Array type supporting auxiliary device for electrolytic machining of large-size weak-rigidity thin-wall part

An auxiliary device and weak stiffness technology, applied in the direction of electric processing equipment, electrochemical processing equipment, accessory devices, etc., can solve problems such as difficulty in ensuring consistent and stable wall thickness, improve applicability and scalability, suppress mechanical chatter, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

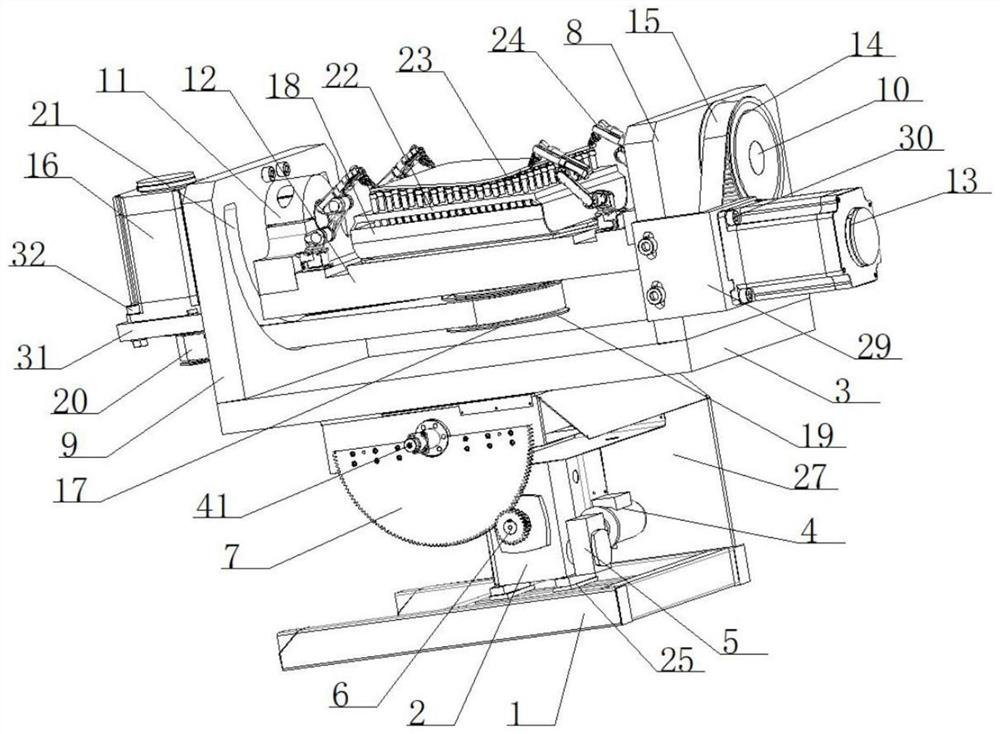

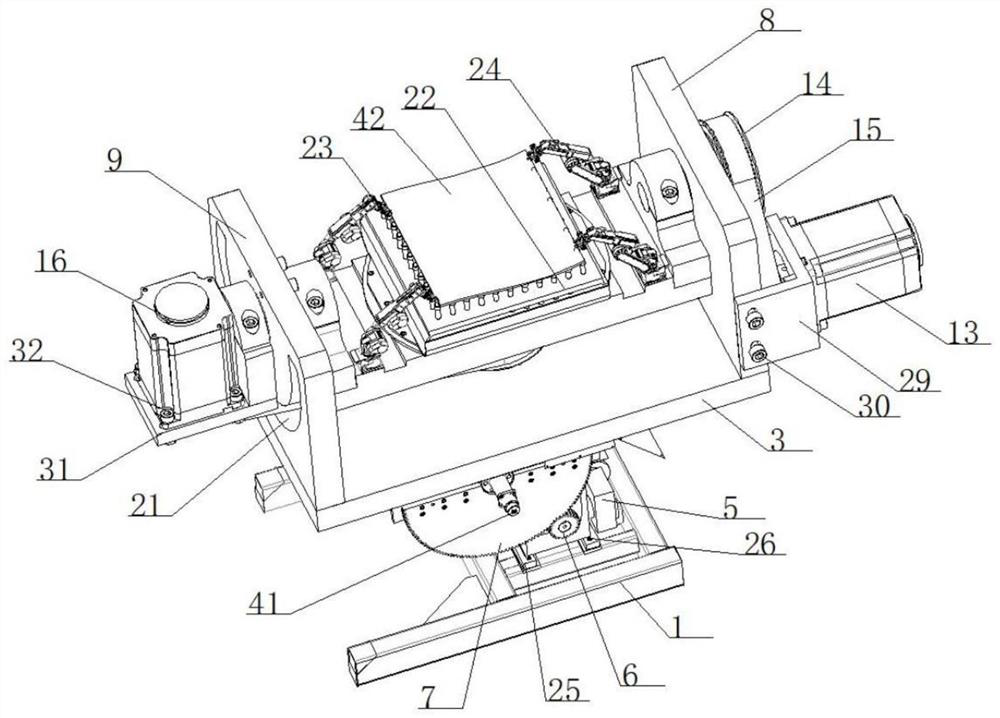

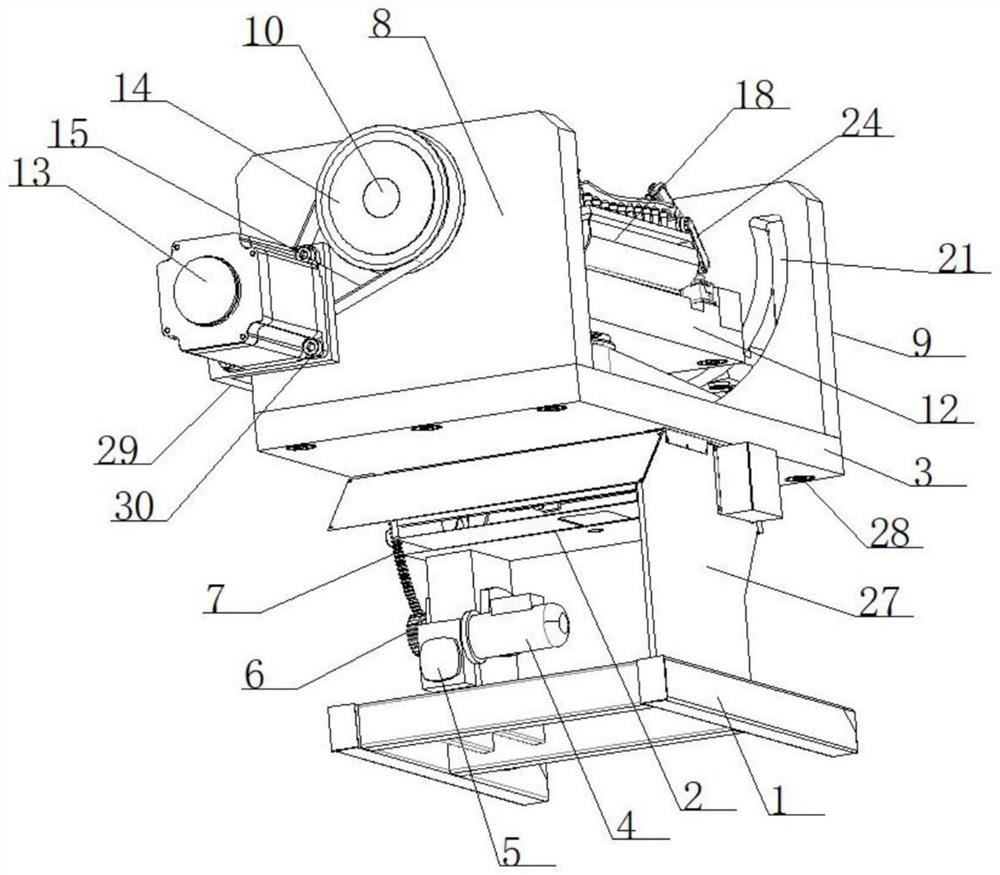

[0038] refer to Figure 1-5 , an array support auxiliary device for electrolytic processing of large-sized weak rigidity thin-walled parts, including a base 1, a mounting frame 2 and a mounting plate 3, the mounting frame 2 is fixedly connected to the top of the base 1, and the bottom of the mounting frame 2 is fixedly connected to multiple Locking block 25, the top of locking block 25 and base 1 is fixedly connected by a plurality of locking bolts 26, facilitates fixing and dismounting installation frame 2, the top of base 1 is provided with the locking groove corresponding to locking block 25, and base 1 The top of one end is fixedly connected with a protective plate 27 corresponding to the installation frame 2, which plays a protective role;

[0039] In the present invention, the top of the mounting plate 3 and the mounting frame 2 is rotatably connected through a rotating rod 41 for driving the mounting plate 3 to rotate, and one side of the mounting frame 2 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com