Device and method for testing precision retaining ability of ball screw assembly

A ball screw pair and precision maintenance technology, applied in the detection field, can solve the problems of ball screw test and detection that have not yet been found, and achieve the effects of convenient operation and detection, good market prospects, and convenient adjustment of loading force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention provides a ball screw pair precision retention test device and method, which can be used for the test and detection of the ball screw pair precision retention.

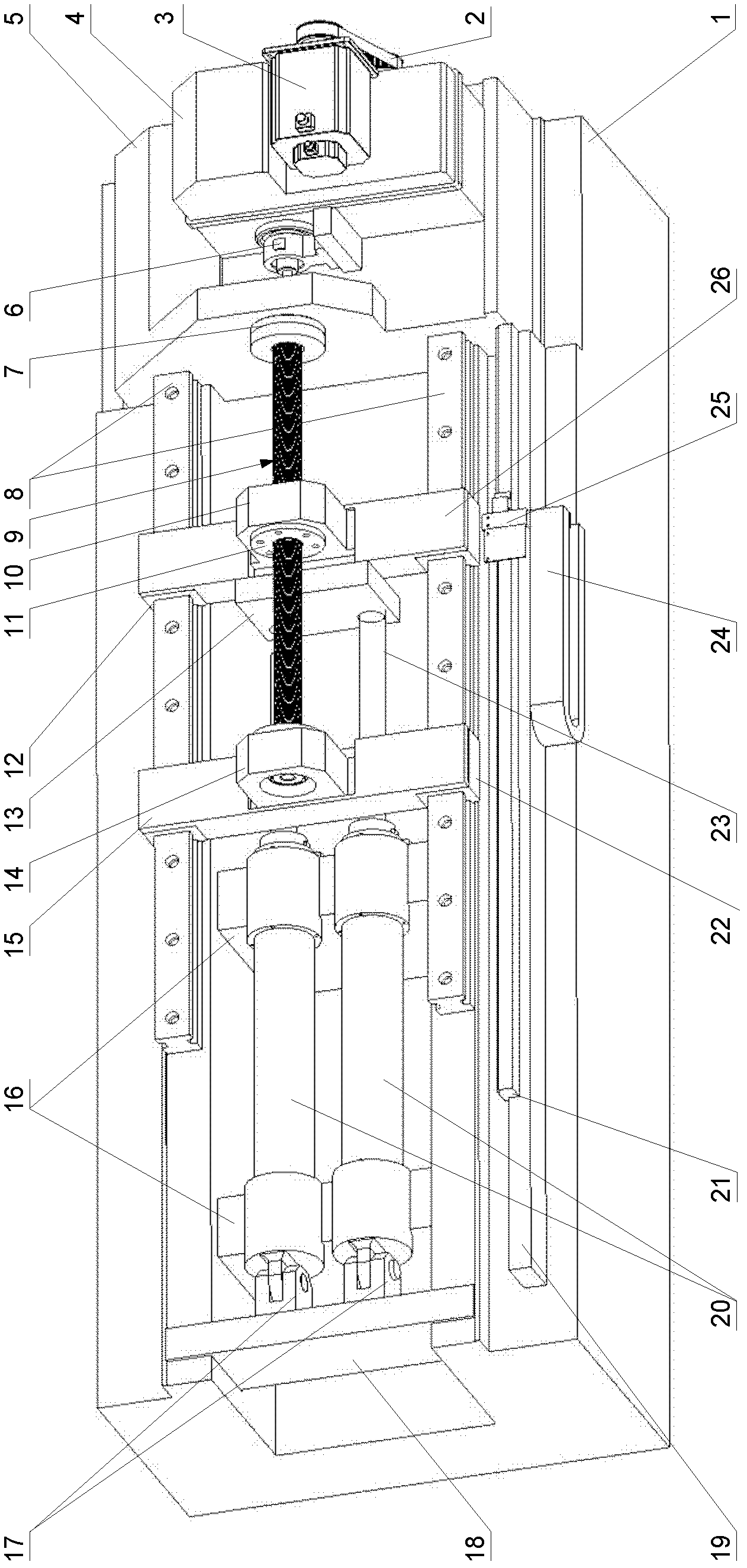

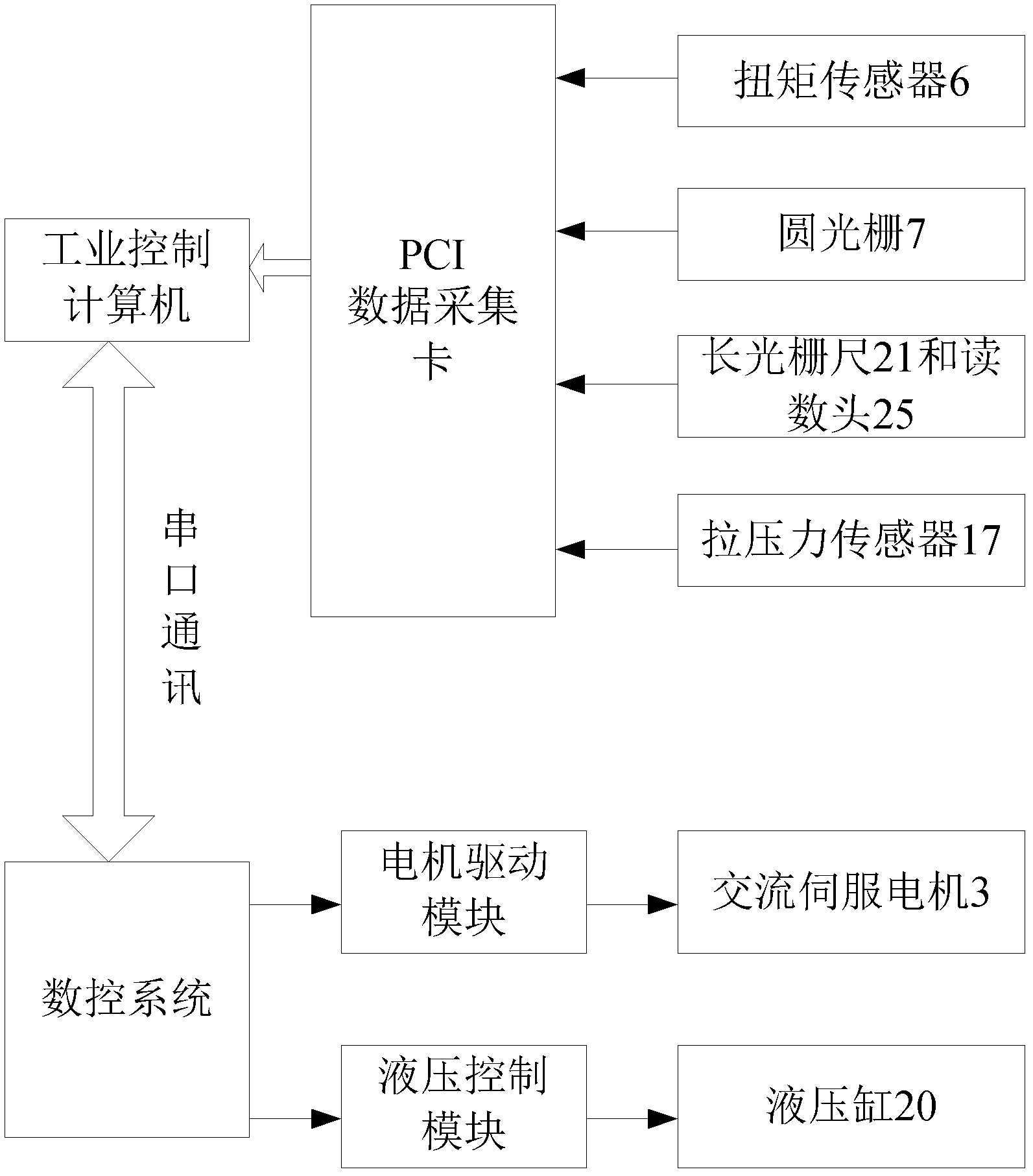

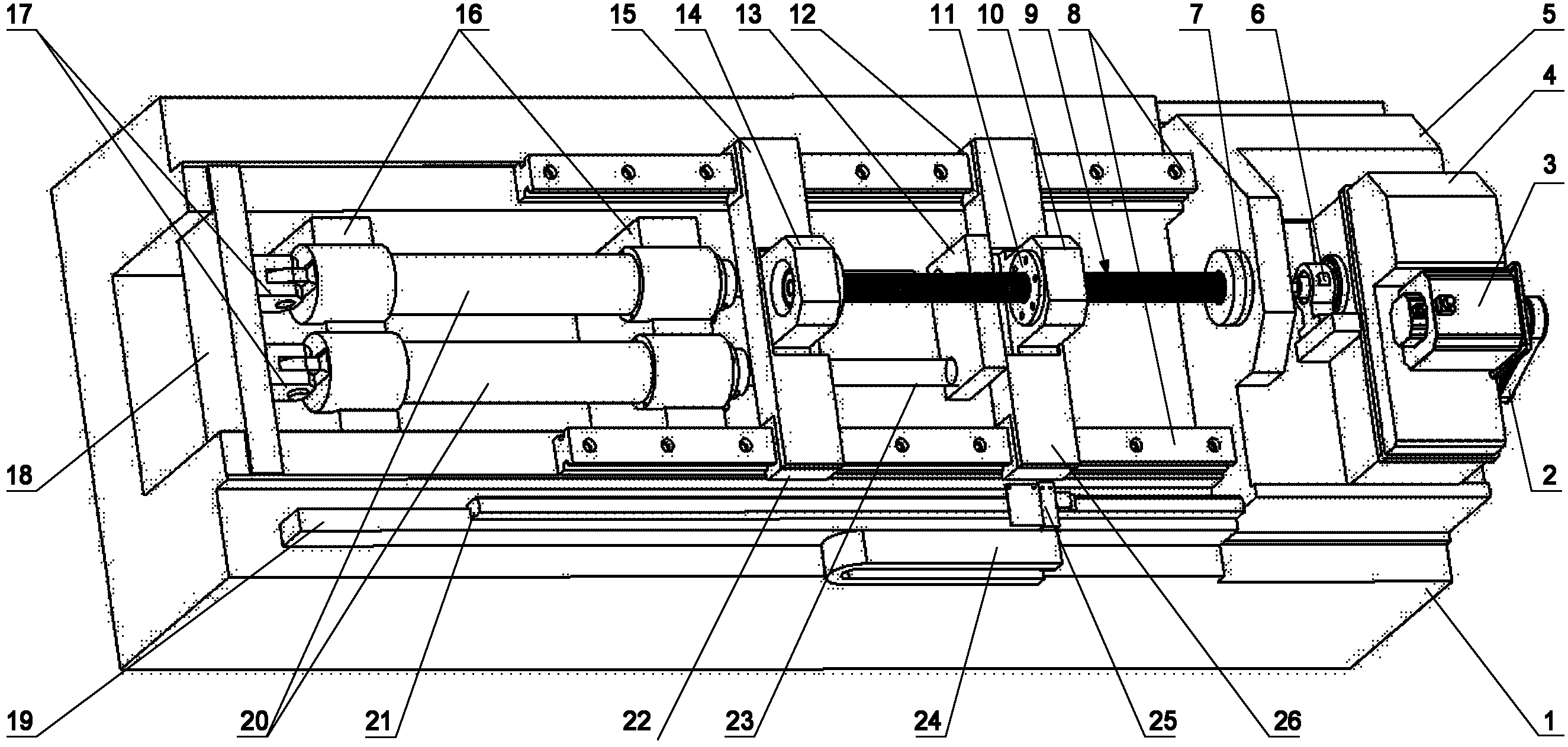

[0017] to combine figure 1 , a ball screw pair accuracy maintenance test device, including a bed 1, a synchronous belt transmission mechanism 2, an AC servo motor 3, a reducer 4, a head frame 5, a torque sensor 6, a linear guide rail 8, and a measured screw 9 , nut seat 10, nut 11, first group of sliders 12, push plate 13, tailstock 14, fixed plate 15, support plate 16, pull pressure sensor 17, baffle plate 18, hydraulic cylinder 20, second group of sliders 22 , hydraulic cylinder extension rod 23, slide plate 26;

[0018] The head frame 5 is fixedly installed on one end of the bed 1, the reducer 4 is fixedly installed on the head frame 5, the AC servo motor 3 is fixed above the reducer 4, and the output shaft of the AC servo motor 3 is connected with the synchronous belt transmission mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com