Heat pump defrosting system in winter

A technology of heat pump and heat source, applied in the field of heat pump winter defrosting system, which can solve the problems of high-grade electric energy consumption and non-conforming to low-carbon energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] like Figure 4 and Figure 5 As shown, the pcm module and the indoor coil 111 of the indoor unit are made in the form of a sleeve 11 and installed on the heat dissipation fins 12 of the indoor unit; the pcm medium 112 of the pcm module surrounds the sleeve 11 outside. The indoor unit fan stops during defrosting. The heat required for defrosting is all provided by the storage heat and latent heat of phase change of the pcm medium. In the normal heating stage before defrosting, the pcm medium is heated by the indoor return air, and the pcm medium is in a liquid state. After switching to the defrost mode, the evaporation temperature of the indoor unit is lower than the phase transition temperature of the pcm medium, so the solution is feasible. In order to increase the heat exchange between the indoor unit and the medium in the pcm module, copper fins are evenly installed in the casing.

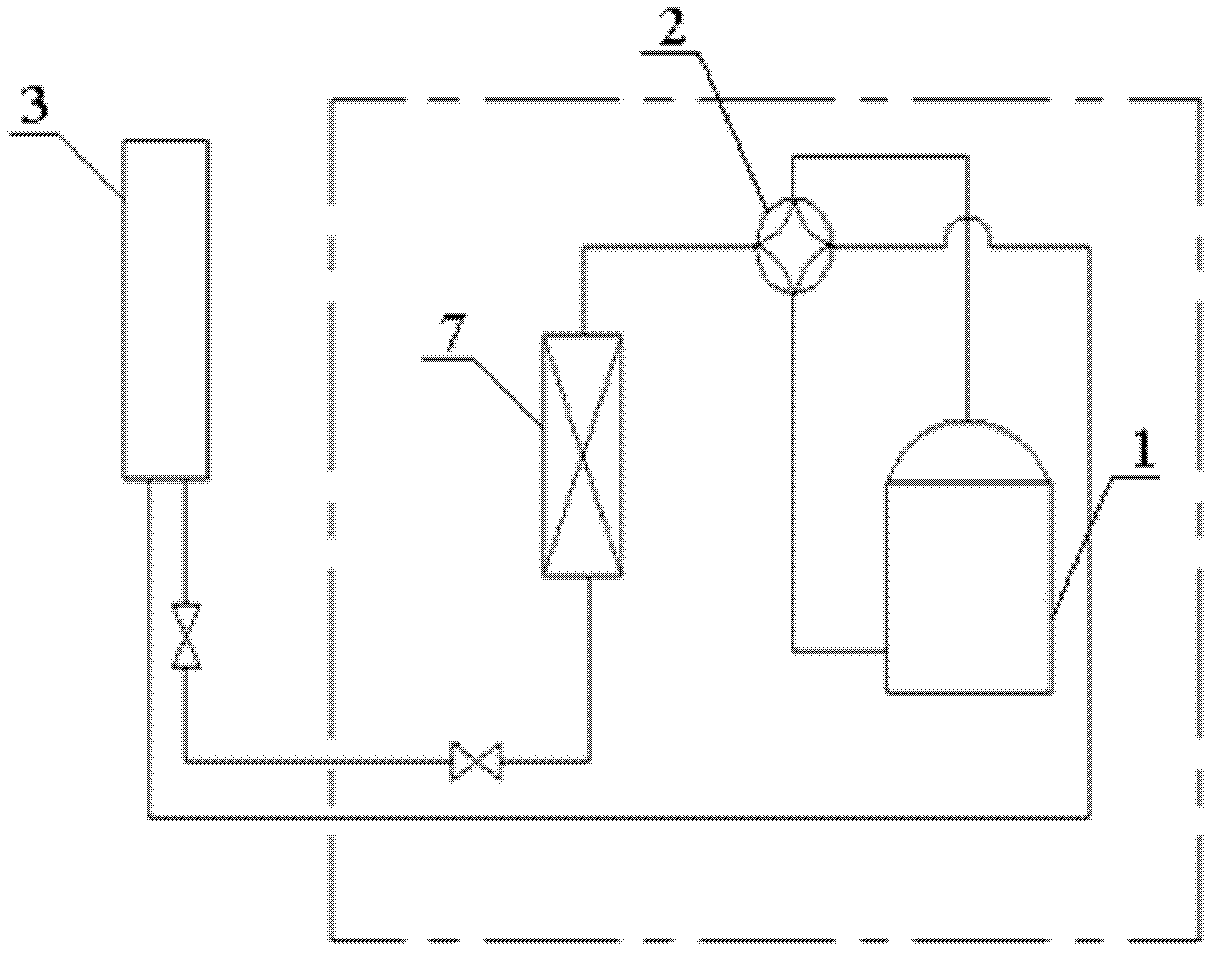

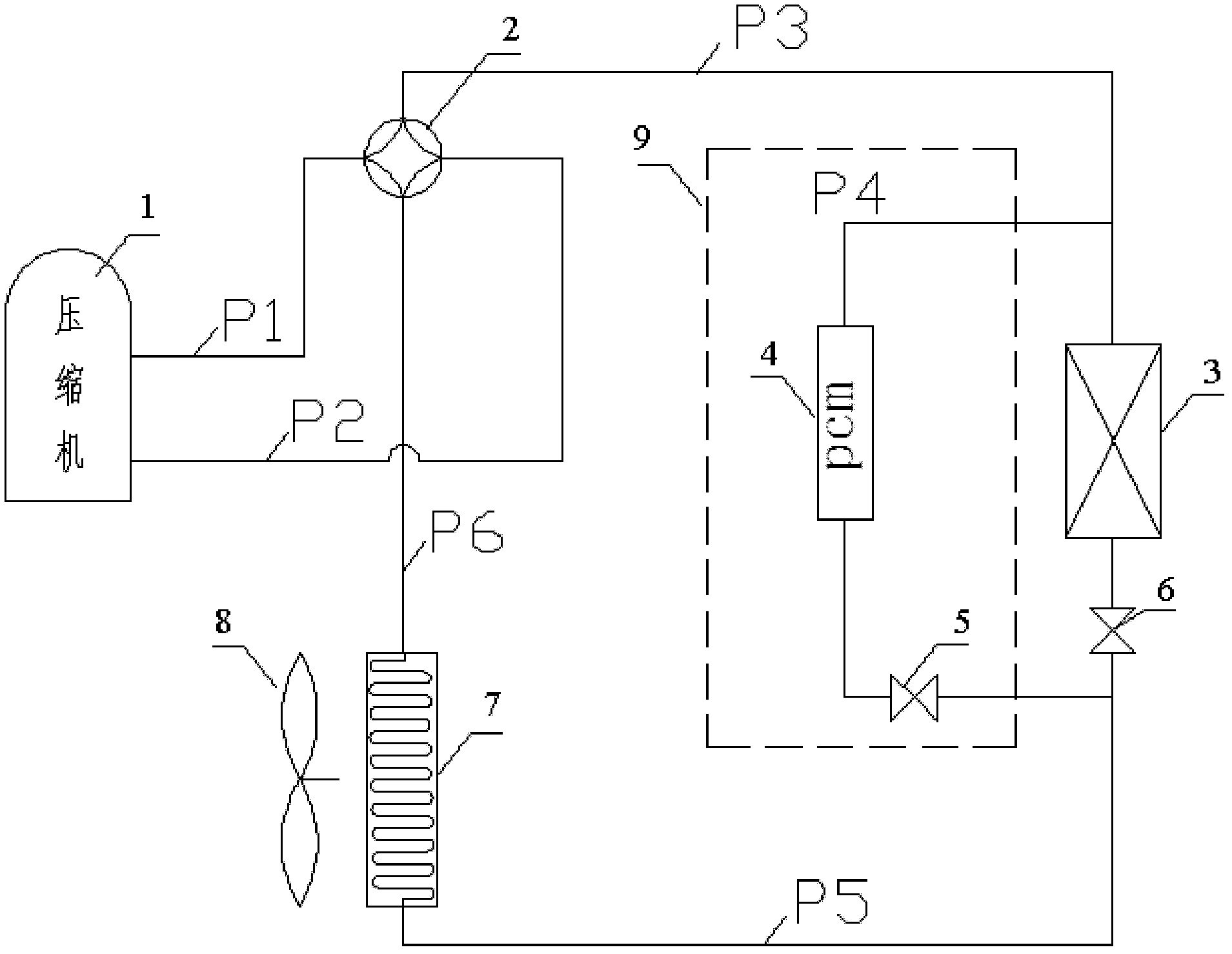

[0027] see image 3 (There is no part 9 at this time), the heat pump starts norm...

