Single sphere drive shaft assembly for constant velocity universal joint

A constant velocity universal joint and drive shaft technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem of increasing the manufacturing cost of cars, the complex structure of the constant velocity universal joint drive shaft assembly, and the assembly process. Many problems, to achieve the effect of avoiding fatigue aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

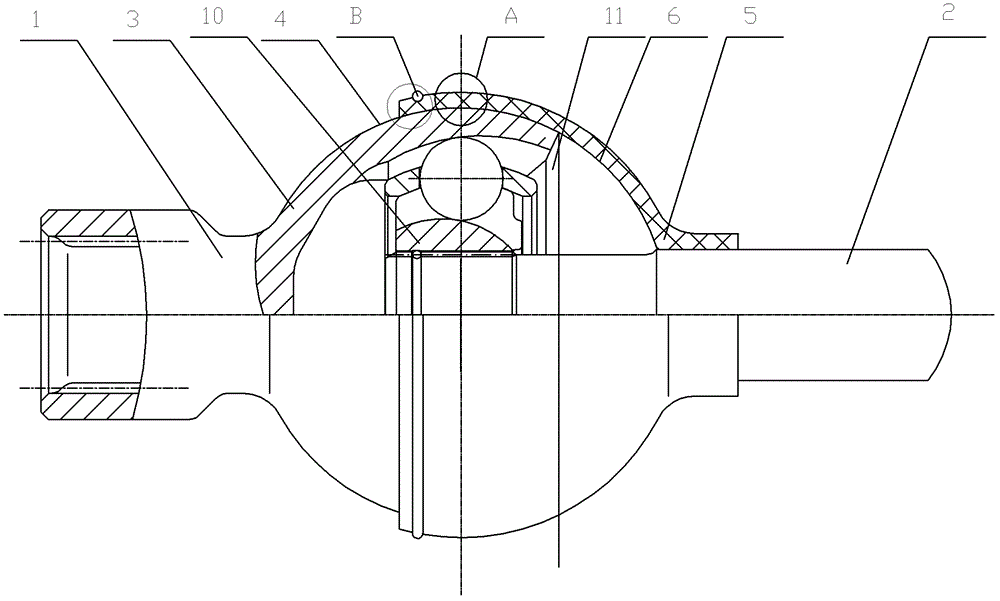

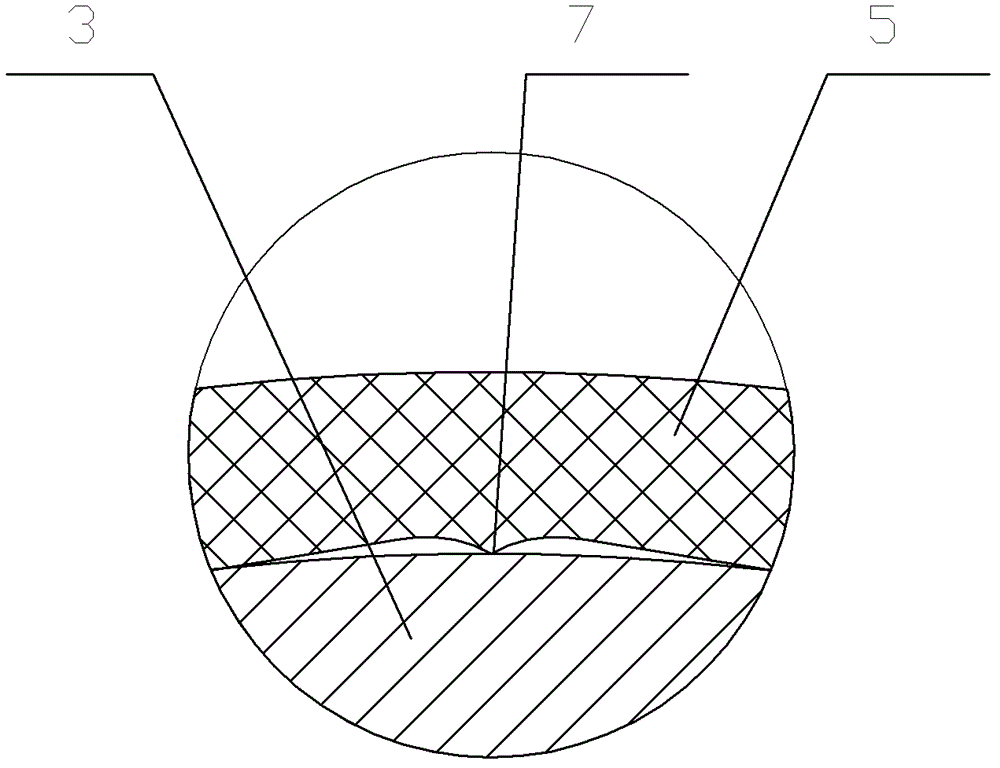

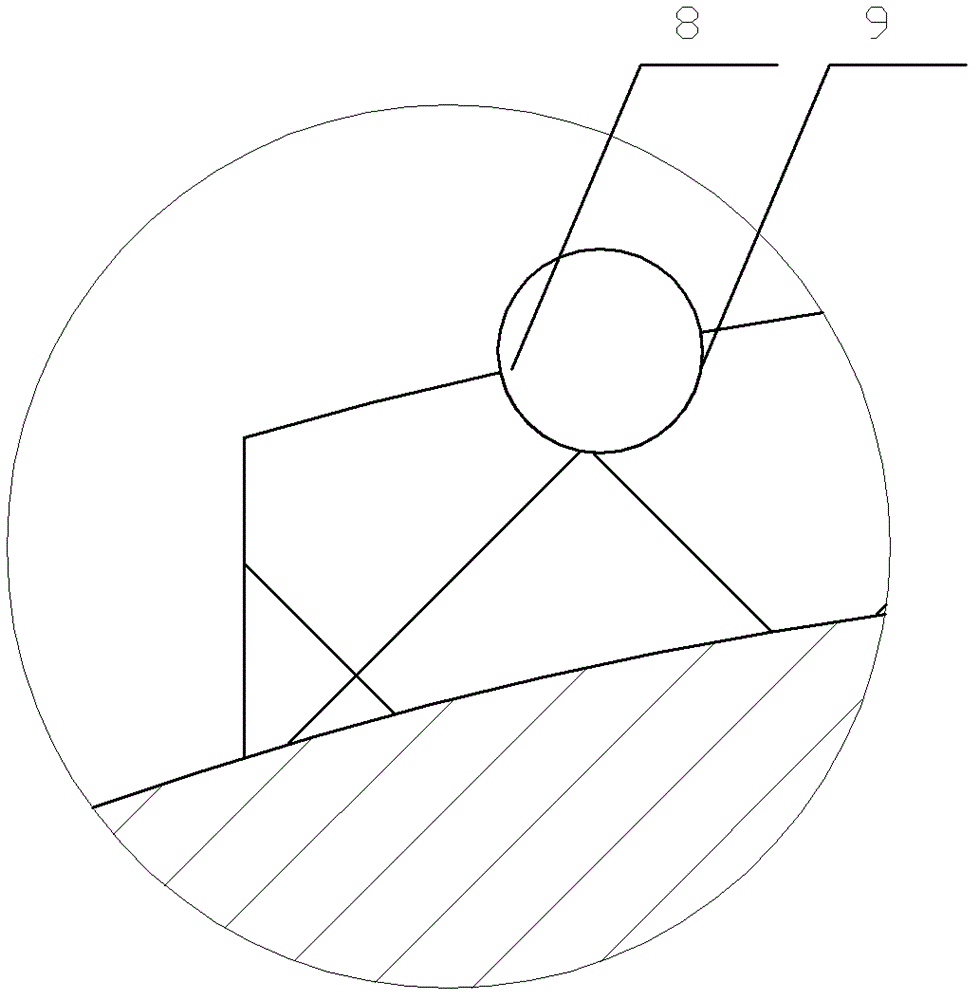

[0017] Such as figure 1 As shown, a single-sphere constant velocity universal joint drive shaft assembly of the present invention includes a universal joint 1 and a half shaft 2. The outer surface of the housing 3 of the universal joint has an outer spherical portion 4; A dust jacket 5, the inner surface of the dust jacket 5 has an inner spherical surface 6 compatible with the outer spherical surface 4, one end of the dust jacket is fixed on the half shaft 2, and the other end is lapped on the On the outer spherical portion 4 of the housing and when the housing rotates relative to the dust cover, the opening end 11 of the housing always falls in the dust cover 5 . In the present invention, the dustproof cover is lapped on the outer spherical surface of the housing, and when the housing rotates relative to the dustproof cover, the open end of the housing always fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com