Device and method for rapidly preparing multi-component alloy material with continuously-changed components through microwaves

A multi-element alloy and microwave technology, applied in the field of alloy material processing, can solve the problems of excessive concentration, slow heating rate, uneven heating, etc., and achieve the effects of saving space, fast heating speed, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

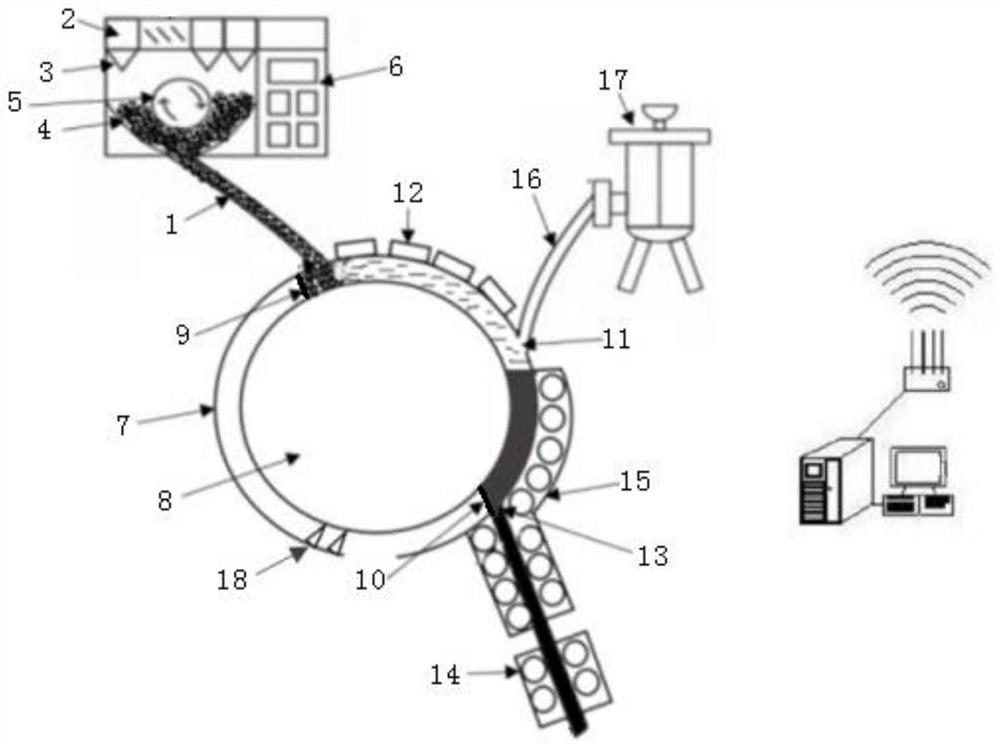

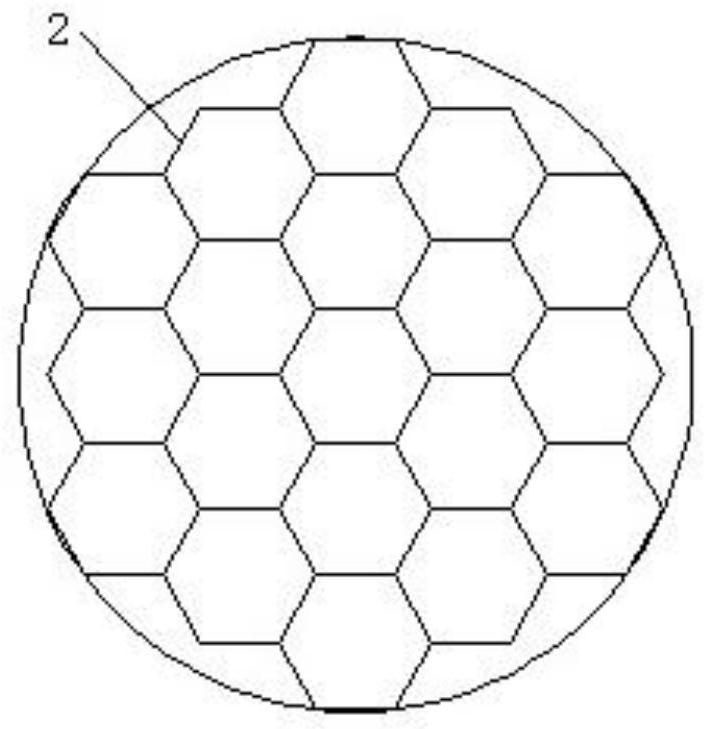

[0030] figure 1 It shows a device for rapid preparation of multi-component alloy materials with continuously changing composition by microwave, including a metal powder storage system, a feeding pipeline 1, a microwave melting system and a control system. The metal powder storage system is a box-type storage, and the box-type storage The top is provided with a plurality of metal powder storage bins 2, the metal powder storage bin 2 stores the metal powder of a single element, for the convenience of its installation, such as figure 2 As shown, its cross section is a regular hexagon, so the number of metal powder storage bins 2 placed in the same area is more. A flow control valve 3 is arranged at the bottom of each metal powder storage bin 2, a powder mixer 4 is arranged below the flow control valve 3, a stirring device 5 is arranged in the powder mixer 4, and a control panel 6 is arranged on the box-type storage.

[0031] The microwave melting material system includes an out...

Embodiment 2

[0044] Weigh 600 mesh 5kg metallic pure aluminum powder, 600 mesh 1.5kg metallic pure magnesium powder, 600 mesh 1.5kg metallic pure gallium powder, 600 mesh 1.5kg metallic pure tin powder. Put the above-mentioned raw material powder into the metal powder storage bin 2 in the box-type storage respectively for subsequent use.

[0045] The flow control valve 3 is controlled by the control system, so that the powders in the four metal powder storage bins 2 flow down at different speeds, and at the same time, the rotation of the stirring device 5 in the powder mixer 4 is controlled, so that the Mg, Ga, and Sn contents range from 0% to 0%. Fully mixed powder of Al-Mg-Ga-Sn metals varying in the range of 5%.

[0046] At the same time, the control roller 8 rotates, and the mixed powder enters the filling area 11 through the feeding pipeline 1 . The microwave generator 12 is controlled to heat the powder, and it flows downwards driven by the rotation of the roller 8. When the roller ...

Embodiment 3

[0049] Weigh 200 mesh 5kg metal pure aluminum powder, 200 mesh 2kg metal pure magnesium powder, 200 mesh 2kg metal pure gallium powder, 200 mesh 2kg metal pure tin powder, 200 mesh 2kg metal pure indium powder. Put the above-mentioned raw material powder into the metal powder storage bin 2 in the box-type storage respectively for subsequent use.

[0050] The flow control valve 3 is controlled by the control system, so that the powders in the five metal powder storage bins 2 flow down at different speeds, and at the same time, the stirring device 5 in the powder mixer 4 is controlled to rotate, and then the contents of Mg, Ga, Sn, and In are obtained from 0 % to 8% Al-Mg-Ga-Sn-In metal well mixed powder.

[0051] At the same time, the control roller 8 rotates, and the mixed powder enters the filling area 11 through the feeding pipeline 1 . The microwave generator 12 is controlled to heat the powder, and it flows downwards driven by the rotation of the roller 8. When the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com