Embodiment 2

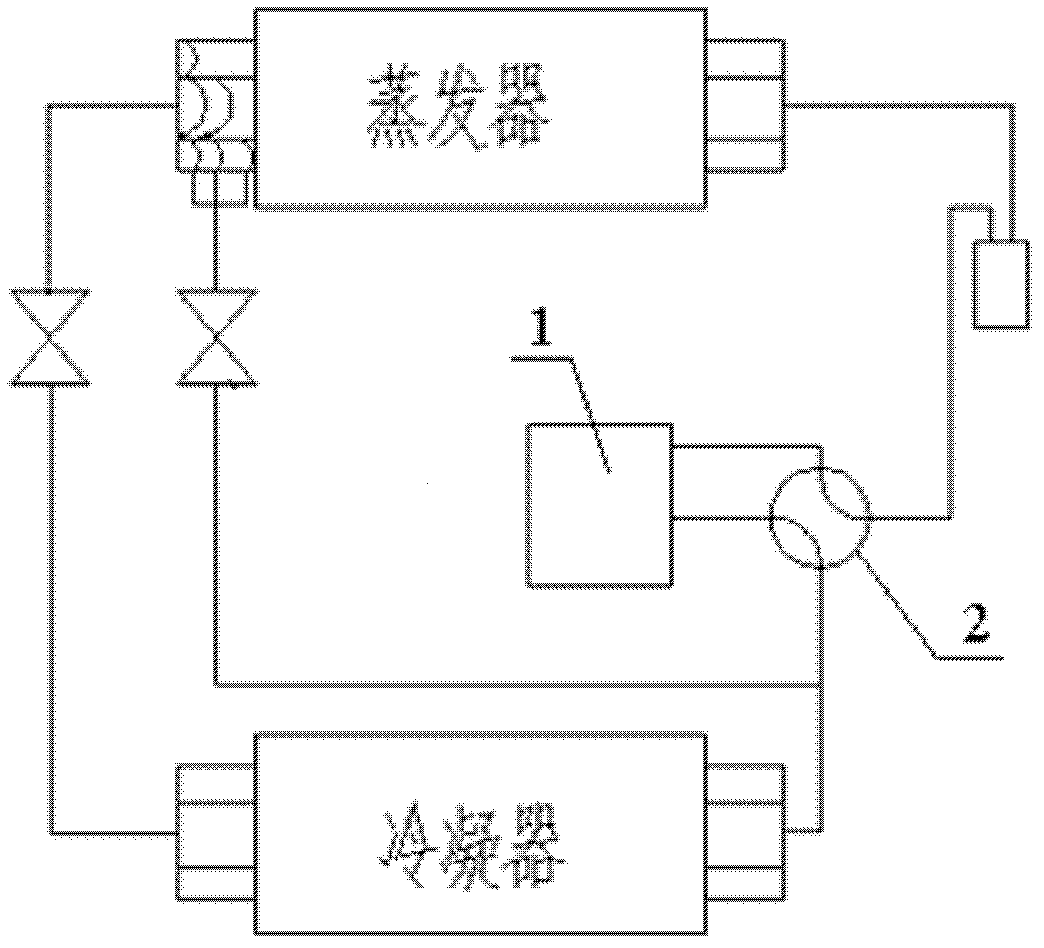

[0030] like Image 6 As shown, the pcm module and the indoor coil 111 of the indoor unit are arranged independently; the pcm module 4 is installed at the air outlet of the indoor unit; the indoor coil 111 is installed on the heat dissipation fins 12 of the indoor unit superior. like Figure 7 and Figure 8 As shown, the pcm module is a shuttle type or a sheet type; the outer periphery of the pcm module is a metal sheet 114, and the inside is a pcm medium 112, and the pcm medium 112 is provided with a refrigerant pipeline for connecting with the condenser of the indoor unit .

[0031] see image 3 (At this time, there is part 9), the heat pump starts normally and runs in a frost-free state. At this time, the circuit controls the throttle valve 5 to close and 6 to open. The refrigerant exits the compressor through pipelines P1 and P3 and then enters the indoor unit 3. The principle at this stage is the same as that of Scheme 1; Image 6As shown in the figure, the pcm modul...

Embodiment 3

[0034] like Figure 4 and Figure 5 As shown, the pcm module and the indoor coil 111 of the indoor unit are made in the form of a sleeve 11 and installed on the heat dissipation fins 12 of the indoor unit; the pcm medium 112 of the module is surrounded by the sleeve 11 . Another pcm module is arranged independently of the indoor coil 111 of the indoor unit, and is installed at the air outlet of the indoor unit.

[0035] The operation is basically the same as in Example 2, the difference is the defrosting stage image 3 The middle solenoid valves 5 and 6 are both open, and the refrigerant absorbs heat not only from the pcm medium on the casing, but also from the pcm medium at the tuyere of the indoor unit.

[0036] Describe the present invention with an example below, choose McQuay 1HP split type heat pump air conditioner to calculate, and its specification parameter is as follows:

[0037]

Cooling capacity (kw)

Heating capacity (kw)

Cooling power (kw) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com