Welding and positioning clamp for electromagnetic driving component

An electromagnetic drive and welding positioning technology, which is applied in the field of welding positioning fixtures and welding positioning fixtures for electromagnetic drive components, can solve the problems of poor solder joint quality, influence of assembly process, low qualification rate, etc., so as to improve labor productivity and avoid artificial Factors, the effect of a good stress condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

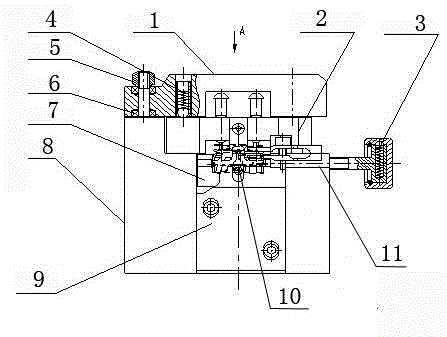

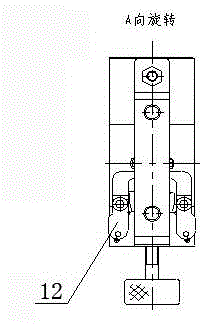

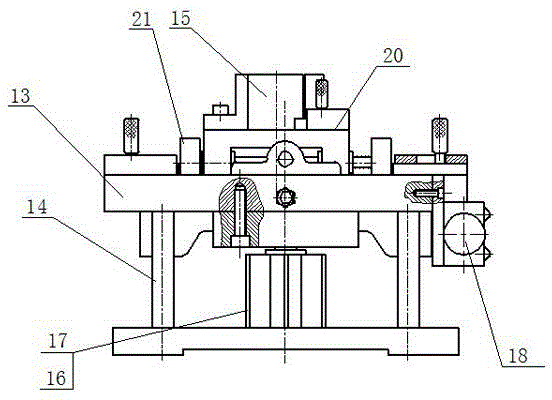

[0021] The present invention is described in detail below in conjunction with accompanying drawing embodiment:

[0022] As shown in the figure, the electromagnetic drive assembly welding positioning fixture of the present invention is composed of a clamping mechanism, a welding spot positioning mechanism 13 and a pneumatic adjustment device 16. The clamping mechanism is provided with a cavity for placing the electromagnetic drive assembly 10 and a fixed device, the clamping mechanism includes a swing arm beam 1, a pressing block assembly 2, an adjustable block 7, a push block 11, an adjustable knob 3, a clip seat 8, two side splints 9, two adjustable clips 12, the two The side splint 9 is connected to the groove in the middle part of the front and rear sides of the clamp seat 8. The connection hole between the side clamp plate 9 and the clamp seat 8 is a waist-shaped round hole, which is fixedly connected by bolts, and the relative position can be adjusted as required. The adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com