Reverse engineering computer-aided design (CAD) modeling method based on three-dimensional sketch

A technology of reverse engineering and modeling methods, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effects of improving stability and reliability, easy implementation, and simple algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

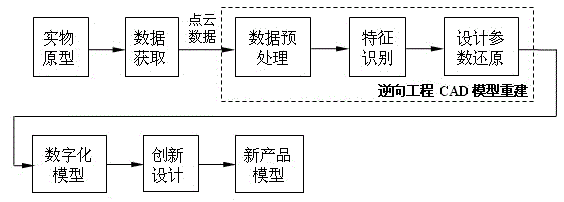

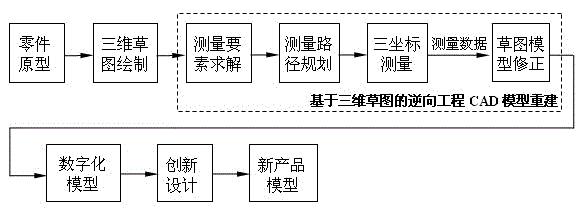

[0033] Such as figure 2 As shown, the physical prototype is first measured to obtain data, and then the reverse engineering CAD model is reconstructed to obtain the digital model of the physical prototype, and then the innovative design is carried out based on the digital model, and finally a new product model is formed. Described acquisition data, then carry out reverse engineering CAD model reconstruction to draw three-dimensional sketch, then carry out the reverse engineering CAD model reconstruction based on three-dimensional sketch, the steps of this method are as follows:

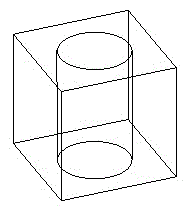

[0034] 1) According to the geometric characteristics of the physical parts, select a group of solid primitives in the way of interactive design, and construct the 3D sketch model of the solid parts through geometric transformation operations and Boolean operations;

[0035] 2) Based on the 3D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com