Switching controller of flyback power converter and its controller and control circuit

A power converter and switching circuit technology, applied in output power conversion devices, DC power input to DC power output, control/regulation systems, etc., can solve large-space, high-output line ripple nonlinear power conversion operations And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] In order to make the above-mentioned objects, features and advantages of the present invention more clearly understood, a preferred embodiment is exemplified below and described in detail in conjunction with the accompanying drawings.

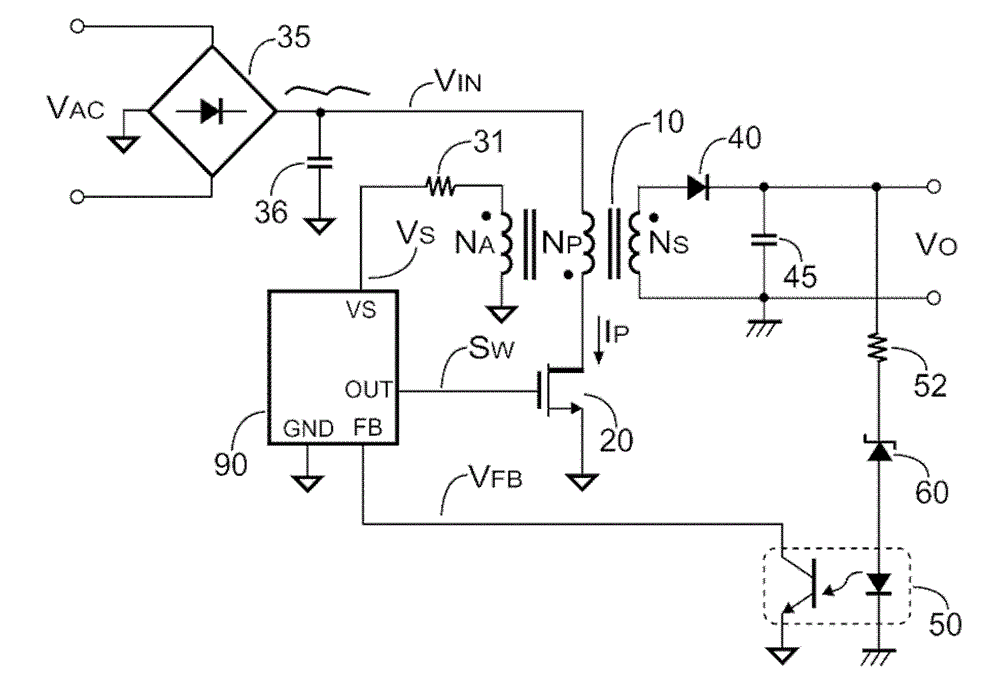

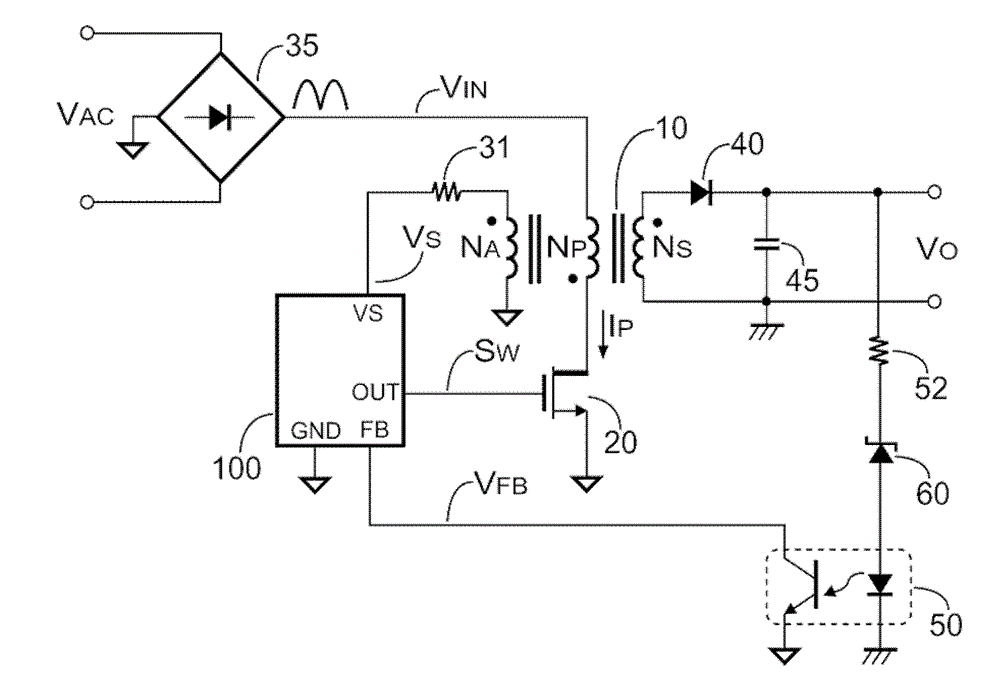

[0122] Figure 1B A flyback power converter according to an embodiment of the present invention is shown. Figure 1A and Figure 1B The only difference is that, Figure 1B The embodiment is to use the switching controller 100 without using Figure 1A input capacitor 36 to perform general output regulation of the power converter.

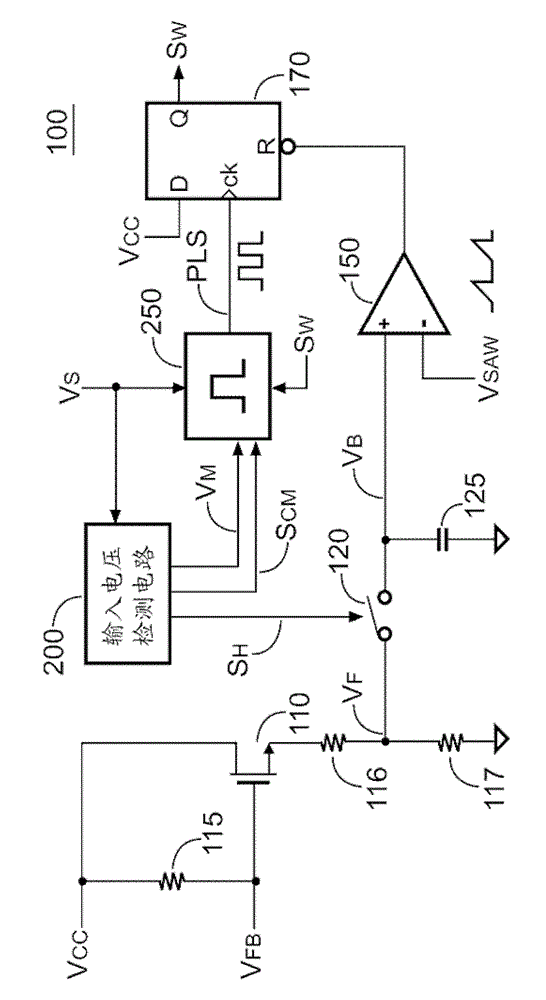

[0123] The output power P of the flyback power converter O can be expressed as:

[0124] P O = V O × I O = V IN 2 × T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com