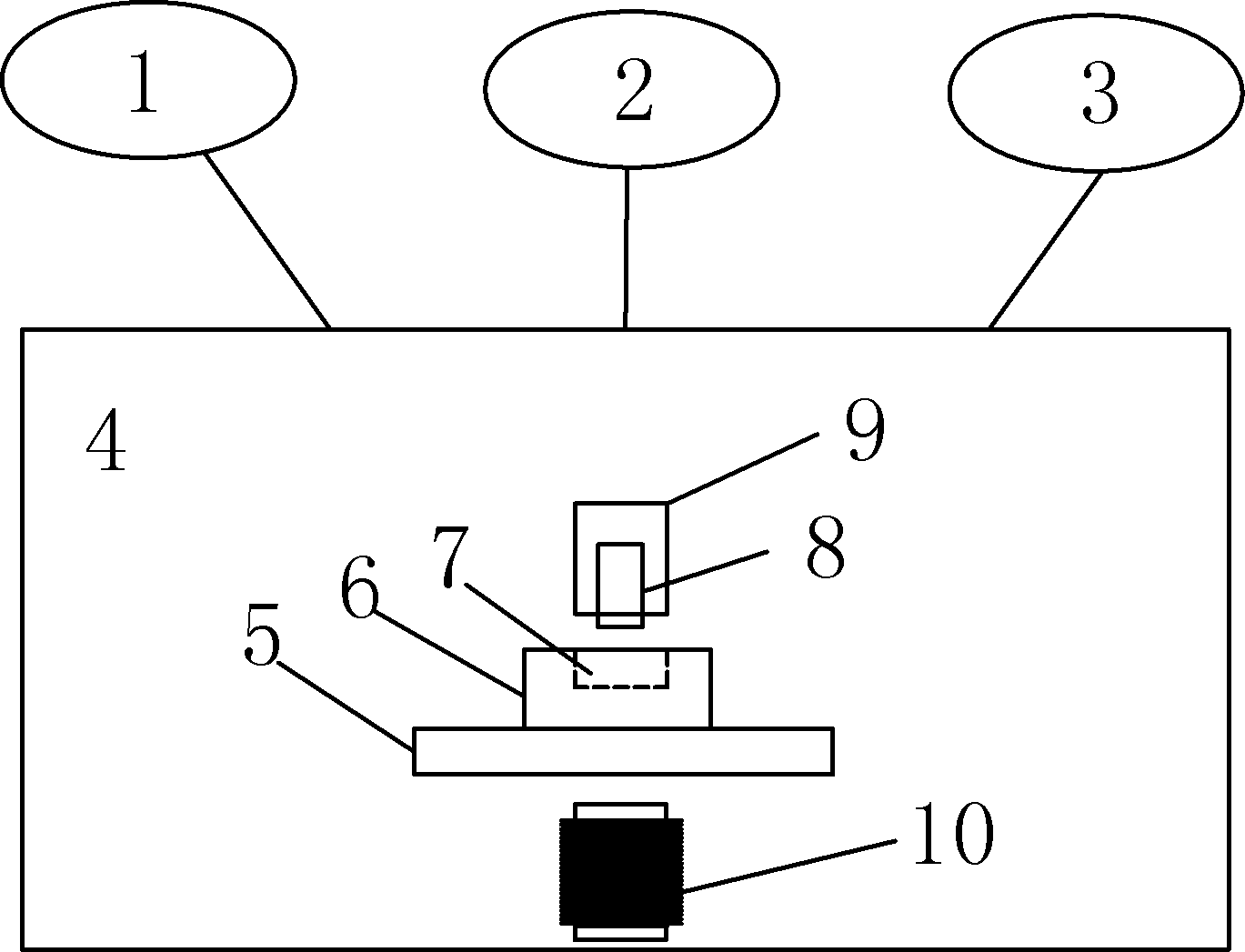

[0019] A method for assembling needle roller bearings with stamped outer rings: place the stamped outer rings, needle rollers and rubber oil seals in vibrating pans respectively, arrange the materials in an orderly orientation and drop them through the vibrating pans, and drop the stamped outer hoops one by one into the assembler Position, and press into the mold, then drop the needle roller into the stamped outer ring, then roll into the rubber oil seal, and finally press to complete the assembly of the bearing. The vibration frequency of the vibrating plate is controlled by the PC to control the falling speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com