Heating system for reducing floor impact sound using heating piping method

A heating system and impact sound technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as reducing floor impact sound, and achieve the effects of preventing release, excellent weather resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

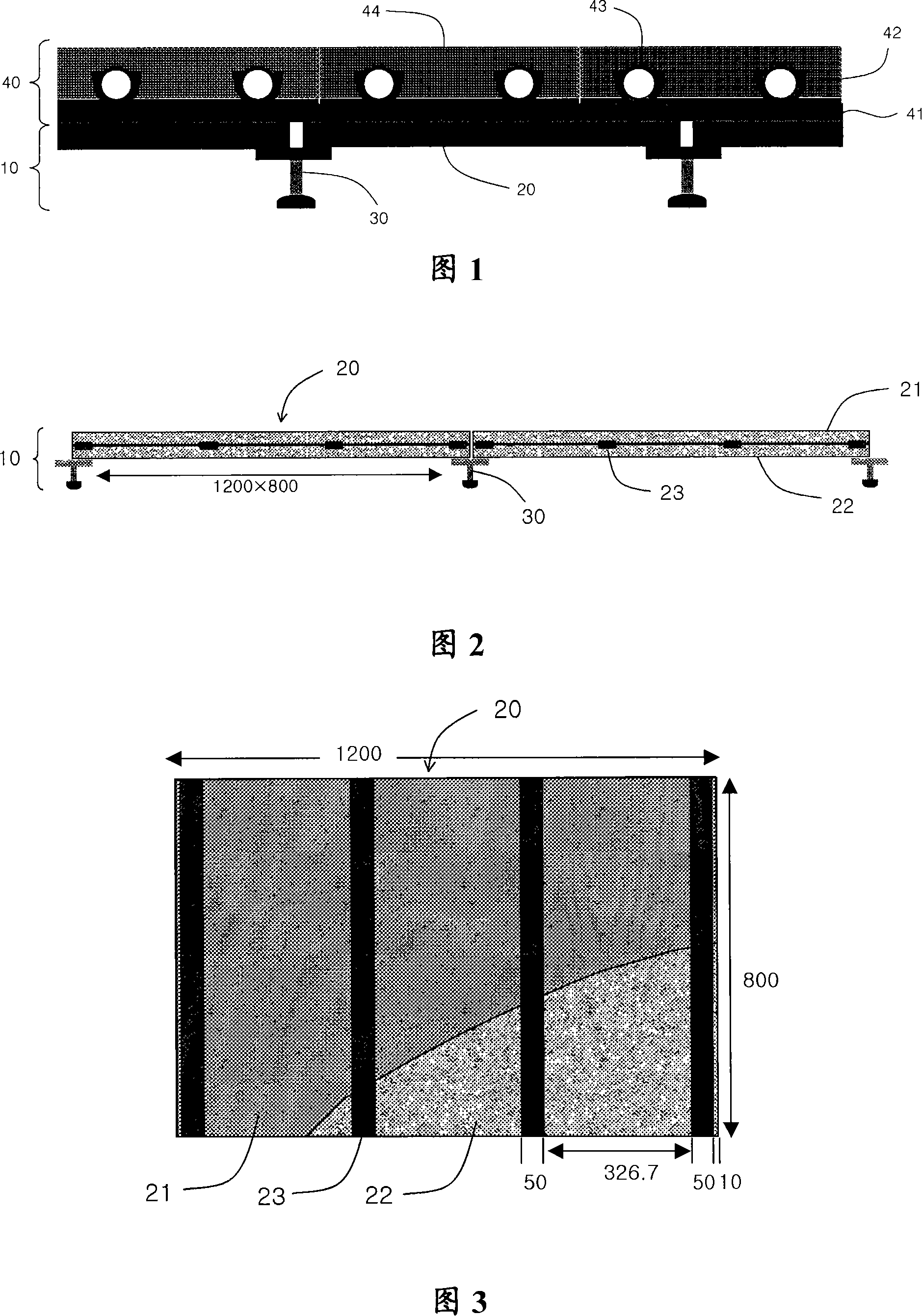

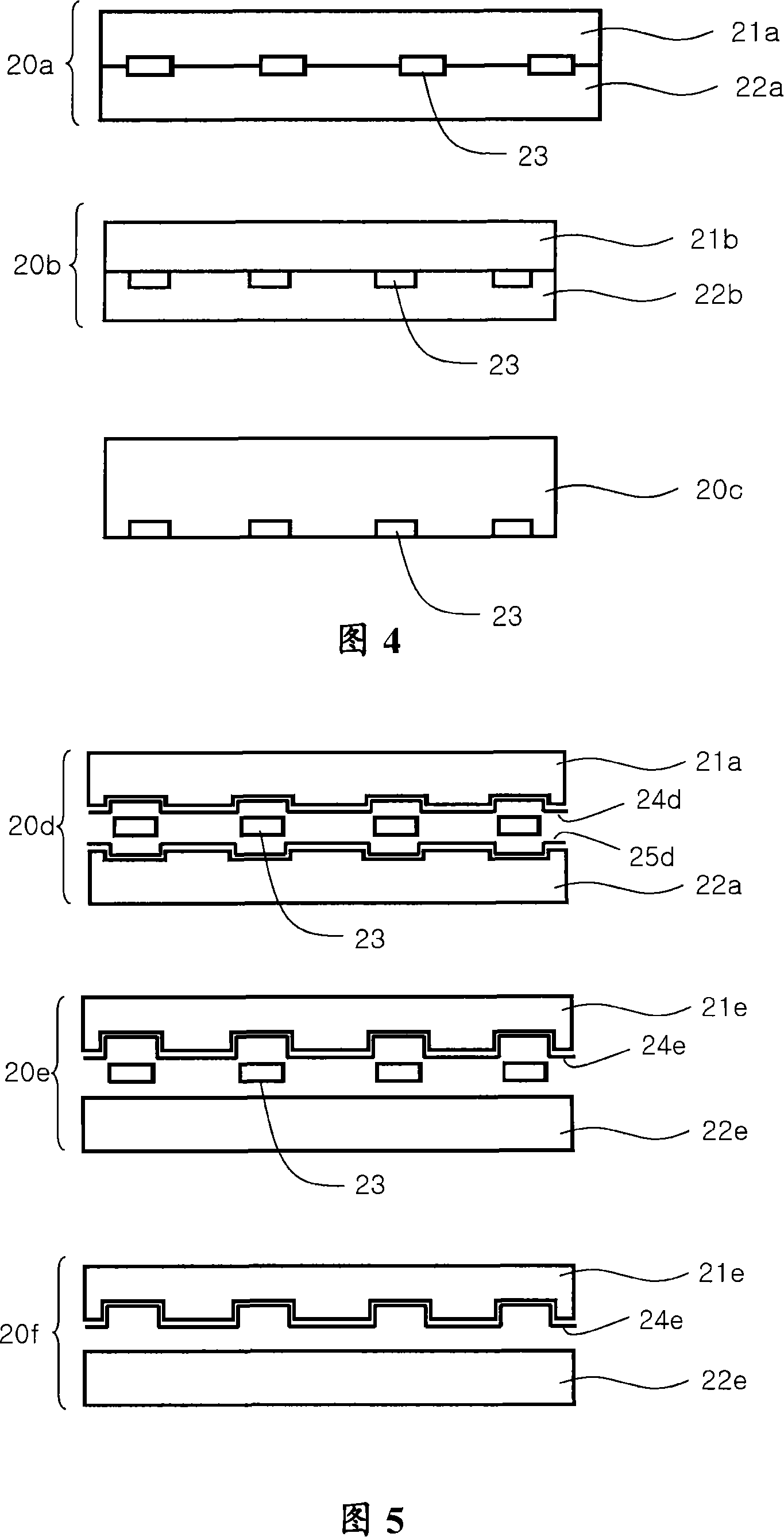

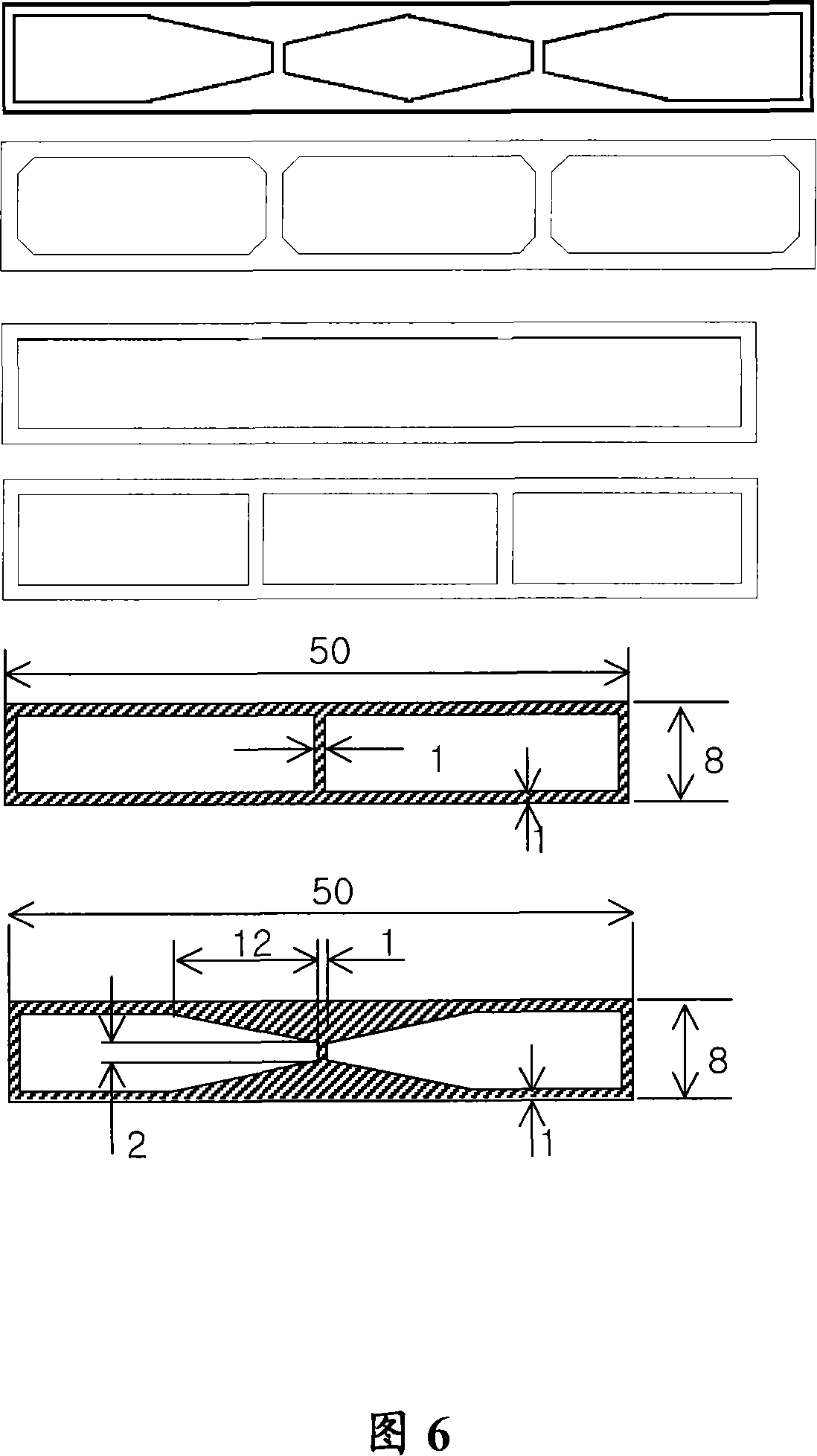

[0078] A heating system having a structure as shown in FIG. 1 was constructed, but its lower part was constructed to have a structure of a double bottom layer 10 as shown in FIG. 2 . Particle boards with a thickness of 18mm are used as the upper sheet material 21 and the lower sheet material 22, and four quadrangular aluminum rods having a rib structure with dimensions (unit: mm) as shown in FIG. The top plate 20 of the structure shown in FIG. 3 .

[0079] First, form narrow and long quadrangular grooves at four positions on the bottom surface of the upper sheet material 21 and the top surface of the lower sheet material 22 respectively along the longitudinal direction of its short side, then insert the aluminum rod in each narrow and long groove, and then Bonded and pressed to prepare a top plate 20 having a thickness of 36 mm.

[0080] Next, the wet heating layer 40 was constructed as follows. An expandable polystyrene (EPS) layer 41 having a thickness of 10 mm was dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com